- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PJ-60

-

Product name:

-

A new PJ-60 injector calibration device

-

Color:

-

RED

-

Function:

-

Test diesel nozzle

Quick Details

-

Power:

-

Electronic

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAOSHIYUAN

-

Model Number:

-

PJ-60

-

Product name:

-

A new PJ-60 injector calibration device

-

Color:

-

RED

-

Function:

-

Test diesel nozzle

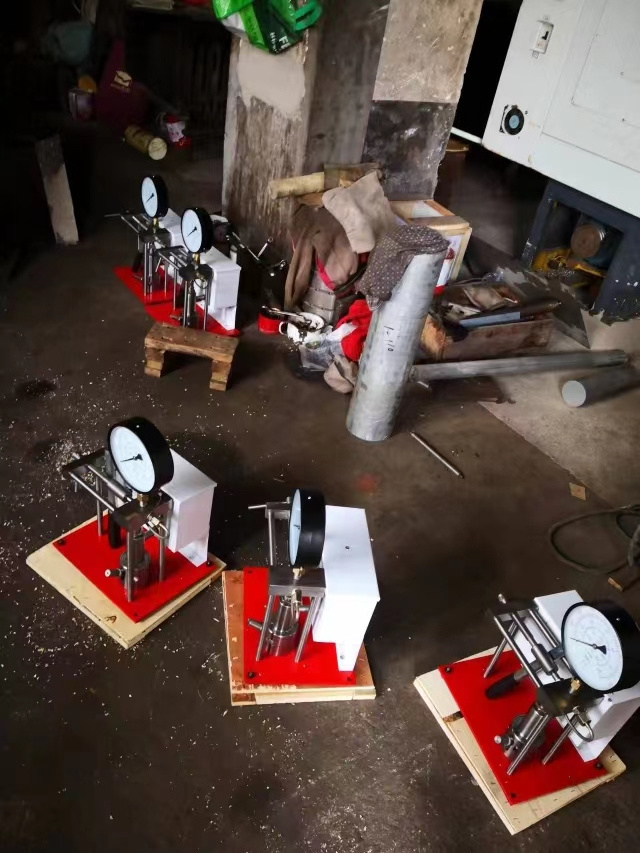

PJ 60 NOZZLE INJECTOR TESTER

Characteristics and Usage:

The characteristics of Nozzle Tester is quick to lift pressure, nice voltage stabilization,reasonable structure, smart operation, easy packing, is an ideal instrument to calibrate the injection pressure, fuel atomization quality,injection angle and tightness of the needle valve of the diesel injector assembly.

Instructions before use in the RFQ, please read it carefully

Main Features

1. It is the feature of pressure rise speed, good voltage regulation performance, reasonable structure, flexible operation, packaging and more convenient to carry.

2.It is mainly used to inspect and test the injection opening pressure of diesel engine assembly and atomization quality, spray Angle and needle valve closure.

|

Main parameter

|

|

|

|

|

|

|||

|

Type

|

Pressure gage range (Mpa.)

|

Overall dimensions

L×W×H (mm)

|

Capacity of fuel tank

(L)

|

Largest pressure tested

(Mpa.)

|

Net weight (Kg)

|

|||

|

PJ60(Black)

|

0-60

|

330×292×510

|

1.0

|

60

|

20

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

|

PJ60(Red)

|

0-60

|

330×292×510

|

1.0

|

60

|

20

|

|||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

Payment terms: FOB QingDao 50% deposit, 100% before shipment from the factory

Shipment: container

The mode of transportation: choose by the buyer

Freight: paid by the buyer

Peration and adjustment

Use detector shoud check whether fixed firmly ,working environment should be clean,detector especially the clamping injector connector should wipe clean,then add precipitation over 48 hours of 0 # light diesel oil,don't use unqualified diesel.

The injector assembly opens pressure test:

First of all we can put booster leverage in bracket center,then we should turn the screw on the bracket and screw it on the high-pressure tube. fix firmly the injector assembly, check the sealing installation, push rod pumping pressure in sex, and see the pressure gauge, hands for the highest number display that the injector open pressure, cannot be used bracket to Fixed the injector body, spin screw under the right, fixed the injector assembly before the test. If open pressure beyond the prescribed scope of stress, adjust the pressure injectors springs, until the requirements.

The injector assembly injection Angle

Test the injecting angle ensure the injecting pressure is adjusted.Put a piece of white paper or a piece of iron-wire net painted with grease under the nozzle in the Repeat to pump fuel until you can see clearly a fuel circle or an empty circle in the iron-wire net.Measure height of “H” from the mouth to the net(paper) and diameter of outer circle D.Injecting angle.

Experiment of Atomizing Quality

Watch the atomizing quality of fuel injecting.The fuel grain should be tiny,well distributed.No fuel current (or drop) seen with eye.No obvious fuel stain appears if it is injected on the oil absorbing paper.Color of fuel stain from center to outer circle should become lighter and from well distributed circle.Pumping fuel should be quick.There is no fuel drop or fuel dropping after pumping fuel.Atomizing should be correct.Its taper angle should be within specified range.

Maintenance of the nozzle tester

Calibrating fuel must be good quality light diesel deposited over48 hours.

When filling fuel,filter it with silk-cloth.Do not fill tank with unfiltered diesel.

Cover the tester with anti-dust cover after testing.

Should be regularly (half year) to examine the pressure gage.

Without refueling, can’t press pressure rod, lest damage piston.