- Product Details

- {{item.text}}

Quick Details

-

Blade Width:

-

Other

-

Arbor Size:

-

NO

-

Teeth per Inch:

-

standard

-

Teeths:

-

standard

-

Blade Diameter:

-

standard,customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

Model Number:

-

carbide band saw blade

-

Product Name:

-

carbide band saw blade

-

Blade Material:

-

carbide

-

Feature:

-

Cuts tougher,Cuts smoother,Cuts safer,Cuts better

-

Application:

-

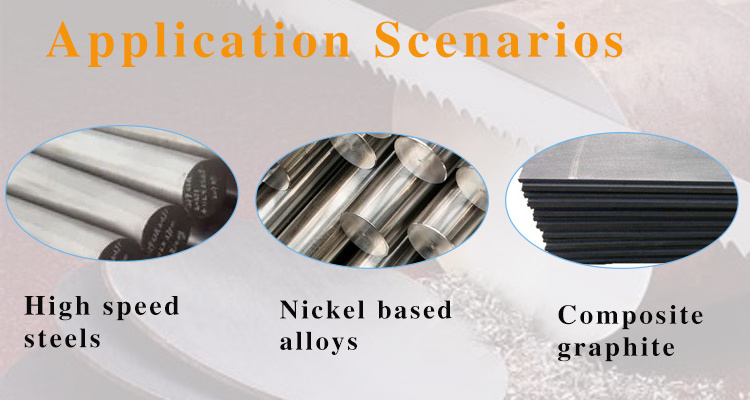

cutting nickel based alloys, case hardened steels, inconnel,etc

-

Diameter:

-

standard,customized

-

Package:

-

Carton

-

MOQ:

-

1Piece

-

Type:

-

Band Saw Balde

-

Quality:

-

Excellent

Quick Details

-

Blade Length:

-

standard,customized

-

Finishing:

-

Nitride

-

Size:

-

Standard,customized, 27*0.9*3152,27*0.9*3160,34*1.1*3680,customized

-

Blade Width:

-

Other

-

Arbor Size:

-

NO

-

Teeth per Inch:

-

standard

-

Teeths:

-

standard

-

Blade Diameter:

-

standard,customized

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

Model Number:

-

carbide band saw blade

-

Product Name:

-

carbide band saw blade

-

Blade Material:

-

carbide

-

Feature:

-

Cuts tougher,Cuts smoother,Cuts safer,Cuts better

-

Application:

-

cutting nickel based alloys, case hardened steels, inconnel,etc

-

Diameter:

-

standard,customized

-

Package:

-

Carton

-

MOQ:

-

1Piece

-

Type:

-

Band Saw Balde

-

Quality:

