- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

GOLD

-

Model Number:

-

GD-H1358

-

Product name:

-

Shear Stability of Polymer Containing Fluids Tester

-

Applicable standard:

-

ASTM D6278, SH/T0103

-

Timing method:

-

Digital timer

-

Counting method:

-

Automatic stroke counter

-

Refrigeration method:

-

Compressor refrigeration

-

Temperature control range:

-

35±0.2

-

Circulation mode:

-

Magnetic pump circulation

-

Flow rate control:

-

Liquid flow meter

-

Pressure control:

-

Pressure transmitter, digital display

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

GOLD

-

Model Number:

-

GD-H1358

-

Product name:

-

Shear Stability of Polymer Containing Fluids Tester

-

Applicable standard:

-

ASTM D6278, SH/T0103

-

Timing method:

-

Digital timer

-

Counting method:

-

Automatic stroke counter

-

Refrigeration method:

-

Compressor refrigeration

-

Temperature control range:

-

35±0.2

-

Circulation mode:

-

Magnetic pump circulation

-

Flow rate control:

-

Liquid flow meter

-

Pressure control:

-

Pressure transmitter, digital display

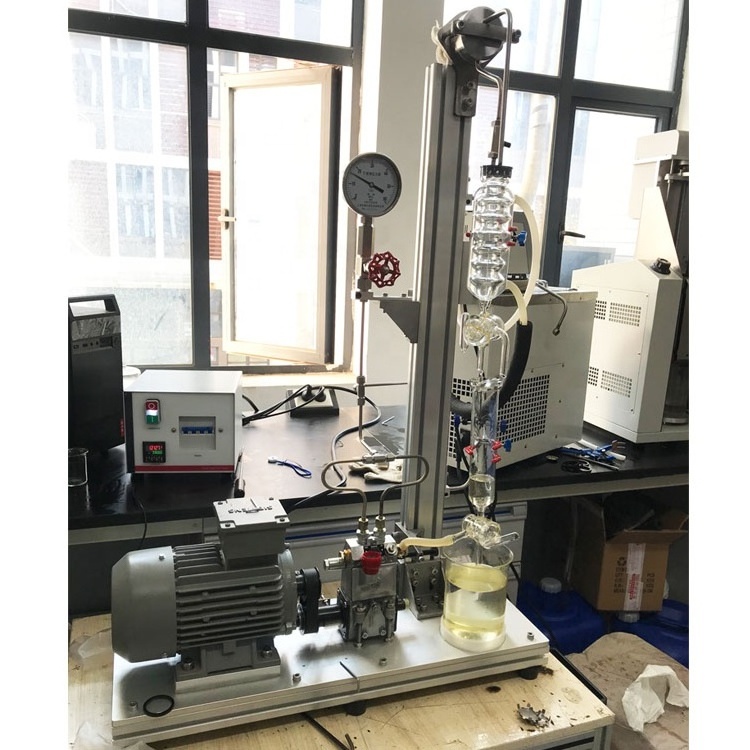

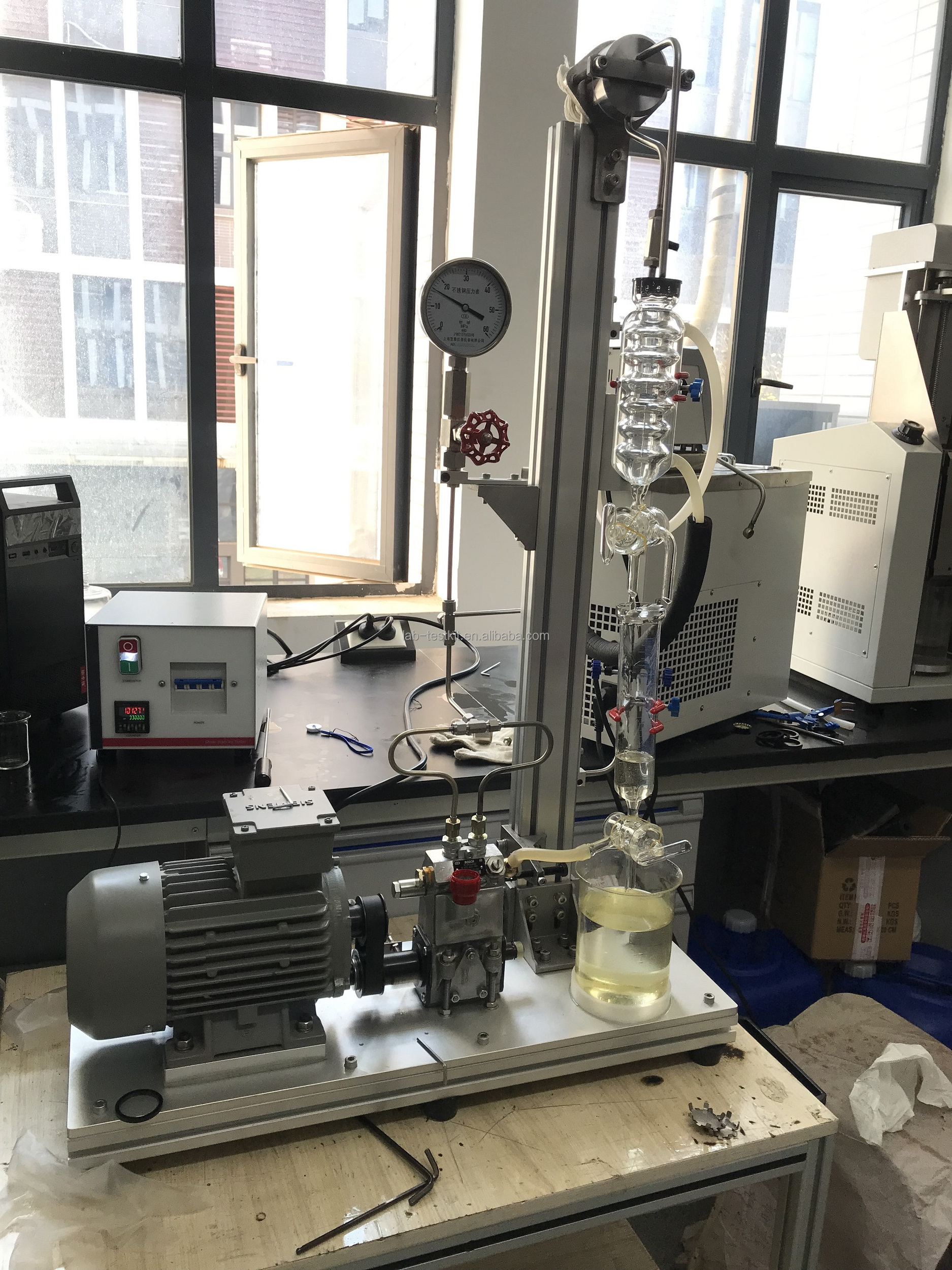

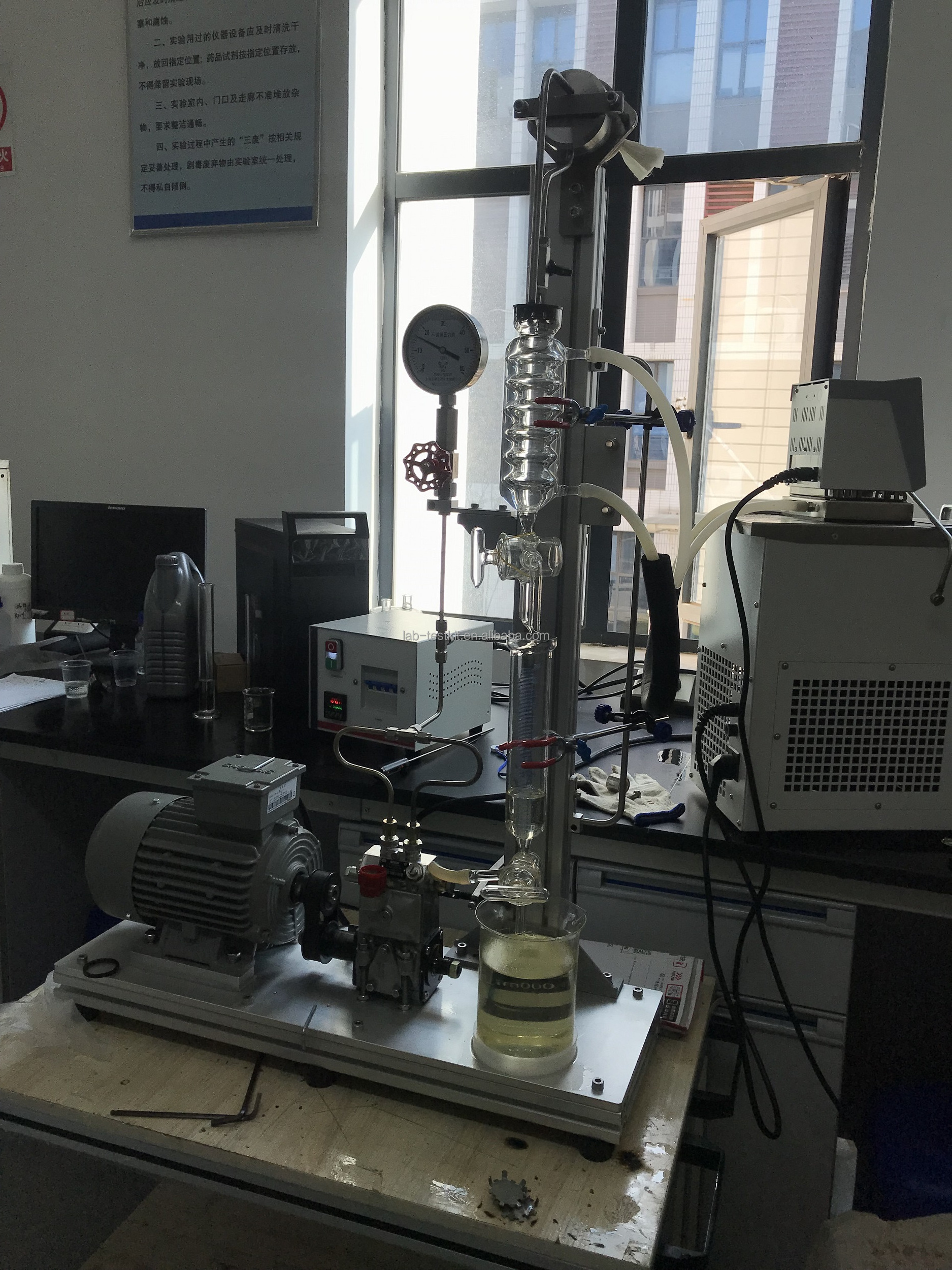

ASTM D6278 Shear Stability Tester of Polymer Containing Fluids by Diesel Injector Nozzle Apparatus

Test Standards:

ASTM D6278, SH/T0103

Product structure:

The apparatus consists of motor, coupler, gears, oxygen bomb tray, oxygen bomb, heater, temperature controller, touched LCD screen and pressure transmitter.

Application:

1.Analysis of hydraulic and gear oils used in mining and construction equipment.

2.Screening of polymers used as viscosity index improves in oils.

