- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CMIENSEM

-

Model Number:

-

EA

-

Name:

-

Magnetic Liquid Level Gauge

-

Measuring range:

-

300mm-6000mmCustomizable

-

Installation mode:

-

side installation, top installation

-

Display mode:

-

on-site direct reading, limit alarm, remote transmission

-

Output:

-

4-20mA

-

Temperature:

-

-20~80C,80~480C

-

Pressure:

-

0-2.45Mpa,2.45-9.6Mpa

-

Precision:

-

5mm

-

Body tube material:

-

SUS304,SUS316L,PP,PTFE

-

Float material::

-

SUS316L,PP,PTFE

Quick Details

-

Grade:

-

DIY, Industrial

-

Warranty:

-

1 year

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

CMIENSEM

-

Model Number:

-

EA

-

Name:

-

Magnetic Liquid Level Gauge

-

Measuring range:

-

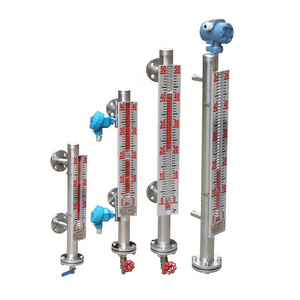

300mm-6000mmCustomizable

-

Installation mode:

-

side installation, top installation

-

Display mode:

-

on-site direct reading, limit alarm, remote transmission

-

Output:

-

4-20mA

-

Temperature:

-

-20~80C,80~480C

-

Pressure:

-

0-2.45Mpa,2.45-9.6Mpa

-

Precision:

-

5mm

-

Body tube material:

-

SUS304,SUS316L,PP,PTFE

-

Float material::

-

SUS316L,PP,PTFE

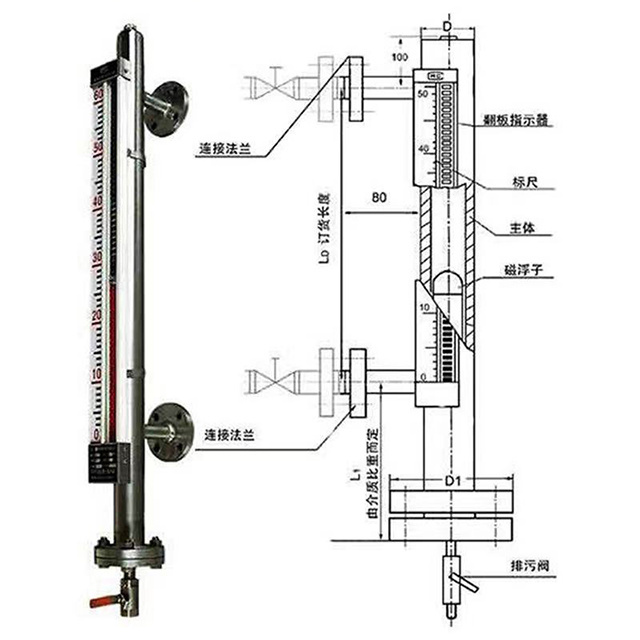

Magnetic flap level gauge

How it works

The extension bypass tube is installed on the outside of the barrel tank, and the liquid level indicator is installed outside the bypass tube. The float ball equipped with a magnet is put into the bypass tube. Because the magnet is installed in the magnetic flip bead, the magnetic flip bead will attract the magnetic flip bead when the float ball rises, and the color of the magnetic flip bead will be turned from white to red to indicate the current liquid level. In addition, the outer side of the bypass tube can be equipped with a magnetic switch to output electrical contact signals, or a liquid level transmitter can be installed for long-distance liquid level signal transmission and liquid level control.

Features

•

Compared with the traditional glass tube, the plate level gauge has higher reliability, safety and practicality

•

The application of advanced cold rolling hole drawing welding and other high quality technology

•

Can be used for high temperature, high pressure, strong acid and alkali, explosion-proof and other special working conditions

•

Simple structure, reliable and durable, can be installed liquid level transmitter and magnetic switch to make the control more convenient

•

If the power supply is interrupted during work, the field magnetic switch is not affected, and the accuracy is high

•

Two different colored beads make the liquid level easy to identify

|

Type

|

Field of application

|

|

Side flange standard

|

industry

|

|

Side mount lined with teflon

|

Wastewater treatment

|

|

Side mounted thread standard

|

Power station

|

|

Top mounted standard

|

Hot kerosene boiler

|

Product details

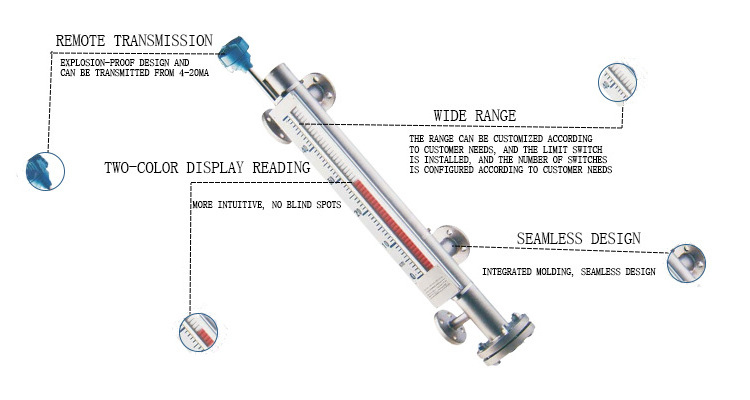

Remote transmission: explosion-proof design and can be transmitted from 4-20mA

Seamless design: integrated molding

Wide range: the range can be customized according to customer needs, and the limit switch is installed, and the number of switches is configured according to customer needs

Two-color display reading: more intuitive, no blind spots

Common faults and troubleshooting methods

|

Fault phenomenon

|

Cause analysis

|

Elimination method

|

|

The water level rises or falls, the float does not move

|

1. Media precipitation or foreign matter into the body tube stuck float ball

2. Float the ball into water

3. The outer wall of thebody tube is close to the magnetic conductive material

|

1. Clean the body pipe with water in time

2. Replace the float

3. Isolate the magnetic conductive material

|

|

The actual liquid level is out of sync with the duplicate display

|

The specific gravity of the medium does not conform to the specifications of the float

|

Reselect the float

|

|

The flip board is displayed randomly

|

The liquid level rising speed should be less than 0.8 m/s

|

Reduce the liquid level rise rate

|

|

The flange connecting plate is leaking

|

Gasket aging

|

Replace the material gasket with the same specification

|

|

The transmitter is not working properly

|

1. The supply voltage is not 13-36VDC

2. The cable is in poor contact

|

1. Adjust the supply voltage

2. Check the cable connection

|

|

Limit switch does not move

|

The gap between the limit switch and the body tube is too large

|

Hold the limit switch against the tube wall

|

Hot Searches