- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V, 220/380 V 50Hz or customize

-

Power:

-

45-200KW, 45-200 KW

-

Dimension(L*W*H):

-

20-85*4.5*3.5m

-

Weight:

-

25-30tons

-

Warranty:

-

1-2years

-

Function:

-

Paper lamination --gluing --cutting

-

Max Paper Rolls Width:

-

1600 mm or customize

-

Board Thickness:

-

1-6 mm

-

Max Working Speed:

-

80 m/min

-

Cutting Accuracy:

-

±1mm

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

YALIAN

-

Model Number:

-

1100-1650MM

-

Voltage:

-

220V/380V, 220/380 V 50Hz or customize

-

Power:

-

45-200KW, 45-200 KW

-

Dimension(L*W*H):

-

20-85*4.5*3.5m

-

Weight:

-

25-30tons

-

Warranty:

-

1-2years

-

Function:

-

Paper lamination --gluing --cutting

-

Max Paper Rolls Width:

-

1600 mm or customize

-

Board Thickness:

-

1-6 mm

-

Max Working Speed:

-

80 m/min

-

Cutting Accuracy:

-

±1mm

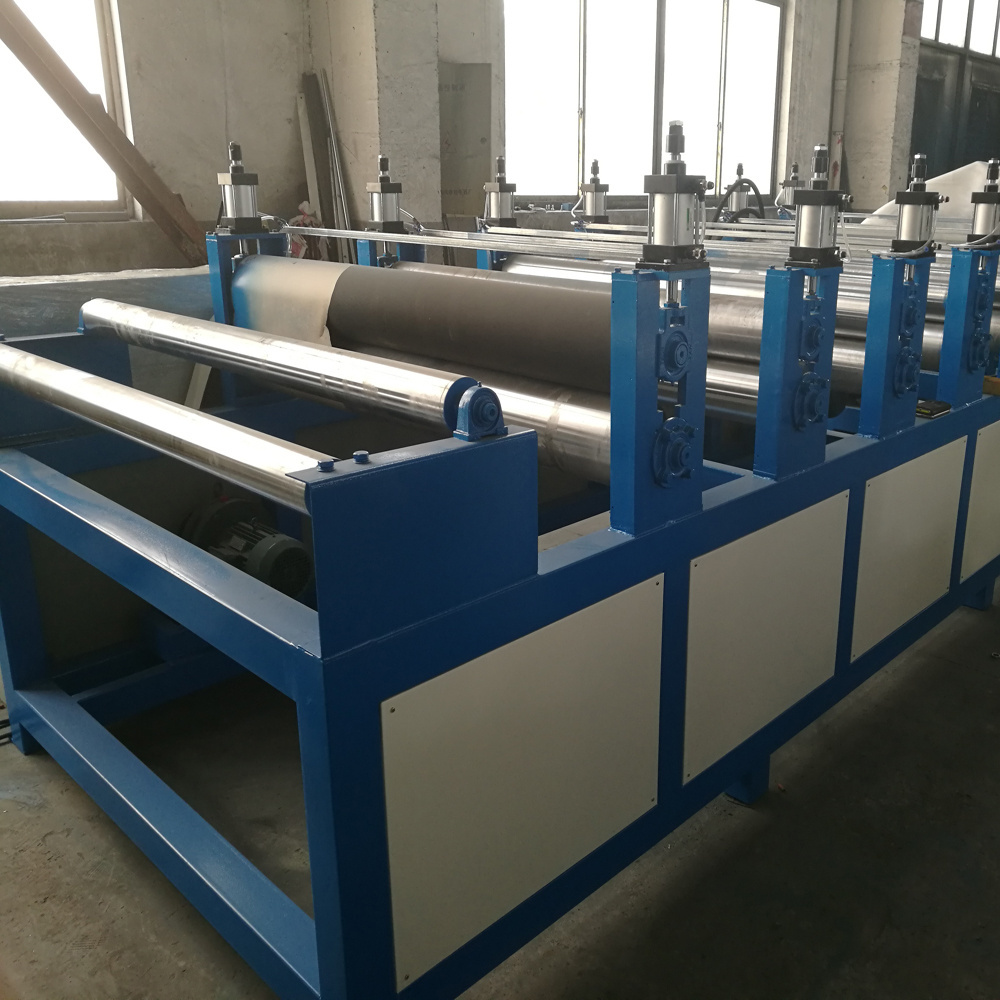

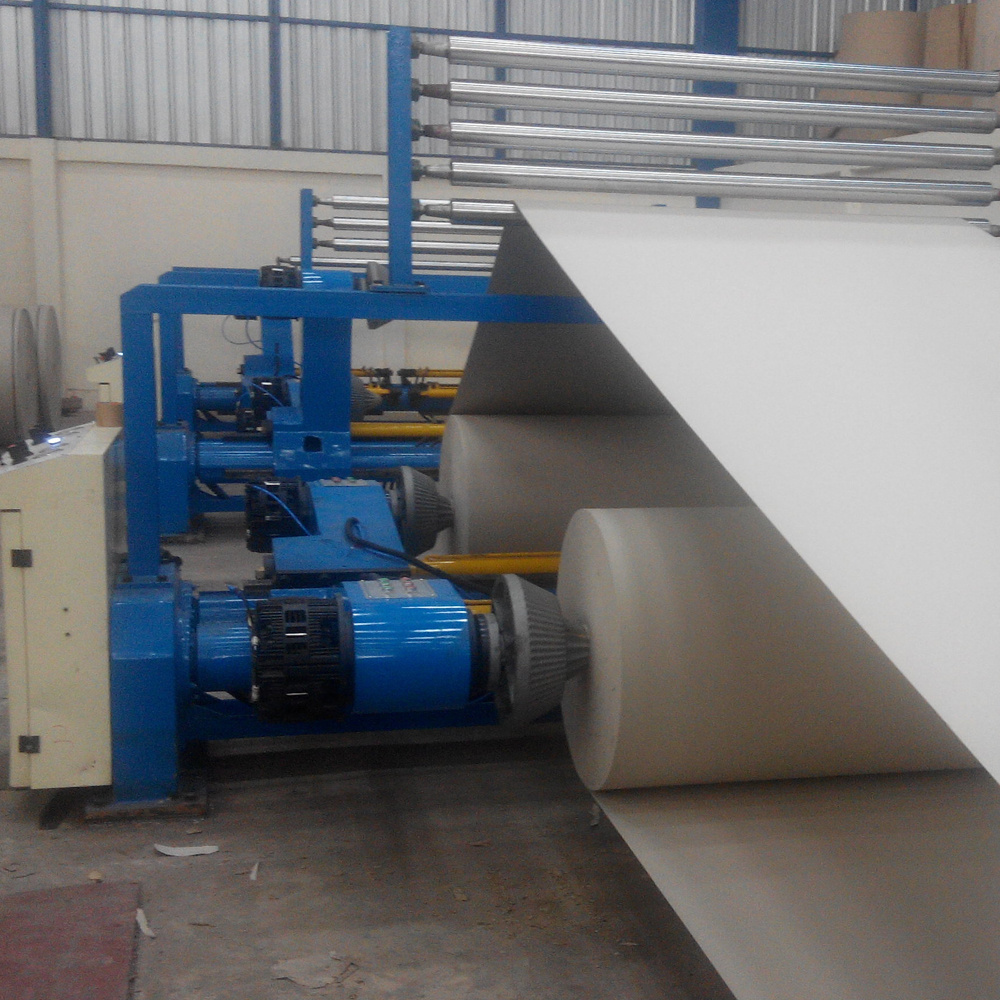

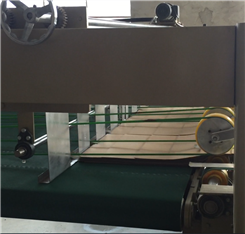

Automatic cardboard paper compress machine

This machine is for paper lamination, the proceed as following:Paper Roll Loading -> Pre-heating -> Gluing -> Pressing ->Drying>Pressing -> Board Slitting -> Board Cutting -> Conveyor. This machine make 2-6 layers paper cardboard which can widely use in slip sheet for packing industrial or packing box or electrical insulating board.

Pre-heating

Die-cutting available

Auto Stacking available

Main Features:

1)Working paper rolls width 700--1600mm, we also can customize!

2)Lamination speed: 0--80m/min depends on cutting type

3)Electric or Steam heating both available

4)With or without heating chamber both available

5)

Superior cutting system with Servo control

6)No bubbles or wrinkles on the board surface

•Widely using in goods transportation to replace the pallet

Carton Box

