- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XTIME

-

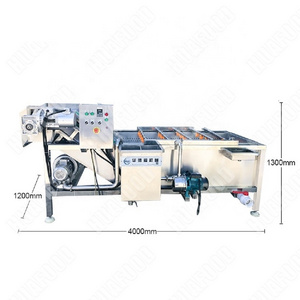

Dimension(L*W*H):

-

L2300*W1000*H1500mm

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

304 Stainless Steel

-

Usage:

-

sealing various of Bottles

-

Advantage1:

-

factory wholesale price

-

Advantage2:

-

high quality

-

Control:

-

PLC+ Touch Screen

-

Customzied:

-

Acceptable

-

Certification:

-

CE Certificate

-

Keywords:

-

Puff food filling machine

Quick Details

-

Application:

-

Beverage, Food, Medical, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, Cigarettes, Tobacco

-

Packaging Material:

-

Metal, Paper, Plastic

-

Voltage:

-

220V/50Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XTIME

-

Dimension(L*W*H):

-

L2300*W1000*H1500mm

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

304 Stainless Steel

-

Usage:

-

sealing various of Bottles

-

Advantage1:

-

factory wholesale price

-

Advantage2:

-

high quality

-

Control:

-

PLC+ Touch Screen

-

Customzied:

-

Acceptable

-

Certification:

-

CE Certificate

-

Keywords:

-

Puff food filling machine

Best Quality Factory Supply CE Automatic Canned Dog Pet Wet Food Canning Filling And Sealing Machine Production Line

Procedure:Empty cans feeding-material elevator-10 heads weigher-Rotary filling/Linear filling-can sealing-screw capping-labeling!

Packaging speed:

(1)with Linear Filling Machine:25-30 cans/min with high accuracy ≤ 0.5-2g.

(2)with Rotary Filling Machine:40-50 cans/min with high accuracy ≤ 0.5-2g.

It is suitable for various of granular products such as Puffed food, Slice Dried meat floss,Dried fish, cheese ball,chocolate ball,crispy snacks,,color sugar,popping candy,cashew nuts,peanut,nuts,pistachio, vegetable seeds,sunflower seed,dried fruit,chips,raisin,popcorn,rice,pepper,ect.

Used for packing in tin can, metal can, aluminum can, PET can,composite paper can.

| Model | XT-ZHC010 |

| Material | 304# Stainless Steel |

| Program control | PLC+Touch screen |

| Sealing Speed | 30-50 cans/min |

| Cap's Diameter | 30-130mm (can be customized) |

| Bottle's height | 50-200mm( can be customized) |

| Bottle's Diameter | 50-130mm(can be customized) |

| Power | 1KW |

| Air source | 0.6-0.8Mpa |

| Weight | 400KGS for multi head weigher |

| Voltage | Single phase 220V,50/60Hz |

Structure and performance specification

(1).The machine is suitable for sealing package of PET can,tin can,aluminum can,paper can, with aluminum easy open end/lid, thehn with screw top cap/lid/cover.

(2).All 304# stainless steel material adopts the electrical accessories with the international well-known brand.

(3).The design is reasonable and precise,and it can be designed into Double heads or Multi-heads screw capping machine according to the speed requirement,which can meet the needs of different enterprises.

Feature

1. The machine's appearance is made of 304# stainless steel material,its external shape is simple and beautiful,in line with the design requirement of lots of the standard production workshop.

2. Various accessories are processed precisely,production technology and industry,etc,have obtained the sediment for customer experience for a long time of the company and continuous improvement,its main parts adopts the unique design,high strength,low noise,good sealing performance.

3. The design of automatic production line is extremely easy to be make up the operation line combined with the,weighing,filling,capping or labeling system.

4. This product is mainly applicable to dustproof plastic lid sealing with round bottles,such as various PET plastic,metal,aluminum and paper cans,etc.Our machines are with advanced design,reasonable structure,and simple operation,which is an ideal packaging equipment for food,medicine,tea,chemical industry,etc.

The whole packaging line is combined by below machines:

1.Empty can feeder---to feed the empty can into the filling machine automatically

2. 10 Heads or 14 Heads Multi-head weigher(combination weigher)---for weighing system

3.Linear filling machine--for automatic filling in cans/bottles/jars/pots.

4.Automatic can sealing machine/can seamer/can seaming machine/canning machine--to close/seal the can

(also we can connected with liquid nitrogen dosing/flushing machine to flush nitrogen inside the can,to push the Oxygen out of the can,and keep the food for longer time)

| Material | 304# Stainless steel |

| Seaming head | 1 |

| Sealing speed | 30 cans/min |

| Sealing diameter | 35-130mm |

| Sealing heigher | 50-200mm |

| Control module | Simense PLC and touch screen |

| Air sourse | 0.6-0.8MPa |

| Power | 1.3KW |

| Weight | 500KG |

| Size | 3000*900*1800mm |

| Voltage | Single phase 220V 50Hz |

(5)Double heads screw capping machine--to close the transparent/clear/cristal top screw cap

(6)Can be also connected with platic top cap capping machine instead of screw capping machine.

(7)Labeling machine--to apply sticker label on the cans/bottles/jars.

Spare parts

We have good relationship with well-known spare parts company,and gurantee the qulity of the machines.