- Product Details

- {{item.text}}

Quick Details

-

Liquid Flow Rate:

-

plz contact

-

Maximum Working Pressure:

-

plz contact

Quick Details

-

Structure:

-

Plate Heat Exchanger

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AIRTECH/API HEAT TRANSFER

-

Liquid Flow Rate:

-

plz contact

-

Maximum Working Pressure:

-

plz contact

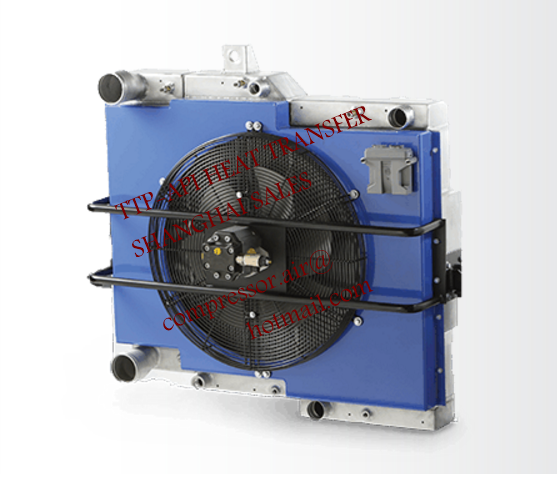

S-BAR, T-BAR, P-BAR Modules-TTP Engine Cooling Modules / API HEAT TRANSFER-COVRAD

TTP Engine Cooling Modules

API Heat Transfer offers Thermal Transfer Products manufactured custom OE engine cooling modules for small gasoline engines to large-horsepower turbo diesel applications. Your choice of a variety of materials and core types (S-BAR, T-BAR, or P-BAR) offers design flexibility for high-performing radiators, CAC’s, or oil cooling. Full system modeling and validation of cooling modules is provided.

Core types

EXTRUDED TUBULAR BAR | RUGGED & REFINED

T-BAR™ (tubular micro-channel extrusion) brings you the most refined cooling technology on the market today.

- Engineered with minimal components in an ideally simplified configuration

- Unrivaled strength and rigidity to ensure durable performance

- A flexible design using an extruded flow path

- A high-performing, cost-effective domestic aluminum solution

PLATE & BAR | HIGH VOLUME & LOW VARIETY APPLICATIONS

P-BAR™ (custom plate & bar) is your best heat-transfer solution for higher volume (qty.) applications, and when competitive costs are key.

- Custom-engineered engine cooling with remarkable heat rejection

- High performance for mobile or industrial applications

- A flexible design

- A cost-effective LCC aluminum solution

SEAM WELDED TUBE | RUGGED & REFINED

S-BAR™ is the most affordable, high-flow cooling technology on the market today.

- A high-strength automotive style core design

- Durable, multi-row tube to header plate design

- Engineered for use in applications with higher temperatures and heat loads

- A lightweight, reliable and cost-effective aluminum solution

Schmidt ® SIGMA Gasketed Plate Heat Exchangers

Plate heat exchangers use corrugated plates stacked between a fixed and movable pressure plate. As virtually all of the material is used for heat transfer, plate heat exchangers can have large amounts of effective heat transfer surface in a small footprint. It is not uncommon that a plate heat exchanger will have the same thermal capacity as a shell and tube five times larger. Our plate heat exchangers incorporate superior design features to ensure long-term performance and customer satisfaction.

PERFORMANCE NOTES.

- Unique corrugation pattern pressed onto each plate produces the highest overall heat transfer rate by assuring turbulent flow and excellent fluid distribution across the entire surface

- True counter current flow and high heat transfer rate allows our plate heat exchangers to economically handle close temperature approach requirements

- Highest quality gaskets precisely fit the plate grooves for positive sealing and ease of maintenance

- Superior clip-on gasket design ensures proper fit during closing of the unit

- Double sealing design prevents the possibility of mixing the two process fluids; leak detect feature ensures any leakage is to the atmosphere

- Zinc coated hardware provides long life

- All bolted construction for easier service

- Low volumetric fluid hold-up provides quicker response to heating and cooling demands, while reducing costs for more expensive process fluids

- Readily expanded for greater capacities, or totally new applications

- Available in a variety of plate sizes for industrial, HVAC, power, or food industry applications

OPERATING PARAMETERS.

TECHNICAL PARAMETERS.

| Frame | Painted carbon steel, or stainless steel (solid and clad) |

| Connections | |

| Standard | Studded with option for liner, flanges (ANSI, DIN), food stuff connections |

| Exotics | Ti, SMO, hastelloy, and 904L, others available |

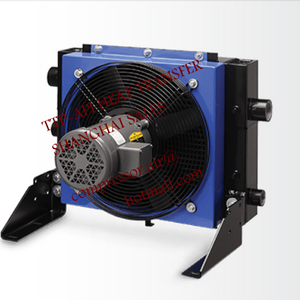

Engine Cooling Systems

API Heat Transfer is your global source for engine cooling solutions. We’re equipped to offer unparalleled engine cooling performance to meet the rigorous requirements of mobile and industrial customers worldwide.

