- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yugong/OEM

-

Power:

-

100Kw

-

Dimension(L*W*H):

-

60**20*7M

-

Weight:

-

170000

-

Product name:

-

Glove Macking Machine

-

Application:

-

Automatic Glove Maker

-

Name:

-

Latex Gloves Production Line

-

Dispoable Glove Making Machine:

-

Dispoable Glove Making Machine

-

Usage:

-

Nitrile Gloves Production Line

-

Glove Type:

-

Latex,Nitrile,NBR

-

Material:

-

Stainless Steel and Q235B

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Heating method:

-

Natural gas heating

-

Natural gas:

-

80-250m3/h

Quick Details

-

Production Capacity:

-

5000pcs/h

-

Voltage:

-

380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yugong/OEM

-

Power:

-

100Kw

-

Dimension(L*W*H):

-

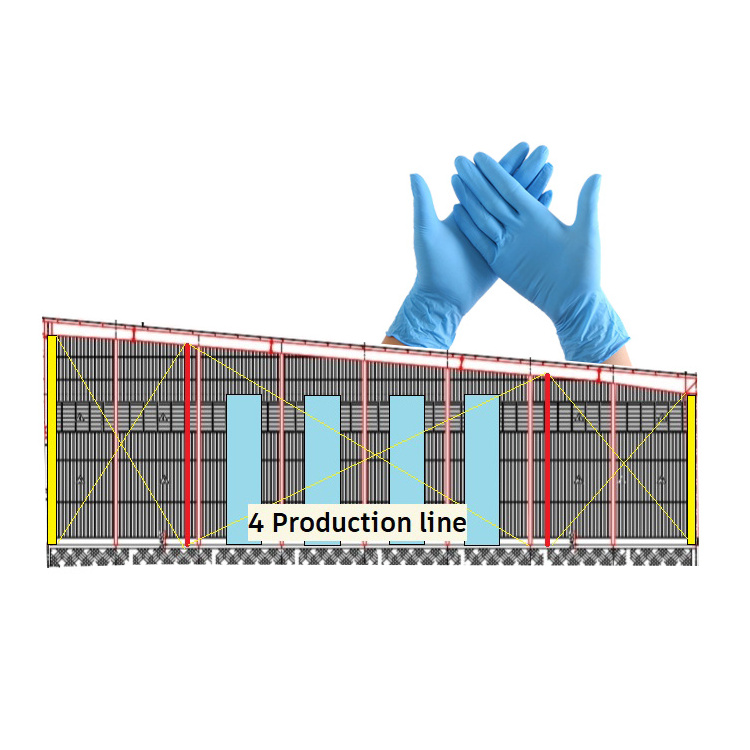

60**20*7M

-

Weight:

-

170000

-

Product name:

-

Glove Macking Machine

-

Application:

-

Automatic Glove Maker

-

Name:

-

Latex Gloves Production Line

-

Dispoable Glove Making Machine:

-

Dispoable Glove Making Machine

-

Usage:

-

Nitrile Gloves Production Line

-

Glove Type:

-

Latex,Nitrile,NBR

-

Material:

-

Stainless Steel and Q235B

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Heating method:

-

Natural gas heating

-

Natural gas:

-

80-250m3/h

Latex Glove Production Line Free Powder Nitrile Gloves High Speed Nitrile Gloves Production Line

