Round vibration machinery is a professional manufacturer of ultrasonic vibrating screen, according to the specific needs of customers to customize the design and production of equipment.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220/380

-

Weight:

-

300 KG

-

Size:

-

Base on needs

-

Layer(s):

-

1-5 Layers

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YUANZHEN

-

Voltage:

-

220/380

-

Weight:

-

300 KG

-

Size:

-

Base on needs

-

Layer(s):

-

1-5 Layers

Products Description

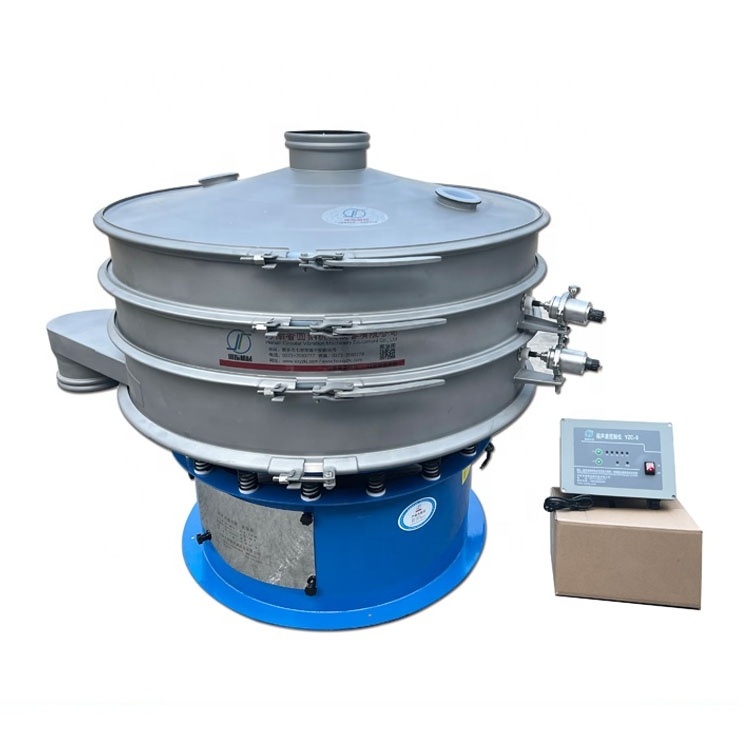

Fine powder special sieve

- ultrasonic vibrating screen

Ultrasonic vibrating screen, also known as ultrasonic vibrating screen, ultrasonic rotary vibrating screen, high efficiency vibrating screen, circular ultrasonic vibrating screen. It is our company based on years of experience in fine screening and classification, developed with independent intellectual property rights of ultrasonic vibrating sieving machine, mainly used to sieve ultra-fine powder materials.

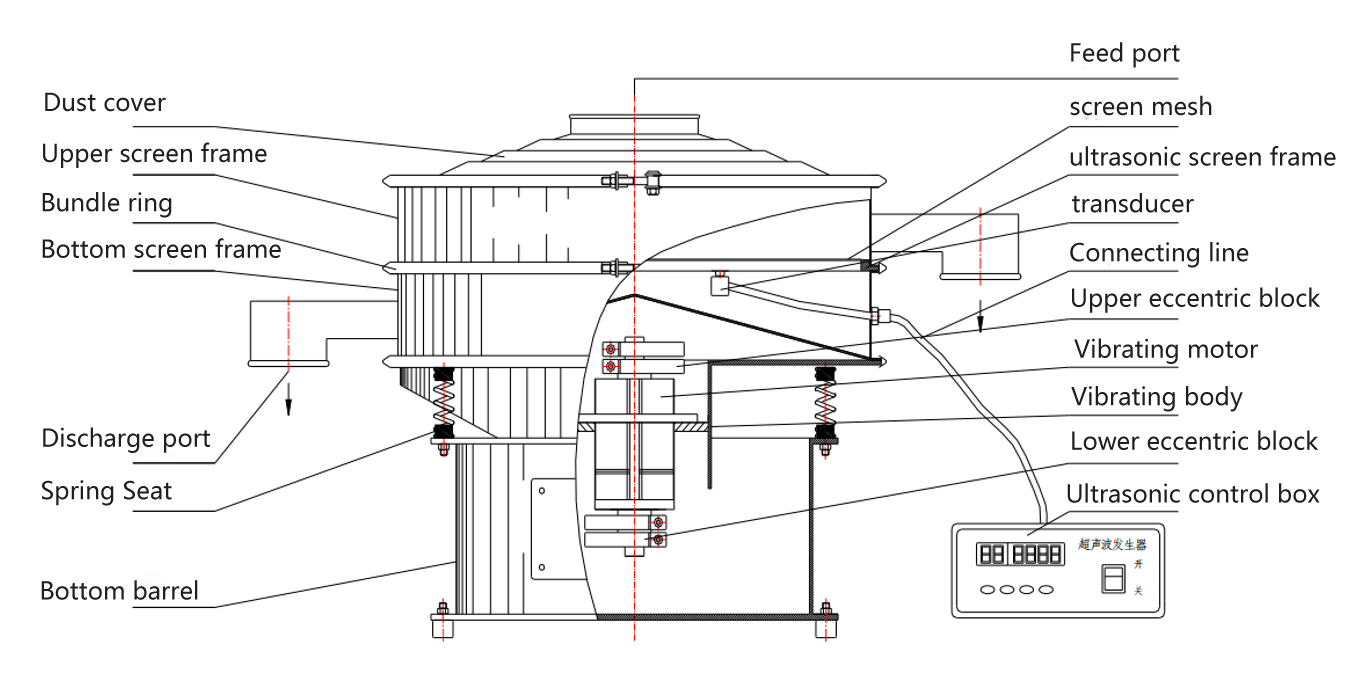

Structural principle

Ultrasonic vibrating screen converts 220V, 50Hz or 110V, 60Hz electrical energy into 18KHz high-frequency electrical energy, which is input into an ultrasonic transducer to turn it into 18KHz mechanical vibration, so as to achieve the purpose of sieving and cleaning the screen, making the ultra-fine powder sieve Separation becomes an easy task, especially suitable for users with high added value and fine separation, and can be widely used in test sieves and working sieves.

Product Features

1. In addition to the three-dimensional vibration, the mesh surface produces superimposed ultrasonic resonance.

2. There is no mesh clogging, a thorough self-cleaning function of the screen, and no degradation of screening efficiency.

3. Do not use bouncing balls and other auxiliary cleaning devices to prevent debris from polluting materials.

4. Keep the mesh size, the screening accuracy can be as high as 625 mesh, and the screening efficiency can be increased by 1-70% compared with ordinary rotary vibrating screens.

5. Decompose the adherent substances and reduce the sieve.

6. Power 18K-40K can be converted to high frequency at low frequency according to the specific gravity of the material.

7. The transducer can work continuously for 12-24 hours.

8. Reduce the number of screenings.

Common Model

|

Model

|

YZC-400

|

YZC-600

|

YZC-800

|

YZC-1000

|

YZC-1200

|

YZC-1500

|

||||||

|

Nominal diameter(mm)

|

Φ350

|

Φ550

|

Φ750

|

Φ950

|

Φ1150

|

Φ1430

|

||||||

|

Effective screening area(m

2

)

|

0.0804

|

0.2124

|

0.4072

|

0.6221

|

0.9331

|

1.5175

|

||||||

|

Power(Kw)

|

0.18

|

0.37/0.55

|

0.55/0.75

|

0.75/1.5

|

1.1/1.75

|

1.75/2.2

|

||||||

|

Support customized production(

Click here to get accurate quotation

)

|

|

|

|

|

|

|

||||||

How to select the right type?

Attention:

The selection of screening equipment and your use of demand has a lot to do with the following information you need to provide.

Ⅰ.If you have ever used the screen machine

Kindly please tell us its

DIAMETER,LAYERS,MESH SIZES,MATERIALS.

Ⅱ. If never use the machine until now

Please offer us the info about material as below:

1.

the name of the material.

2.

Material characteristics (e.g. specific gravity, bulk density, water content, fluidity, adhesion, electrostatic properties, etc.)

3.

the purpose of use (sieving / debris / liquid filtration / media separation)

4.

How many layers do you need? Mesh size of each layer?

5.

expected processing capacity per hour (Kg/h)

In this way,we can precisely choose the matching model for you to meet your use requirements.

6.

Voltage(V),Frequency(Hz),Phase(P)

---------------------------------------------------------------------------------------------------------

In order to make it more convenient for you, you can compare the following table to clear your machine configuration

(

You can also click this link to contact us directly)

|

General requirements

|

Diameter Size(mm)

|

400/800/1000/1200/1500/2000

|

|

|

||

|

|

Number of Layers(L)

|

1-5(Suggest ≤ 3)

|

|

|

||

|

|

Main Material

|

Stainless Steel(304/316L)·Carbon Steel(Q235)·PP

|

|

|

||

|

|

Screen Mesh Number

|

100-635

|

|

|

||

|

|

Transducer Installation Method

|

Built-in / External

|

|

|

||

|

|

Sealing Strip

|

Silica gel / Rubber

|

|

|

||

|

Special requirements

|

Overall height of the fuselage

|

Please communicate specifically

|

|

|

||

|

|

Feed inlet

|

Angle / Size and so on

|

|

|

||

|

|

Outlet

|

Angle / Size /Add valve

|

|

|

||

|

|

Observation port

|

Silicone cover / Rubber cover / Glass cover

|

|

|

||

|

|

spring

|

You can choose whether to add a silicone protective cover

|

|

|

||

|

|

Internal spray(mm)

|

PTFE / ePTFE / WC / Al

2

O

3

|

|

|

||

|

|

Equipment surface treatment

|

Polishing / Sandblasting

|

|

|

||

|

|

Body metal material requirements

|

For example: require no Cu and Zn (except electrical parts)

|

|

|

||

|

|

Vibration motor

|

Ordinary motor / Explosion-proof motor

|

|

|

||

|

|

other

|

Please click here to contact us

|

|

|

||

Show Details

Discharge port

The discharge port can be added with a flow valve according to your needs to control the residence time of the material on the screen.

view port

The observation port can be made of silica gel, rubber and

observation mirror

according to your needs.

Clamp ring

This structure can help you save time for fastening and disassembly.

Ultrasound system

The ultrasonic system can adjust the power according to your needs to achieve a better screening effect.

Welding technology

Sophisticated welding process is the guarantee of quality.

Spray

PTFE, ePTFE, WC and

Al

2

O

3

can be sprayed according to your needs.

Product Show

We provide you with quality products and services.

---------------------------------------------------------------------------------------------------------

Please click on the pictures below to learn about related products

Application

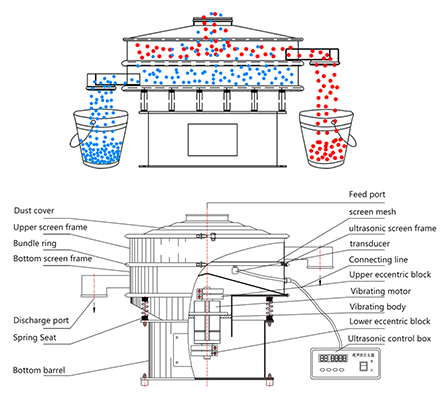

We used ordinary vibrating screen and ultrasonic vibrating screen for comparison, the following is the reference result.

