- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

150000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V

-

Machinery Capacity:

-

50 Ton

-

Name:

-

Paper Making Machine

-

Width:

-

1800mm,2000mm, 5200mm

-

Heat Type:

-

Steam,electric, thermal oil

-

Keyword:

-

tissue paper making machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Total Power:

-

500kw

-

Machine weight:

-

150000Kg

-

Work Speed:

-

10-200 TPD

-

Certification:

-

ISO

-

Production capacity:

-

100t

Quick Details

-

Brand Name:

-

YG

-

Year:

-

2024

-

Dimension(L*W*H):

-

50X 5 X 6 M

-

Weight:

-

150000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V

-

Machinery Capacity:

-

50 Ton

-

Name:

-

Paper Making Machine

-

Width:

-

1800mm,2000mm, 5200mm

-

Heat Type:

-

Steam,electric, thermal oil

-

Keyword:

-

tissue paper making machine

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Total Power:

-

500kw

-

Machine weight:

-

150000Kg

-

Work Speed:

-

10-200 TPD

-

Certification:

-

ISO

-

Production capacity:

-

100t

Paper Making Machine

Product Description

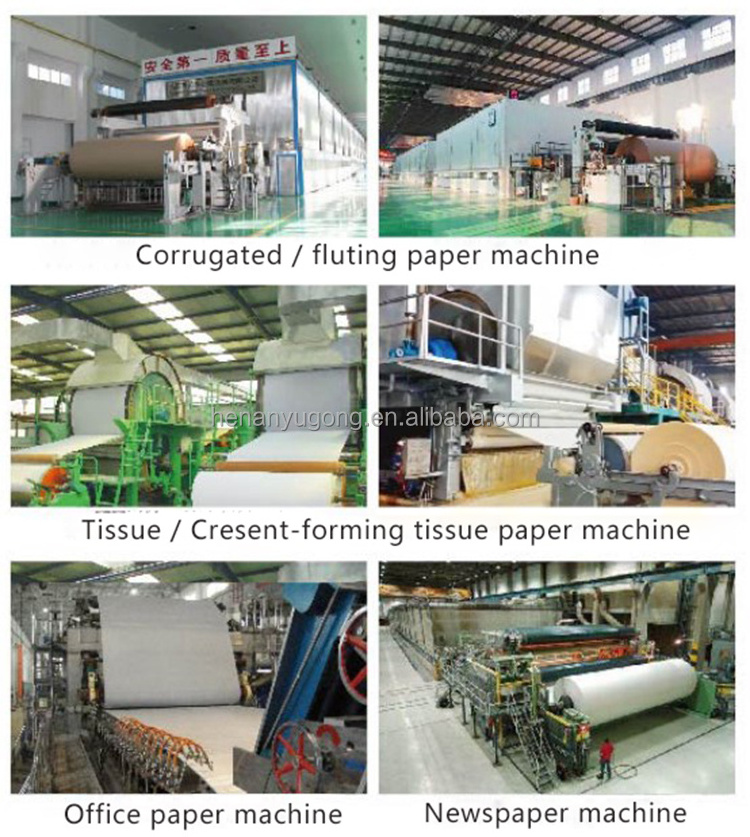

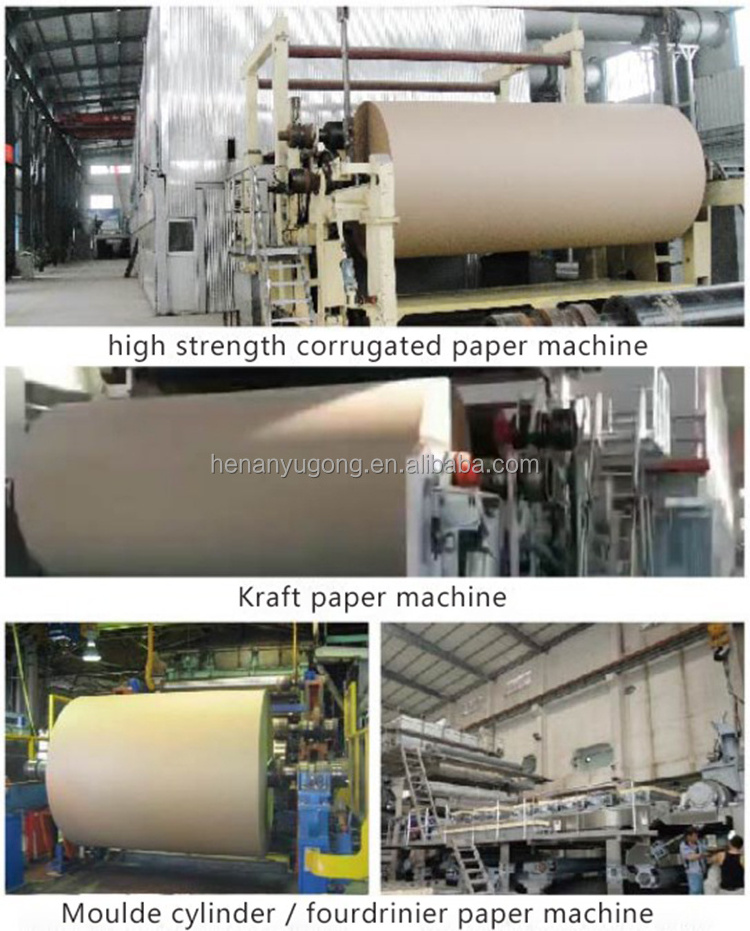

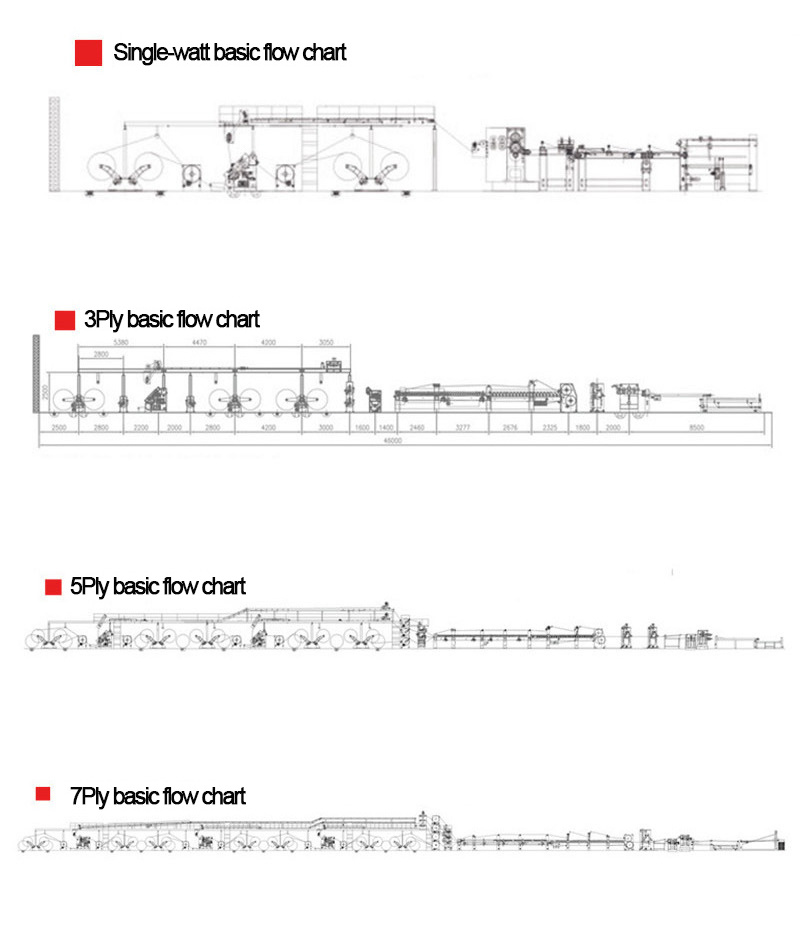

Corrugated cardboard production line

Corrugated cardboard production line is the professional equipment for producing corrugated cardboard. The production line consists of the Mill Roll Stand ,liner(medium paper) pre-heater, single facer machine, conveyor bridge, gluing machine, double facer machine, slitter scorer, cut-off, conveyer and stacker, heating system, air compression system and glue macking system and so on. We produced different grade 3,5,7 ply corrugated production line with different fitting. On the base of understanding the requirements of the customers and the advanced skills at home and abroad, our company has developed and designed these production lines with the speed 60—220m/min; the paper width 1600-2200mm and A,B,C,E UV flute production line can satisfy different customers.

