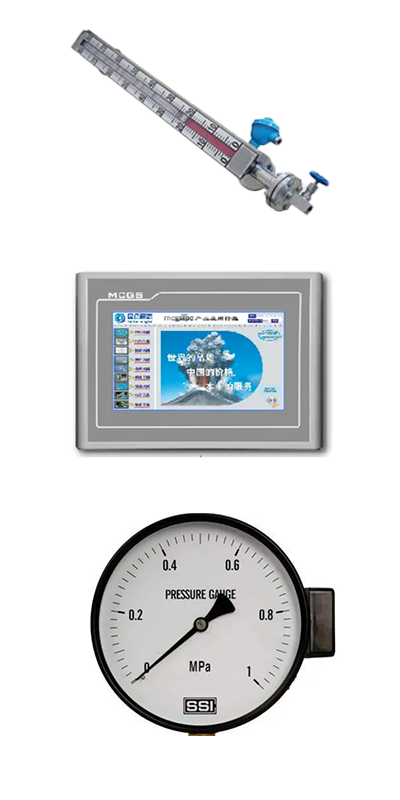

Electric automatic control

Automatic control in temperature, pressure, sterilizing time,etc.

Safe operation

Electric and mechanical double interlock protection system for safe information

Over pressure protection

Electric and mechanical double over pressure system for safe operation.

Over temperature protection

Electric over temperature protection system.

Equalized heat distribution

The temperature inside the sterilizer is equalized distribution, which means the temperature difference will be controlled less

than 0.5 ℃.

Low temperature difference

Electronic type

Humanization design and long lifespan material

Stainless steel material, high intelligent automatic control system.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

30KW to 120KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

2000*1500*1800 mm

-

Product name:

-

ASME certificate food autoclave machine

-

Application:

-

food/ beverage

-

Sterilizing way:

-

water spray

-

Material:

-

Stainless Steel SUS304/316

-

Control system:

-

Automatic Control System

-

Working temperature:

-

121 Degree Centigrade

-

Heating Method:

-

boiler or electricity

-

Advantage:

-

High Efficiency Low Cost

-

Function:

-

High Temperature High Pressure Sterilizing

-

Keywords:

-

steam canned food autoclave

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sensitar

-

Voltage:

-

220V/230V/380V/415V/420V

-

Power:

-

30KW to 120KW

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

2000*1500*1800 mm

-

Product name:

-

ASME certificate food autoclave machine

-

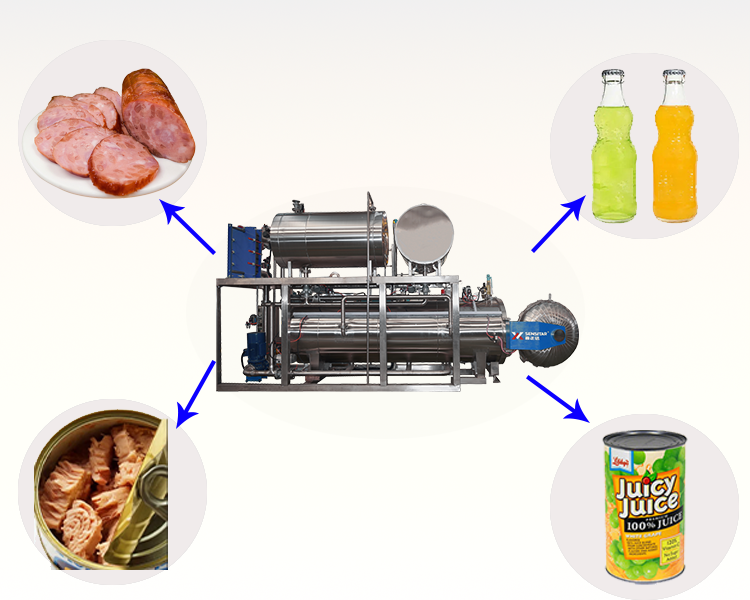

Application:

-

food/ beverage

-

Sterilizing way:

-

water spray

-

Material:

-

Stainless Steel SUS304/316

-

Control system:

-

Automatic Control System

-

Working temperature:

