Capacity:3 tons

Coil inner diameter:450-550 mm

Feeding width: max 1000 mm

Structure: welded by the steel plates and profiled bar.

The shrink and expand of core is manually, with manual brake,The coil moving forward or reverse is pulled by roll forming machine

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220V-3P-50HZ

-

Weight:

-

4000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

New design 2023

-

Product name:

-

ridge capping tile making machine

-

Control system:

-

Delta

-

Thickness:

-

0.3-0.8 mm

-

Shaft material:

-

70 mm

-

Roller stations:

-

12 roller stations

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Color:

-

Custimized

-

Material of rollers:

-

Gcr12 Steel

-

Control box language:

-

Add Customer Request Language

-

Decoiler:

-

Manual or hydraulic decoiler

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8 mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220V-3P-50HZ

-

Weight:

-

4000 kg

-

Feeding width:

-

Other

-

Marketing Type:

-

New design 2023

-

Product name:

-

ridge capping tile making machine

-

Control system:

-

Delta

-

Thickness:

-

0.3-0.8 mm

-

Shaft material:

-

70 mm

-

Roller stations:

-

12 roller stations

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Color:

-

Custimized

-

Material of rollers:

-

Gcr12 Steel

-

Control box language:

-

Add Customer Request Language

-

Decoiler:

-

Manual or hydraulic decoiler

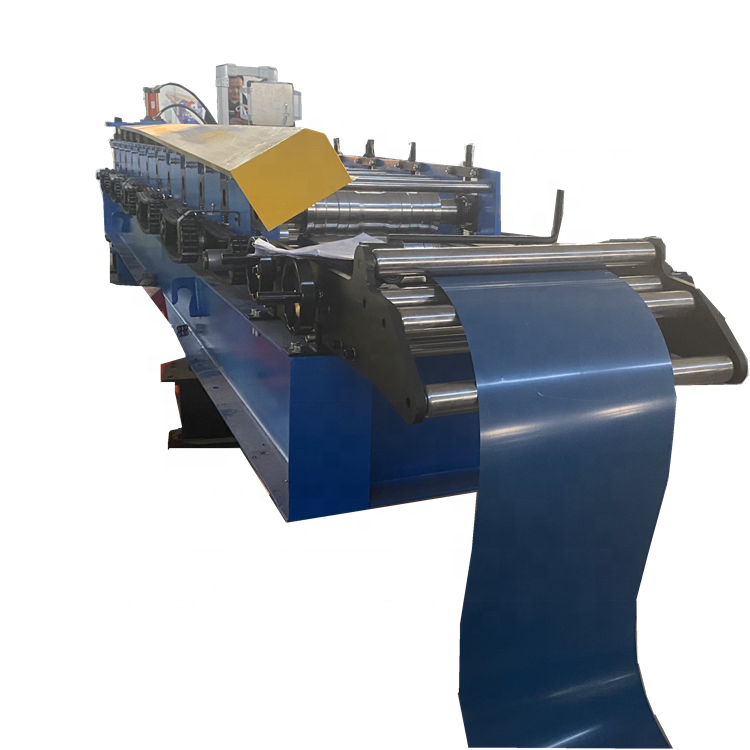

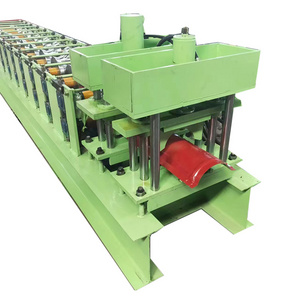

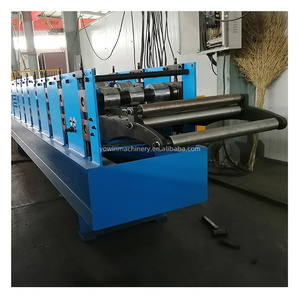

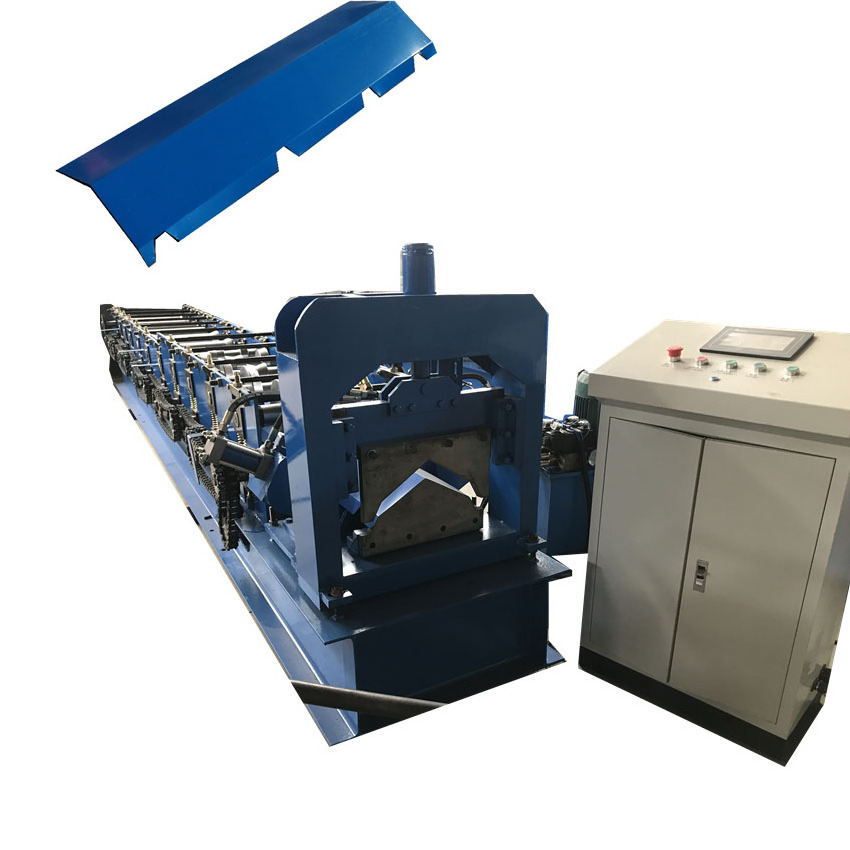

High quality Africa Kenya roofing system ridge top hat rolling forming machine

ZHONGTUO Machine introduction:

This ridge capping can match with box profile, corrugated roof sheet. Speed can reach 15 m/min with hydraulic cutting. We also can provide you other kinds of ridge capping, match with glazed tile.

Different ridge capping suit for different kind of roof sheet, here have other kinds of ridge capping for your reference.

Press step ridge capping

Suit for glazed tile.

Gap ridge capping without press step

Suit for IBR sheet and corrugated roof sheet

Gap ridge capping with press step

Suit for glazed tile or corrugated roof sheet.

Processing Flow

Uncoiling → Feeding material into machine →Roll forming

→

Hydraulic cutting →Products receiving table

|

Kenya box profile ridge capping roll forming machinery

|

|

|

|

Raw Material

|

PPGI,PPGL, GI, GL

|

|

|

Raw material

|

Material Thickness: 0.23- 0.8 mm

|

|

|

Machine Frame

|

350 mm H Beam Structure, With 18 mm Welded Steel Middle Support Plate.

|

|

|

Material Of Rollers

|

High Grade 45# Forged Steel

|

|

|

Material Of Rollers

|

Chromed Treatment (Chrome Thickness:0.05 Mm), Make The Rollers Surface More Smoothly, Improve The Hardness And Prevent Abrasion,Anti Corrosion Increase Of Service Life

|

|

|

Forming Stations

|

Roller Stations :12 Rows

|

|

|

|

Rolling Type: Separate Rolling Design Concept, It Can Release Internal Stress From The Sheets, Then The Sheet Will Be In Good Shape And High Precision.

|

|

|

Diameter Of Shafts

|

Φ70 mm Solid

|

|

|

Material Of Shafts

|

High Grade 45#,With Heat Treatment

|

|

|

Forming Speed

|

15 M/MIN

|

|

|

Voltage

|

380v/50hz/3p (As Requested)

|

|

|

Transmission Way

|

By 1 Inch Chain (Double Chains)

|

|

|

Main Motor

|

4 kw

|

|

|

Cutting Blade Material

|

Gcr12 quenched treatment

|

|

|

Cutting Type

|

hydraulic post cutting

|

|

|

Driving Method

|

By pillar type Cylinder

|

|

Profile drawing for reference:

Here are some similar ridge capping design for your reference, you can choose from them. The width and height a little different.

Finished product effect for your reference

Below ridge capping produced by our machine, please check the roll forming effect. After test machine, we will measure the dimension and ensure it's dimension same as profile drawing.

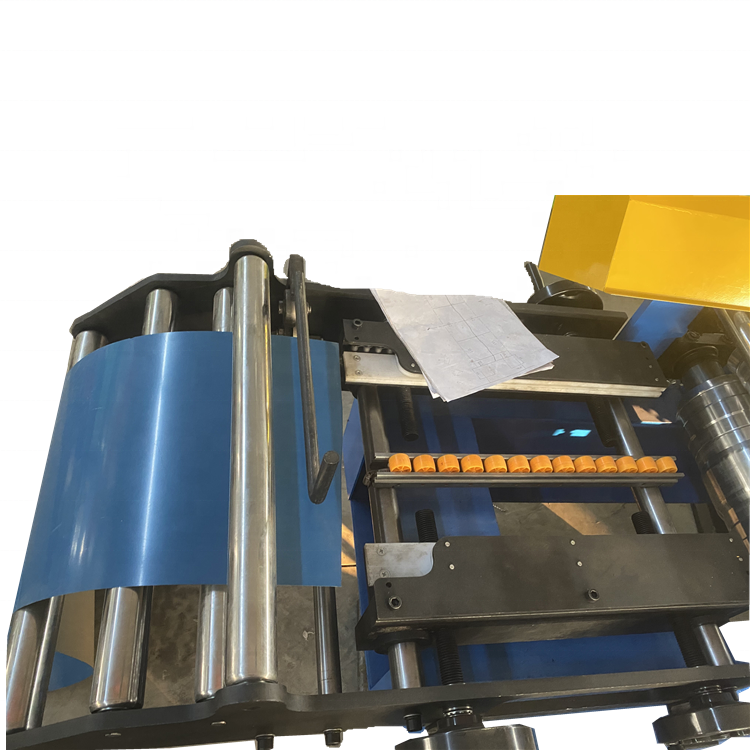

3T Manual Decolier For Free

Feeding Device

1.Hand wheels on both sides can be used to adjust the feeding width.

2.Touch stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3.There are three rows of orange plastic rubber rollers can make the steel coil go into the machine smoothly.

Hydraulic Cutting Device

Cutting type is hydraulic cutting, cutter material is Cr12.

PLC control system

Hydraulic station

● Hydraulic station motor: 4 KW

● Hydraulic oil:46# hydraulic oil

● Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve

CE(

NO.OP180719.CZIDC95

)

ISO 9001(No:ZL92090220234630)

Hot Searches