3.Development of predictive models using both friction torque and kinematic viscosity loss of oils.

4.Investigate accelerated oil aging in the lab (Blog)

Significance and Use:

1.This test method covers the evaluation of the shear stability of polymer-containing fluids. The test method measures the percent viscosity loss at 100°C of polymer-containing fluids when evaluated by a diesel injector apparatus procedure that uses European diesel injector test equipment. The viscosity loss reflects polymer degradation due to shear at the nozzle.

2. This test method evaluates the percent viscosity loss for polymer-containing fluids resulting from polymer degradation in the high shear nozzle device. Thermal or oxidative effects are minimized.

Product feature:

1.Original German Bosch jet pump with nozzle and atomizing chamber;

2. Bowch-type axial nozzle injector, the nozzle bracket has a filter cartridge;

3. The spherical cooler is equipped with a cooling jacket, which can effectively cool the oil sample and ensure that the temperature of the oil sample is between 30 and 35 °C;

4. The liquid flow meter controls the flow rate, digital display, 170cm3±5cm3/min;

5. The automatic stroke counter can automatically cut off the power supply;

6. Three-phase motor, power 1100W, speed 925±25r/min;

7. There is a distribution plate in the glass test tube, and there is a three-way piston at the cooling outlet;

8. Microcomputer temperature controller, digital display, accuracy ±1℃, PT100 sensor;

9. Fully enclosed compressor refrigeration, large cooling capacity and low noise;

10. Digital timer records the test time with wind sound;

11. Independent desktop controller, highly integrated function buttons, easy to operate;