Product Description

Glove Production Line

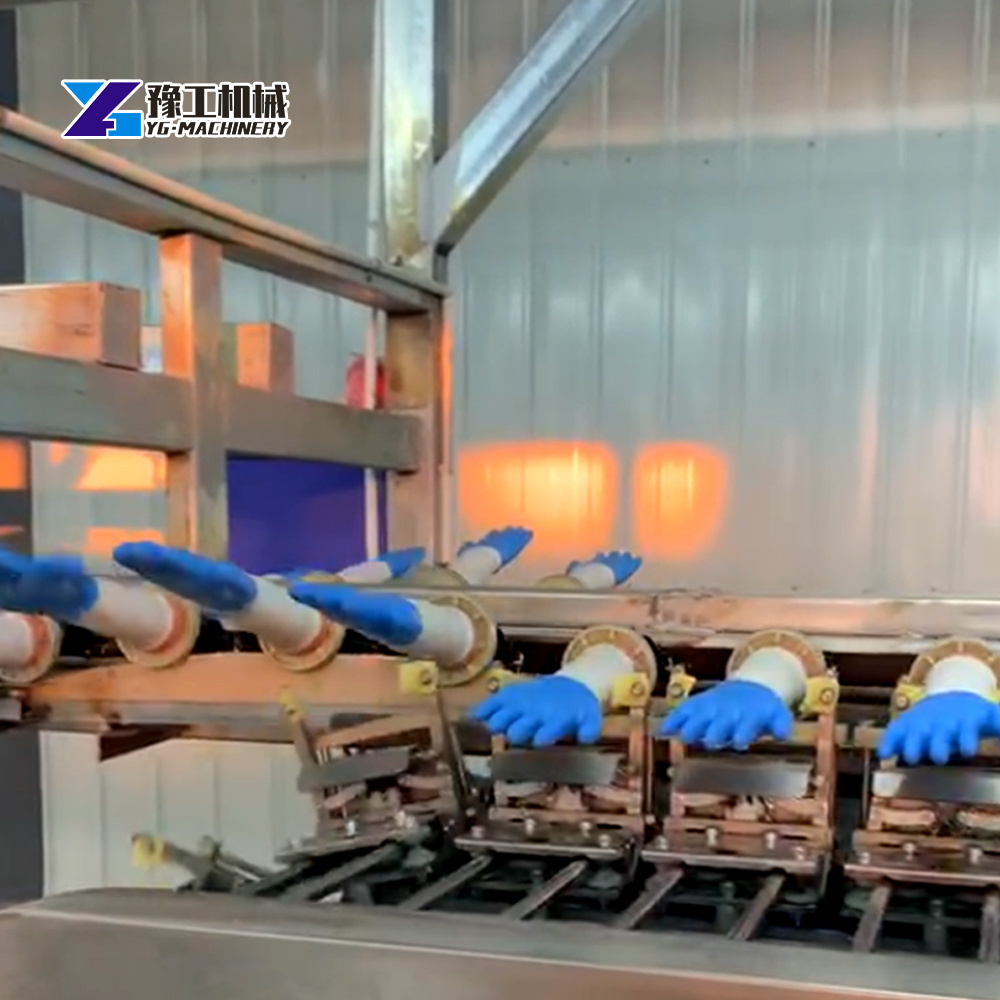

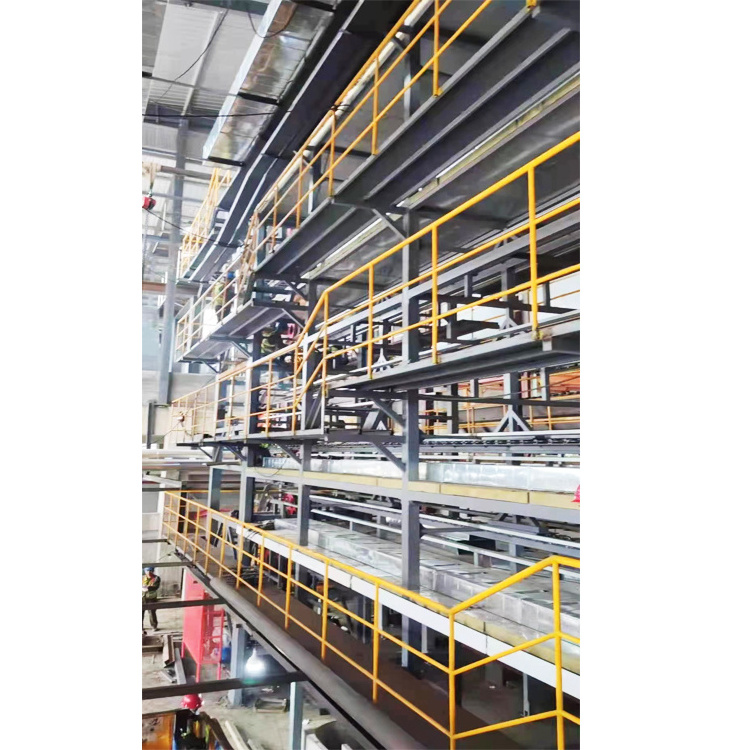

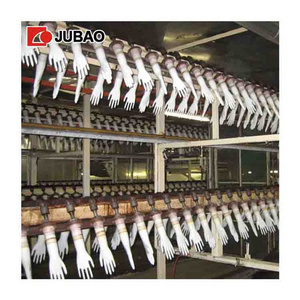

The nitrile/latex glove production line uses natural latex or synthetic rubber as the main raw material and other ma as auxiliary materials. The hand mold is cleaned, and then cleaned with water again. Then the cleaned hand mold is first immersed in hot water and heated then immersed into dried for dipping. After dipping, go into an oven for preliminary drying, flushed with hot water and then sent to another oven for curing and drying to form. After the gloves are demolded, they are inflated or filled with water for inspection, washed.centrifuged. and dried before packaging and sending them to the finished product warehouse.