We offer an array of internal and external fin configurations that produce some of the most efficient air-cooled heat exchange cores in the industry, so your engine has more power to perform, even under the harshest conditions.

We focus our engineering expertise on the markets you serve. By understanding your customer applications, we’re able to offer a broad spectrum of components and complete engine cooling systems designed to fit the needs of engine markets across the world.

OUR TECHNOLOGIES.

API Heat Transfer offers the broadest, most complete air-cooled product lines available.

- CAB or vacuum-brazed aluminum

- Bar-plate

- Micro-channel

- Tube and header

- TBAR

- Copper-brass

- Mechanical-bond

- Soldered

- Bolted tank

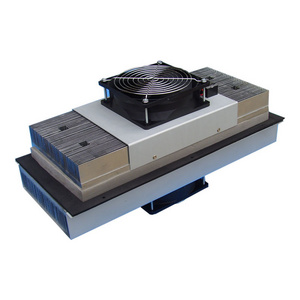

Frac Pumper Cube Cooling Module

API Heat Transfer now offers a line of frac pumper cooling modules in a cube configuration for applications that require a lighter, more compact cooling package than our standard horizontal units.

These modules are made with aluminum heat exchanger technology and feature critical design enhancements that greatly improve maintenance, including a large cab-side access door for on-site cleaning.

TURNKEY COOLING SOLUTIONS.

- 20% lighter in weight than traditional horizontal units

- All-aluminum cooling modules

- Laser-cut, high-strength steel framework

- Custom designed cab-side door for easy access maintenance

- Plumbing of ancillary coolers to internal bulkhead

- Available in both three-point and four-point mounting options

- Complete standard black powder coat of all steel, with custom colors available

- Improved design for ease of cleaning the heat exchanger cores from the outside or inside

Brazed Aluminum Charge Air Coolers

Engine manufacturers and OEMs worldwide rely on our robust and reliable charge air cooler technology and expertise to meet ever changing emissions regulations. We’ve specially selected fin and tube options to provide the performance and durability the application calls for.

BAR AND PLATE CHARGE AIR COOLERS

Flexible bar and plate construction allows an infinite number of core configurations and sizes to custom design a solution specifically to your exact requirements with minimal or no tooling costs.

- Enhanced internal fin geometries for superior cooling

- Highly flexible design

- Wide variety of hot fins to balance internal pressure drop

- High-efficiency louvered fins for superior heat rejection

- Wide variety of debris resistant non-louvered fins

- Welded on tanks for a long leak-free life

- Rugged construction for heavy duty applications

TBAR CHARGE AIR COOLERS

Our patented TBAR replaces hot fins and bars with a single extruded tube for increased product durability.

- Highly flexible design

- Enhanced extruded tubes for improved charge air cooling

- Patented tube-to-bar joint ensures consistent brazing

- Extruded tubes provide unrivaled durability & fewer leak paths

- High-efficiency louvered fins for enhanced heat rejection

- Wide variety of debris resistant non-louvered fins

- Welded tank to core for a long leak-free service life

- Zinc-Infused aluminum materials for unrivaled corrosion protection

- Low charge-air side pressure drop

- Stands up to heavy thermal cycle loads

Aluminum Radiators

API Heat Transfer offers a wide range of brazed aluminum radiator styles and options. From small individual coolers to large complex engine cooling systems, from heavy duty bar and plate construction to plastic tank radiators, we have the right design for your mobile or industrial application. Our engineering team is continually developing additional fin geometries to improve heat transfer efficiency so we can meet or exceed your expectations.

BRAZED BAR AND PLATE RADIATORS

Fins are laid between aluminum braze sheets and fitted with header and face bars. The assembled unit is placed into one of our modern brazing furnaces where precise control of time and temperature produces a unified core. Manifolds designed to meet each customer's particular piping requirements are welded into place to complete the radiator.

- Ideal for heavy duty mobile and industrial applications

- Feature a wide variety of thermally efficient internal and external fin patterns

- Rugged, compact, lightweight units

- Infinite number of core configurations and sizes to custom design a solution specifically to your exact requirements

- Combi-cooler designs are available to cool multiple fluids in a single brazed unit

- Available as component cooler or packaged as a complete cooling system incorporating radiator and/or charge air cooler with oil cooler components

TBAR RADIATORS

Our patented TBAR replaces hot fins and bars with a single extruded tube for increased product durability.

- Highly flexible design

- Enhanced extruded tubes for improved charge air cooling

- Patented tube-to-bar joint ensures consistent brazing

- Extruded tubes provide unrivaled durability and fewer leak paths

- High-efficiency louvered fins for enhanced heat rejection

- Wide variety of debris resistant non-louvered fins

- Welded tank to core for a long leak-free service life

- Zinc-infused aluminum materials for unrivaled corrosion protection

- Low charge-air side pressure drop

- Stands up to heavy thermal cycle loads

TUBE AND HEADER RADIATORS

Our brazed aluminum tube and header radiators offer a cost effective, lightweight solution for stationary and mobile engine cooling applications. Radiators can be provided as a stand alone component, but most often would be combined with our bar and plate oil coolers and charge air cooler to form a complete engine cooling solution.