•Widely using in Mobile or small electric appliance packing

Electrical Insulating Board

•Widely using in transformer

Mechanical Paper Mill Stand

•Paper roll setting with Mechanical control

•Paper roll handling toward up or down and left or right

•With extension structure for different width paper rolls

Hudraulic Paper Mill Stand

•Paper roll setting with Hydraulic control

•Paper roll handling toward up or down and left or right

•With auto tension controller- electric control

•With extension structure for different width paper rolls

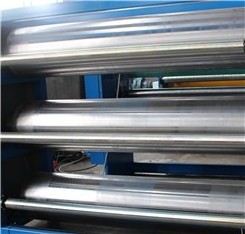

Pre-heating

•Preheating roller diameter: Φ350mm

•Automatic temperature control

Gluing Machine

•Stainless steel SS316 rollers with diameter of Φ156mm

•With glue auto recycle system

Pressing

•Steel or rubber rollers diameter of 220mm with driver

•Groups of pressing rollers can customize

Drying

•Electric or steam both available,hot air recycle heating

•Normal length 8( length can customize)

Roller Pressing

•15 Groups forming rollers or customize quantity

•Length 4-10m or customize

Slitting

•4 pcs knives with diameter of 140mm

•Rubber pressing roller diameter of 235, hardness 90 degree

Hydraulic Cutting

•Cutting speed 0-25m/min

•Cutting thickness 1-6mm

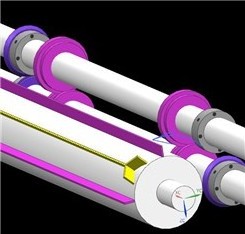

Double Spiral Cutting

•Cutting speed 0-80m/min

•Cutting thickness 1-3.5mm

Die-Cutting

•Cutting speed 0-35m/min

•Cutting thickness 1-3mm

Lifting Stacking

•For max speed of 25m/min

Fast Speed Stacking

•For max speed of 40m/min

HIgh Speed Stacking

•For max speed of 80m/min

Pre-Sales Service

* Inquiry and consulting support.

* Machine Design and Quotation Sheet with Technical Details

* View our Factory and See the Machine Running

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Honeycomb Machine

91.8% Response Rate

Re-board Machine

91.8% Response Rate

Edge Board Machine

91.8% Response Rate