Product Application

Nitrile Glove And Latex Glove

Details

Glove Making Production Line

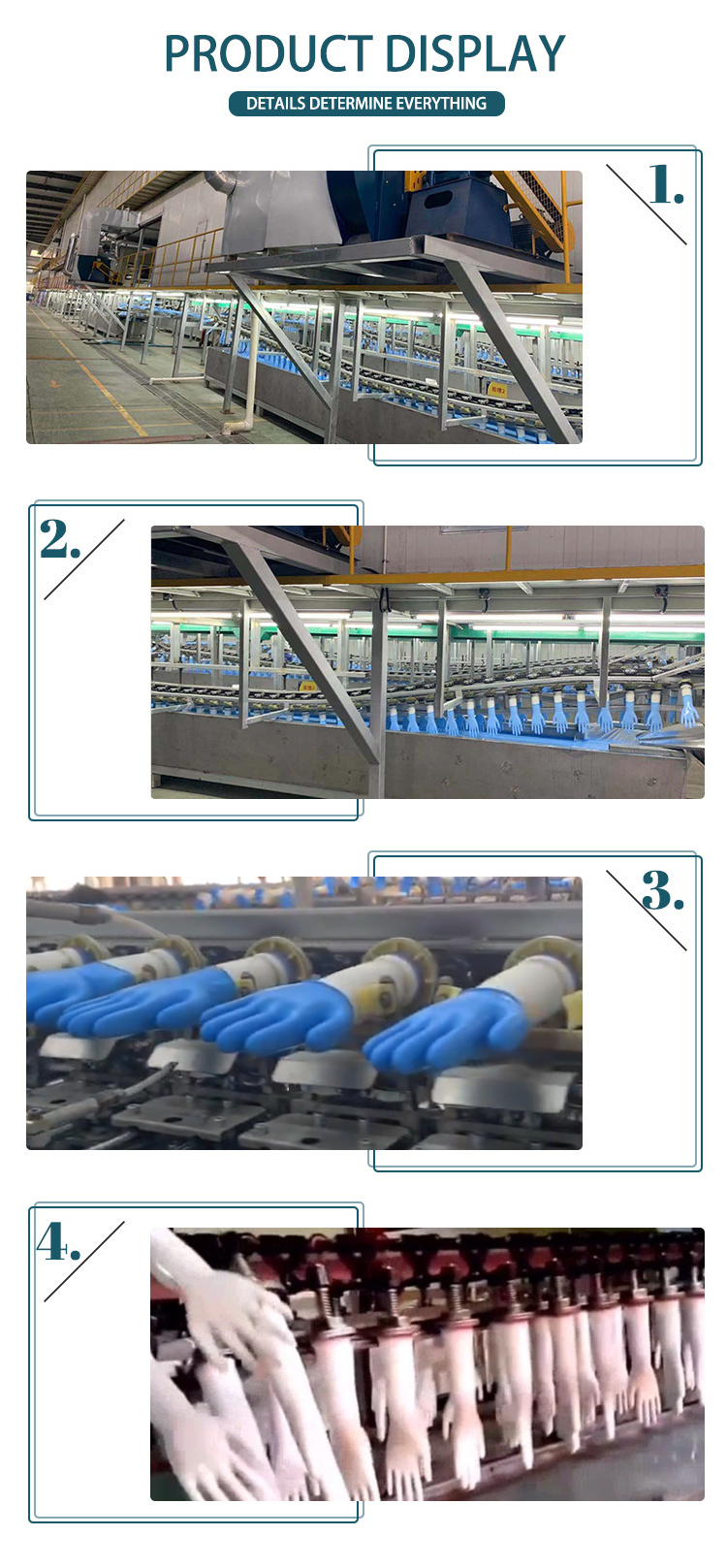

Product Display

Product Show

Installation and service

1. YUGONG COMPANY supports the client to pay by instalments.

2. All of accessories will be prepared at seller’s factory, the body of the production line can be bought from local market in order to cut client’s cost. It will take 90 days to prepare all accessories for the production line.

3. When all of parts have delivered to the client’s factory, we will arrange 2~3 engineers to guide the installation, there are of the 5-6 experienced mechanical workers from client’s side to help the installation. After finishing installation, 2 training engineers will take charge of workers’ train. The whole of process will spend 30 days on installation and train.

Packaging*Delivery

Certificate

Hot Searches