-

121 Degree Centigrade

-

Heating Method:

-

boiler or electricity

-

Advantage:

-

High Efficiency Low Cost

-

Function:

-

High Temperature High Pressure Sterilizing

-

Keywords:

-

steam canned food autoclave

Product Description

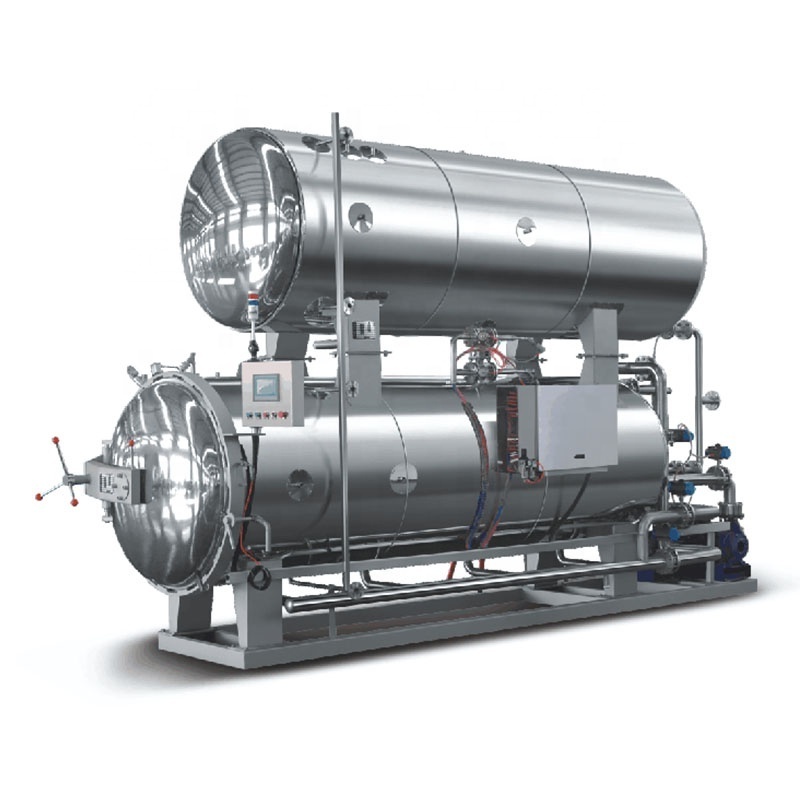

Stainless steel ASME certificate industrial retort sterilizer steam canned food autoclave machine price

Stainless steel ASME certificate industrial retort sterilizer steam canned food autoclave machine price

can

prevent pollution and achieve international food sanitation standard. Before sterilization , horizontal sterilization pot can be heated ahead of time to make the temperature over 100°C under the conditional of dry air within the kettle ,which can reduce sterilization time and ensure the dry and wet degree of materials. This kind of sterilizing kettle can be applied to assembly line work.

PLC with touchscreen monitor for quick and easy process control.

Regular Model

The Model showed on the following table is our regular machine.

We also support machine customization service.

|

Model

|

XZDR-700

|

XZDR-900

|

XZDR-1000

|

XZDR-1200

|

|||

|

Inner Diameter(mm)

|

700

|

900

|

1000

|

1200

|

|||

|

Length (mm)

|

1200

|

1800

|

2200

|

3600

|

|||

|

Material

|

SUS 304/316

|

|

|

|

|||

|

Voltage

|

220V/240V/380V/400V/480V

|

|

|

|

|||

|

Designed Temperature

|

145℃

|

|

|

|

|||

|

Test Pressure

|

0.44Mpa

|

|

|

|

|||

Application scope

Steam sterilization Autoclave Retort for sardines and tuna canned food producing

has been widely used in food industry and pharmaceutical industry. It has wide application for vacuum packaged product, such as flexible package, CPP+PA, can, glass bottle, aluminum foil, tinplate, plastic, etc.

Our Advantages

Advantages

More recommend

Packing & Delivery

We usually pack our products by standard export cartons as master carton. We always choose the best and safe packaging material to make sure your orders won't be damaged during delivery.

Hot Searches