Product Details

Automatic Corrugated cardboard production line

1. Corrugated cardboard production line is the professional advanced equipment for produce 3ply, 5ply, 7ply corrugated cardboard.

2. Different models and quantities equipment can compose different models and grades production line.

3. Our company has developed and designed these 3, 5, 7 layer corrugation line with the speed 80-220m/min;the paper width 1400-2200mm and A/C/B/E flutes for customer to choose from,the flute shape is UV shape and more like V shape.

4. The production line consists of mill roll stand, pre-heater, single facer machine, conveyor bridge, gluing machine, double baker, slitter scorer machine, NC cut-off, conveyor and stacker, heating system. Air compression system, glue making system etc.

2. Different models and quantities equipment can compose different models and grades production line.

3. Our company has developed and designed these 3, 5, 7 layer corrugation line with the speed 80-220m/min;the paper width 1400-2200mm and A/C/B/E flutes for customer to choose from,the flute shape is UV shape and more like V shape.

4. The production line consists of mill roll stand, pre-heater, single facer machine, conveyor bridge, gluing machine, double baker, slitter scorer machine, NC cut-off, conveyor and stacker, heating system. Air compression system, glue making system etc.

Product Advantage

Corrugated carton production line

The assembly line for automated mass production, can produce good national standard corrugated cardboard, high efficiency, good quality board to take centralized control, easy operation, easy maintenance, safety and reliability, greatly reduced the labor intensity. The production line using the latest international energy-saving way to provide high temperature heat source Daore You to machine than the steam heating energy savings above 60%, significantly reducing power consumption, effectively reduced the cost of production, is the ideal product for today's economy and medium-sized carton factory.

Technical Parameters

|

Width

|

1600~2200mm

|

|

Speed

|

150M/min

|

|

Number of slitting knives

|

5Pcs

|

|

Minimum slitting width

|

180mm

|

|

Cross cut length

|

300~9999mm

|

|

Stomping height

|

250~600mm

|

|

Maximum cardboard stamping length

|

1600mm

|

Product Display

Main equippment list

1. mill roll stand (mechanical and hydraulic shaftless is available)

2. splicer(option, it is used for high speed production line)

3. single facer

4. Preheater

5. Multi-preheater

6. Gluing machine

7. Double facer

8. Thin blade slitter scorer(simple type, up-down type, and computer control for options)

9. NC cut-off(servo control, straight and helical)

10. Stacker and delivery machine

11. Paste making system

12. Accessories(air compressor, operation box, pipe)

2. splicer(option, it is used for high speed production line)

3. single facer

4. Preheater

5. Multi-preheater

6. Gluing machine

7. Double facer

8. Thin blade slitter scorer(simple type, up-down type, and computer control for options)

9. NC cut-off(servo control, straight and helical)

10. Stacker and delivery machine

11. Paste making system

12. Accessories(air compressor, operation box, pipe)

Product Packaging

Packaging

After the machine is finished and running well, it will be coated with anti-rust oil, which makes the machine not easy to rust in the container, and winding film to prevent moisture. Each unit of the machine will be fixed in the container to ensure a stable and safe arrival at the destination.

Our Company

Hot Searches