12. There is an electronic controller to control the pressure on the pressure pipeline, and the digital display pressure is 17.5Mpa±0.35Mpa.

13. Instrument size: host: 800*250*1100mm; circulating water bath: 240*510*670mm;

14. Net weight: 56KG

|

item |

Value |

|

Warranty |

1 Year |

|

Customized support |

OEM, ODM, OBM, Software reengineering |

|

Place of Origin |

China |

|

|

Chongqing |

|

Brand Name |

GOLD |

|

Model Number |

GD-H1358 |

|

Power |

2.5KW |

|

Applicable standard |

ASTM D6278, SH/T0103 |

|

Timing method |

Digital timer |

|

Counting method |

Automatic stroke counter |

|

Refrigeration method |

Compressor refrigeration |

|

Temperature control range |

35±0.2℃ |

|

Circulation mode |

Magnetic pump circulation |

|

Flow rate control |

Liquid flow meter |

|

Pressure control |

Pressure transmitter, digital display |

|

Machine power |

2.5KW |

|

Working power supply |

AC220,240V/50,60Hz |

Our services:

Service:

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days.

We can offer operation video and English operation muanual. We can provide video.

Onsite Service:

1.Device installation; 2.Equipment Operation Test Technology training;3.Daily maintenance and maintenance of equipment; 4.Free technical training for visiting factories; 5.Free software upgrades;

Device Problem Handling:

1. Social media 24 hours online communication;2. Mail Seamless Docking;3. Video Conferencing;

Contact us:

When you have any comments or requirement on the petroleum testing apparatus producer and Diesel Fuel Nozzle Shear Stability Tester in ASTM D6278 for Polymer oil. Please kindly leave your message and email address here! Let's have a detail communication or You can click on the image below: