- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2440 mm

-

Travel (Y Axis)(mm):

-

1220 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

12

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHANSHU

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

3600*2800*3500mm

-

Weight (KG):

-

4000

-

Product name:

-

Mold Making Machine

-

Application:

-

CNC Router Wood Door Making

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Spindle:

-

12kw ATC Spindle

-

Spindle power:

-

12.0kw ATC Air Cooling

-

Control system:

-

Syntec Control System

-

Function:

-

Wood Acylic Plywood MDF Engraving

-

Working area:

-

2440x1220mm

-

Motor:

-

Servo Motor

-

Inverter:

-

Best/Fuling frequency converter

Quick Details

-

Working Table Size(mm):

-

2500*1300

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.01 mm

-

Travel (X Axis)(mm):

-

2440 mm

-

Travel (Y Axis)(mm):

-

1220 mm

-

Repeatability (X/Y/Z) (mm):

-

0.01 mm

-

Spindle Motor Power(kW):

-

12

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SHANSHU

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

3600*2800*3500mm

-

Weight (KG):

-

4000

-

Product name:

-

Mold Making Machine

-

Application:

-

CNC Router Wood Door Making

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Spindle:

-

12kw ATC Spindle

-

Spindle power:

-

12.0kw ATC Air Cooling

-

Control system:

-

Syntec Control System

-

Function:

-

Wood Acylic Plywood MDF Engraving

-

Working area:

-

2440x1220mm

-

Motor:

-

Servo Motor

-

Inverter:

-

Best/Fuling frequency converter

Carving machine woodworking 3d stone and wood carving machine cnc stone engraver machine for jewelry

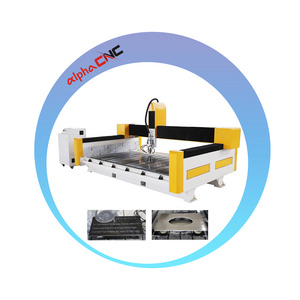

This is a 5-axis CNC router designed for engraving complex 3D workpieces. This 5-axis CNC router has the characteristics of casting integration, good rigidity, good stability, high machining accuracy, smooth operation, easy operation, powerful function and so on.

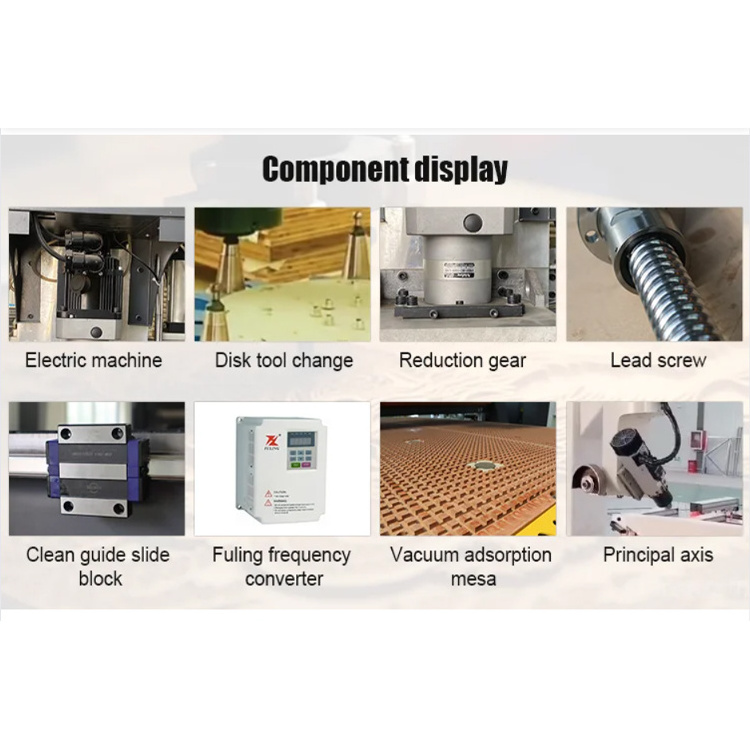

1. The table adopts PTP suction cup, which can be adjusted in size, convenient for loading and unloading, large suction, strong firmness, durable and wear-resistant, and has the advantages of long service life.

2.

Syntec

system, high precision, fast speed, simple operation and easy maintenance.

3. High-precision saw blade, multi-angle cutting, easy to quickly divide wood.

4. Dustproof guide rail, easy to install, easy to interchange, greatly reduce the driving power, high working accuracy.

|

Product name

|

5-Axis Cnc Router

|

|

Brand Name

|

SHANSHU

|

|

Working Table Size(mm)

|

2500*1300mm

|

|

Travel (Z Axis)(mm)

|

100-1000mm

|

|

Bed support

|

Welding of steel structure, tempering

|

|

Table Structure

|

Welding platform, vacuum adsorption platform (including 7.5KW high-pressure air pump)

|

|

Rail

|

Steel strip dustproof 30 high precision straight square rail(Original flange slider)

|

|

Turn-screw

|

X-axis 4020TBI high-precision grinding screw, Z-axis 4020TBI high-precision grinding screw, Y-axis 3220TBI high-precision grinding screw

|

|

Spindle power

|

12KW

|

|

Tool magazine

|

8-blade disc tool changer magazine

|

|

Five axis head

|

Yaskawa 750W+400W bus absolute value AC server

|

|

Motor drive

|

XYZ axis Yaskawa 1300w bus absolute value AC servo

|

|

Control system

|

Syntec

|

|

Auxiliary function

|

RTCP

|

Equipped with world-renowned controller, it has the advantages of powerful functions, high processing accuracy and fast speed.

Diversification control

Adopting a diversified control system to control the processing speed, idle speed and cutting speed separately, which greatly improves the quality and processing efficiency of processed products.

Multi-function 5 axis

The advanced 5 axis numerical control technology is adopted, which can realize the processing of three-dimensional, curved surface and complex parts with high precision and good efficiency.

Our products can be broadly used in wood furniture industry (wooden doors, craft window

sashes, headboards), advertising industry (acrylic panels, crystal letters, billboards)

abrasive industry (copper, iron and other metal sculpture)

Shandong Shansu Machinery Co., LTD., founded in 2009, is a diversified technology enterprise focusing on R&D, manufacturing and software development and application of automatic CNC equipment. It is a professional CNC equipment manufacturer integrating R&D, production, operation and sales. Factory location: Shandong, China.

The company focuses on creating high-endCNC equipment production research and development and non-standard customization, products cover CNC engraving equipment, plate furniture cutting equipment, CNC cutting saw series, automatic edge sealing machine series.

Our quality standard positioning is synchronized with Europe and the United States, the whole line of products with international brand parts, is a very small number of domestic CNC processing equipment processing all mechanical parts manufacturers, with advanced processing and assembly technology, and have strict process quality control, committed to providing users with long-term industrial use of stable and reliable equipment.

We are one of the few manufacturers in China that can carry out professional intelligent factory planning and provide related complete sets of equipment and software, CNC cutting equipment, automatic linear edge banding machine and high-speed CNC drilling machining center, combined with customized furniture flexible processing production line of automation software, can truly tailor-made for customers to create a package solution for the production of plate cabinets and wardrobes. Integrate customization into large-scale production.

Q: How about after-sales service?

A: 1.We can provide free training in our company. 2. If u need, our engineers are available to service machinery overseas.

Q: How about the warranty?

A: The complete machine has a one-year warranty and Life time maintenance.

Q: What should I do when I have some probleme or questione?

A: Pls don't hesitate to contact us, we will reply u ASAP.

Q: How about the quality?

A: Before we pack each machine, we will test it first. If machine has problem in your place, our worker will take responsible for his mistake. And we will solve your problem.

Q: Which is the most suitable model machine for me?

A: Pls tell us your materials, thickness, size and business industries.We will select the machine model that is right for you.

Q: Why choose us?

A:1.We have a technical team of over 50 people withyears of rich work experiences.

2.Comprehensive after-sales service.

3.quality assurance.Conducting multiplein spections and debugging after the installation of the machine, and

continuously updating the fault section.

4.We have16 yearsspecializationinCNC industry 5.We are sourcing factory with no

middle charge of the price.

Hot Searches