If you have further questions, please click here to contact us.

|

Test Materials

|

|

Test results

|

|

|

|

|

|

General sieving equipment

|

Ultrasonic vibrating screen

|

|

|

S

i

C

|

500

|

Unable to sieve

|

1500KG/H

|

|

|

Tungsten carbide powder

|

600

|

No fine powder is sifted out in 15 minutes

|

30KG/H

|

|

|

Vitamin C powder

|

100

|

1KG/H

|

120-150KG/H

|

|

|

pollen

|

400

|

No fine powder is sifted out in 15 minutes

|

15 minutes to sieve out 20% fine powder

|

|

|

Nickel powder, cobalt powder

|

400

|

Sieve three times to meet the requirements

|

Sieve once to meet the requirements

|

|

|

NdFeB powder

|

300

|

32.2% sieve residue at 30 min

|

6.9% sieve residue at 30 min

|

|

Application Scenario Description

Ultrasonic vibrating screen can be used for impurity removal, classification and filtration of ultra-fine powder materials in various industries, and the screening accuracy can be as high as 635 mesh.

Common screening materials are:

metallurgical powder, electromagnetic material, metal powder, electrode powder, iron powder, zinc oxide, aluminum oxide powder, alloy powder, molybdenum powder, cobalt powder, emery, copper powder, nickel powder, silicon powder, oxide Titanium, tungsten carbide, tungsten powder, titanium powder, stainless steel powder, abrasive silicon carbide powder, battery materials, etc.

Customer Case

Why Choose Us

About Yuanzhen

Henan Yuanzhen Machinery Equipment Co., Ltd. is an enterprise integrating production, technology research and development, and trade. Our main products are screening equipment and conveying equipment, and we can also provide design, production and installation of other related equipment.

Yuanzhen’s sales network has penetrated the whole China, and many products have gone to the world through other foreign trade companies. Now it is necessary to build a more complete sales network so that users in more countries can use our products and feel our dedicated service.

Yuanzhen sincerely treat every customer, hope to make friends with people from all over the world, and very looking forward to establishing a long-term win-win partnership with you.

Our Team & Service

Basis service

1.Your sample material can be free analysis in our laboratory.

2.24 hours a week online & quick response within 12 hours.

3.Production lead time and delivery time guaranteed.

Customized services

1.Professional R & D team to develop the new products as you requirements.

2.Help customers to develop the local market

3.All packing and shipping can customized as per your requirements.

After-sale services

After customers received the goods,if have any questions or quality problems, Our customer service Dept. will

be always available.

be always available.

Packaging & Shipping

---------------------------------------------------------------------------------------------------------

All packing and shipping can customized as per your requirements.

FAQ

Q:What is the quality of the product?

A:We have complete quality control system. We have team leader, section leader and quality control manager to control the quality by each step. Welcome to our factory for cooperation!

Q:What factors I need to get a quotation?

A: Name & bulk density of materials;Capacity per hour;Mesh size and decks;Material of the machine;Voltage Frequency(Hz).

Q:How about price?

A:We are a factory, we provide you with quality and reliable products while giving you better prices, "high cost performance" - that's what we are.

Q:What is the real delivery time of your factory?

A: 7 to 15 days for general series products, meanwhile, batches products & customized products would need 30 days to 60 days based on different situations.

Q: How do your after-sale service work if the product got damaged?

A: In the guarantee time 12 months, our general after-sale service is changing the damaged parts for the customer, but if the damage could be repaired by slight cost, we would wait for the customer's bill for the fix cost and refound this part of cost.(note: Vulnerable parts do not include.)

Q:Service and Payment Terms?

A:We usually accept T/T, L/C;

T/T: 30% in advance as down payment, the balance before delivery;

We take pictures of finished products before delivery.

---------------------------------------------------------------------------------------------------------

If you need accessories, please click on the picture below to enter

Still can't meet your needs?

Please click here to contact us.

Hot Searches