- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GD

-

Dimension(L*W*H):

-

1050*560*920mm

-

Weight:

-

120 KG

-

Material:

-

Stainless Steel

-

Function:

-

Preserved Food

-

Usage:

-

Food Vacuum Package

-

Product name:

-

Vacuum Packaging Machinery

-

Advantage:

-

Easy Operate

-

MOQ:

-

1 set

-

Feature:

-

High Level High Speed

-

After Warranty Service:

-

Service

-

Product Keywords:

-

Double Vacuum Sealing

-

Main Products:

-

Frozen Food Vacuum Packing Machine

Quick Details

-

Packaging Type:

-

Bottles, Bags, Pouch

-

Packaging Material:

-

Plastic

-

Voltage:

-

220v

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GD

-

Dimension(L*W*H):

-

1050*560*920mm

-

Weight:

-

120 KG

-

Material:

-

Stainless Steel

-

Function:

-

Preserved Food

-

Usage:

-

Food Vacuum Package

-

Product name:

-

Vacuum Packaging Machinery

-

Advantage:

-

Easy Operate

-

MOQ:

-

1 set

-

Feature:

-

High Level High Speed

-

After Warranty Service:

-

Service

-

Product Keywords:

-

Double Vacuum Sealing

-

Main Products:

-

Frozen Food Vacuum Packing Machine

Product Description

Introduction:

The double-chamber vacuum packaging machine is used in the food industry, after vacuum packaging, the food can resist oxidation, so as to achieve the purpose of long-term preservation. It is a small packaging machine for vacuum packaging.

Product Paramenters

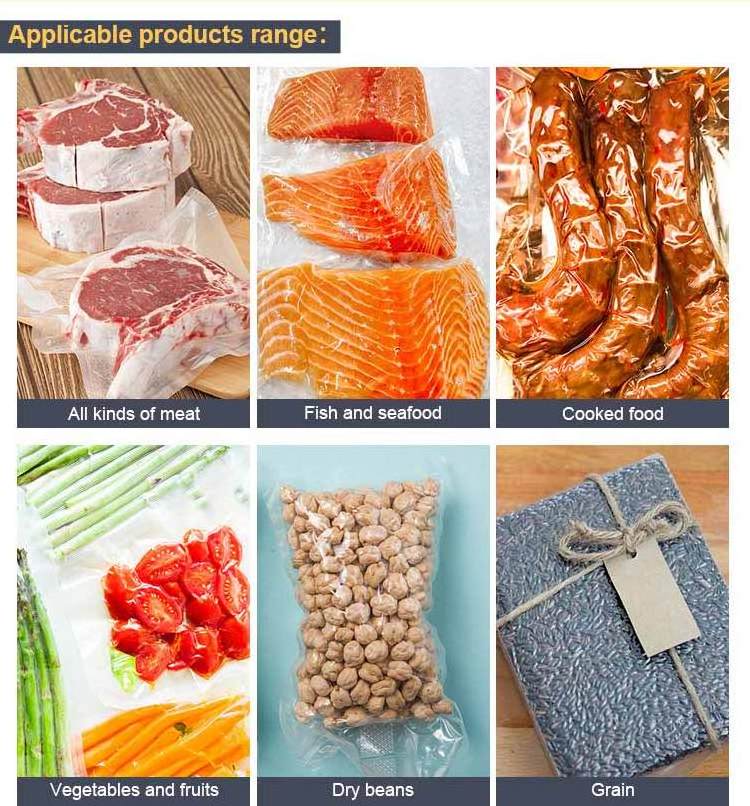

Application

:

For solid, liquid, powder, paste, food, fruit, seeds, vegetables. Vacuum packaging of chemical products, electronic components, precision instruments, rare precious metals and other items.

|

Parameter:

|

|

|

|

|||

|

Model

|

GD-400

|

Sealing width

|

10

|

|||

|

Voltage

|

380/50 220/50

|

Vacuum pump rate

|

20

|

|||

|

Motor power

|

1000

|

Material for vacuum chamber

|

stainless steel

|

|||

|

Sealing power

|

700

|

Dimension(mm)

|

1050*560*920

|

|||

|

Ultimate vacuum pressure

|

1

|

Net weight

|

120kg

|

|||

|

No.of sealing bars for each chamber

|

2

|

Packing size(mm)

|

1130*730*1030

|

|||

|

Chamber dimension

|

460*460*140

|

Gross weight

|

140kg

|

|||

|

Sealing length

|

400

|

can be customized

|

|

|||

Features

:

1.Superior function,Easy to maintain

2,Easy to operate

2,Easy to operate

3,Wide range of applications

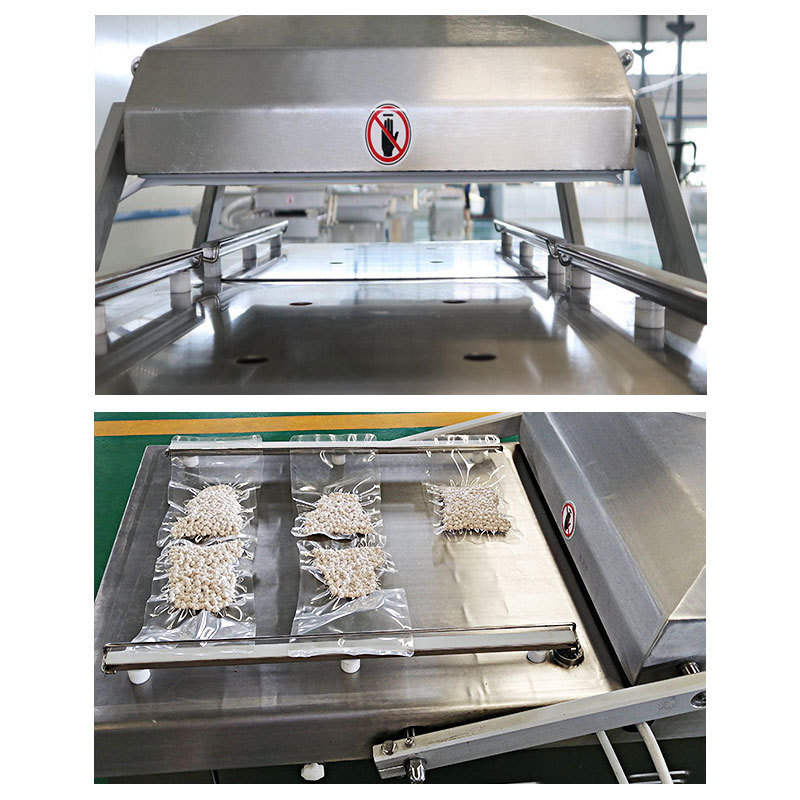

Product Detail

Processing procedure

:

Operation steps

1.

Turn on the power.

2.

Turn on the power switch and set the vacuum time according to the requirements of vacuum packaging.

3.

Set the sealing temperature and sealing time according to the material of the vacuum bag.

4.

Place the product on the sealing strip.

5.

Depress the vacuum cover to start vacuuming, and another vacuum chamber starts to place the product.

6.

When a certain vacuum thickness is reached, enter the sealing process.

7.

After the sealing is completed, enter the cooling state, then deflate, and the packaging is completed.

8.

Press the vacuum chamber cover to the other vacuum chamber to start another vacuum cycle.

Note: This product has the function of vacuum pumping and sealing at one time. The degree of vacuum is adjusted by the time

potentiometer setting switch, and the sealing temperature is adjusted in five steps. Different sealing temperatures are achieved

by the heating voltage of the transformer. The heat sealing time is digitally displayed. relay to control

FAQ

Packaging & Shipping

Hot Searches