- Wide range of row depths

- Variety of external fins to match different environmental conditions

- Tanks designed to meet piping requirements and are welded into place for superior integrity

- Welded aluminum tanks can be fabricated, stamped or cast depending on application and volume

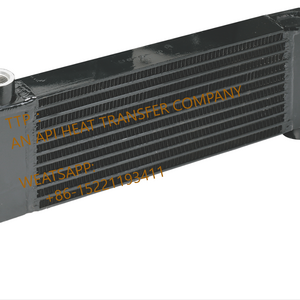

Bar and Plate Heat Exchangers

API Heat Transfer's line of Airtech and Covrad air cooled all-aluminum brazed bar and plate heat exchangers are supplied as a vital component to our mobile and industrial OEMs' products. Our flexible bar and plate construction allows countless core combinations and sizes, custom designed to your exact requirements with minimal or no tooling costs. Combi-cooler designs are available to cool multiple fluids in a single brazed unit.

PRODUCT TYPES AVAILABLE.

- Engine cooling systems

- PCR (pre-cooler, cooler, reheater) for refrigerated air dryers

- Charge air coolers

- Radiators

- Oil coolers

- Aftercoolers

- Combination coolers

Our bar and plate coolers feature a wide variety of thermally efficient internal and external fin patterns. Fins are laid between aluminum braze sheets and fitted with header and face bars. The assembled unit is placed into one of our modern brazing furnaces where precise control of time and temperature produces a unified core. Manifolds designed to meet each customer's particular piping requirements are welded into place to complete the cooler. We can also supply cores when manifolds already exist or must be fitted in the field.

These rugged, compact, light-weight units are ideal for both on- and off- highway markets. API Heat Transfer can also add value beyond the component cooler by packaging a complete cooling system consisting of multiple coolers (e.g., radiator, charge air cooler, hydraulic oil cooler).

From small individual coolers to large complex engine cooling systems, API Heat Transfer will design and manufacture the heat transfer solution that's right for you. Our engineering team is continually developing additional fin geometries to improve heat transfer efficiency so we can meet or exceed your expectations.

Our products perform-AIRTECH

Whether you're looking for a custom heat transfer solution (our specialty) or a more standard product, you’ll find what you need right here. That's because we offer the broadest range of heat transfer products available. And if you don’t find the solution you’re looking for, let's talk so our team of experts can create it.

Engine Cooling Systems

API Heat Transfer is your global source for engine cooling solutions. We’re equipped to offer unparalleled engine cooling performance to meet the rigorous requirements of mobile and industrial customers worldwide.

We offer an array of internal and external fin configurations that produce some of the most efficient air-cooled heat exchange cores in the industry, so your engine has more power to perform, even under the harshest conditions.

We focus our engineering expertise on the markets you serve. By understanding your customer applications, we’re able to offer a broad spectrum of components and complete engine cooling systems designed to fit the needs of engine markets across the world.

OUR TECHNOLOGIES.

API Heat Transfer offers the broadest, most complete air-cooled product lines available.

- CAB or vacuum-brazed aluminum

- Bar-plate

- Micro-channel

- Tube and header

- TBAR

- Copper-brass

- Mechanical-bond

- Soldered

- Bolted tank

API heat transfer

Five brands.

One answer for heat transfer.

With a legacy of innovation dating back to 1879, our brands are known the world over as leaders in their respective fields. They provide our customers with the technologies and product portfolio needed to handle any heat transfer project. From custom to pre-engineered designs, API Heat Transfer offers comprehensive solutions – all from one company.

Airtech:

Industrial air cooled heat exchangers

Airtech heat exchangers are available in bar and plate, tube and header, and micro-channel constructions. Airtech coolers offer unparalleled performance in a rugged yet compact and lightweight package for industrial applications.

Basco:

Shell and tube heat exchangers

Basco heat exchangers include a full range of custom-engineered and commercial standards. Available in a wide variety of materials, custom solutions are made to meet the most stringent specifications as well as all international pressure codes. Designs include TEMA types, extended surface, hairpins, surface condensers, and a full line of on-engine water-cooled charge-air-coolers and heat exchangers.

Covrad:

Engine cooling systems

Established in 1884, Covrad products employ the latest aluminum and copper-brass air cooled technologies to produce custom engine cooling systems for the full range of diesel-powered equipment.

Schmidt:

Plate heat exchangers and thermal systems

Introduced in 1879, Schmidt plate heat exchangers include industry-leading gasketed (special and standard gaskets), all-welded, semi-welded, double-wall, and brazed products for most industrial markets.

Thermal process systems include evaporation systems, dealcoholization plants, and pasteurizers used for thermal treatment of various liquids in all industries.

TTP:

Heat exchangers sold through distribution

TTP offers a complete portfolio of pre-engineered products available from API Heat Transfer, sold through a global network of distribution partners . This includes a broad range of fluid power related heat exchangers (oil-water, oil-air, air-air) utilized in mobile and industrial applications, along with custom engine cooling modules.