-

Excellent

Related Products

Products Description

About Carbide Band Saw Blade

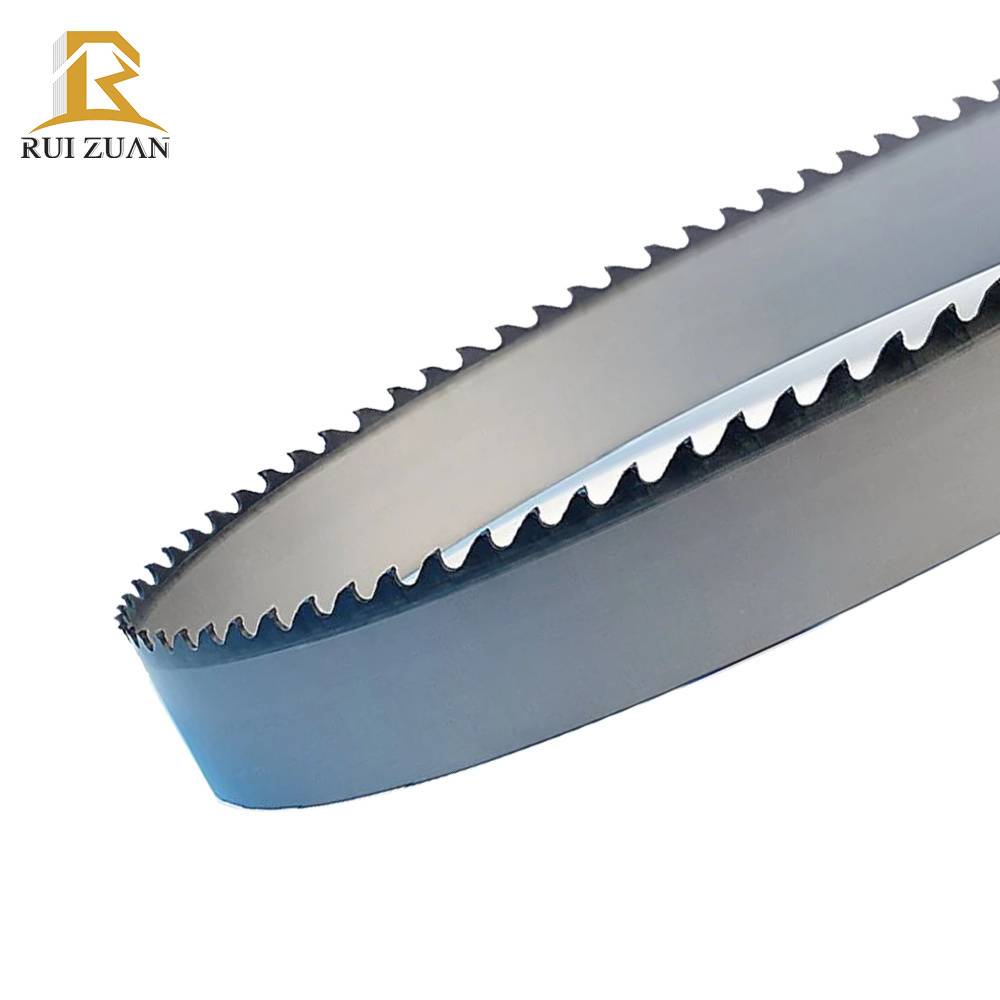

Our Carbide Foundry blade is the result of the finest Chinese engineering for the cutting of non-ferrous metals.

It allows you to perform contour and radius cutting on non-ferrous casting using Automatic or , especially, Manual saws

The extras wide set prevents pinching, while the ground trapezoid tooh and positive rake angle allow for a smooth cut that prevents abrasion and leaves a nice finish.

Carbide grit blades are your solution to easily cut through materials those conventional band saw blades won’t cut. Extremely useful in cutting complex shaped materials, thin materials, case hardened steels, fiber reinforced plastics and composite graphite.

We have different shapes, accept customization.Blade length should be ordered at the mid-point of manufacturer’s recommendation to allow for take up.

Advantages

1.Cuts life longer:

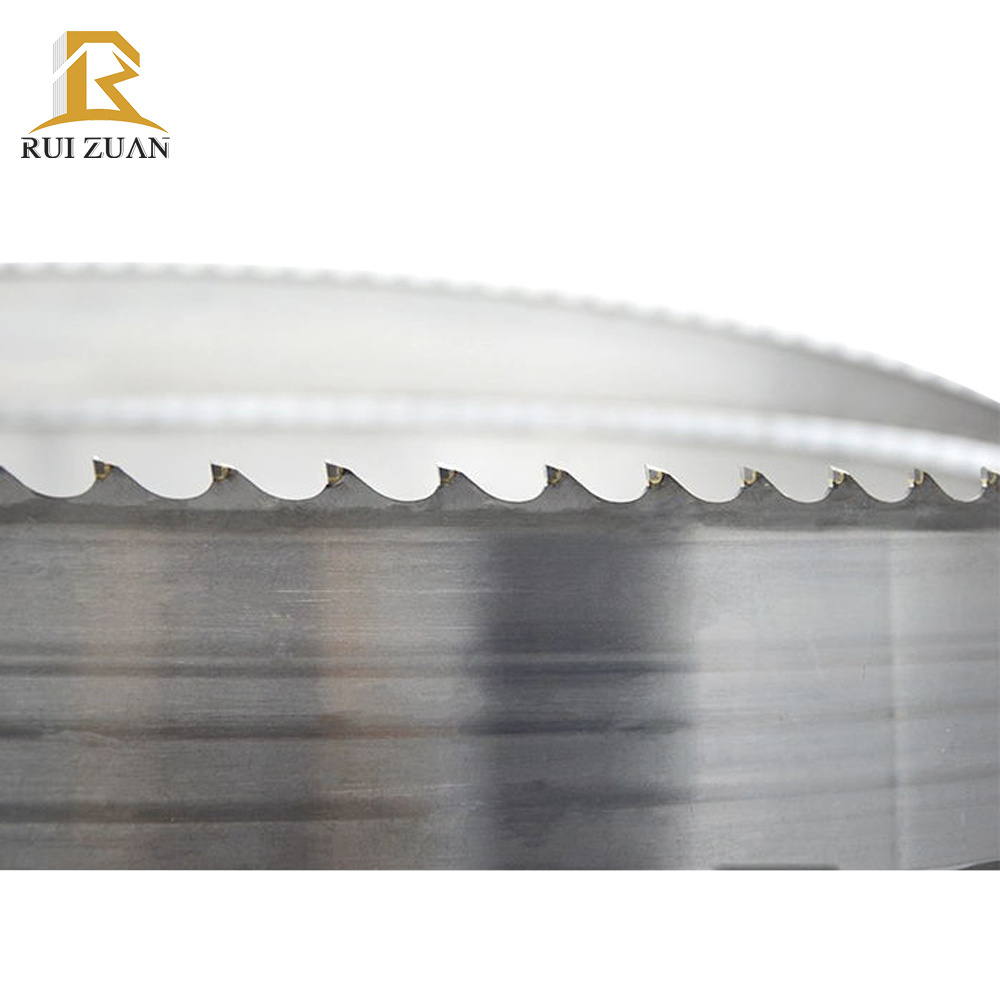

The blades stay sharp throughout a longer life, outlivingtoothed blades by a wide margin. Blades can also bereversed to further extend their life.

2.Cuts tougher:

with stand abuse and give long working life.

3.Cuts smoother:

have thousands of cutting edges and cut with a ‘grinding’ action rather than the aggressive ripping action of toothed blades, reducing the risk of breaking brittle material and leaving the cut edges smooth often requiring no further finishing, and without chipping or damaging the surface.

4.Cuts safer:

Blades cut with minimal vibration and risk of snagging.

5.Cuts better:

Blades cut easily and with little effort. Curves can be cut smoothly and without danger of breakout.

6.Cuts faster:

The cut is faster, more aggressive; control is fine and sure.

7.Cuts more:

Can cut many different ‘problem’ materials.

8.Cuts cheaper:

Long life, high performance and consistent quality,bring a significantly better ROI.

Application

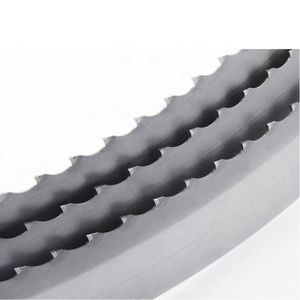

Carbide band saw blades are your solution to cut through materials bi-metal and carbon steel blades just won’t cut. Carbide band saw blades provide high wear resistance and toughness when cutting a variety of applications such as: case hardened steels, spring steels, high speed steels, nickel based alloys, case hardened steels, composite graphite, high nickel alloys, titanium, inconnel, and other exotic metals.

Customer Reviews

|

|

|

|

|

|

Why Choose Us

International Leading Trade Fair

for Grinding Technology

Hot Searches