- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

7kw

-

Weight (KG):

-

9500 kg

-

Name:

-

Hot Press Mahcine

-

Working methods:

-

Fully Automatic

-

Application:

-

Furniture Maker

-

Pressure:

-

120 Ton

-

Keywords:

-

Thermocompressi-on Bonder

-

Finished products:

-

Wood Veneer Sheet

-

Control type:

-

Button Control

-

Working Principle:

-

High Frequency Heating

Quick Details

-

Place of Origin:

-

China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

4000*1500*2300mm

-

Power (kW):

-

7kw

-

Weight (KG):

-

9500 kg

-

Name:

-

Hot Press Mahcine

-

Working methods:

-

Fully Automatic

-

Application:

-

Furniture Maker

-

Pressure:

-

120 Ton

-

Keywords:

-

Thermocompressi-on Bonder

-

Finished products:

-

Wood Veneer Sheet

-

Control type:

-

Button Control

-

Working Principle:

-

High Frequency Heating

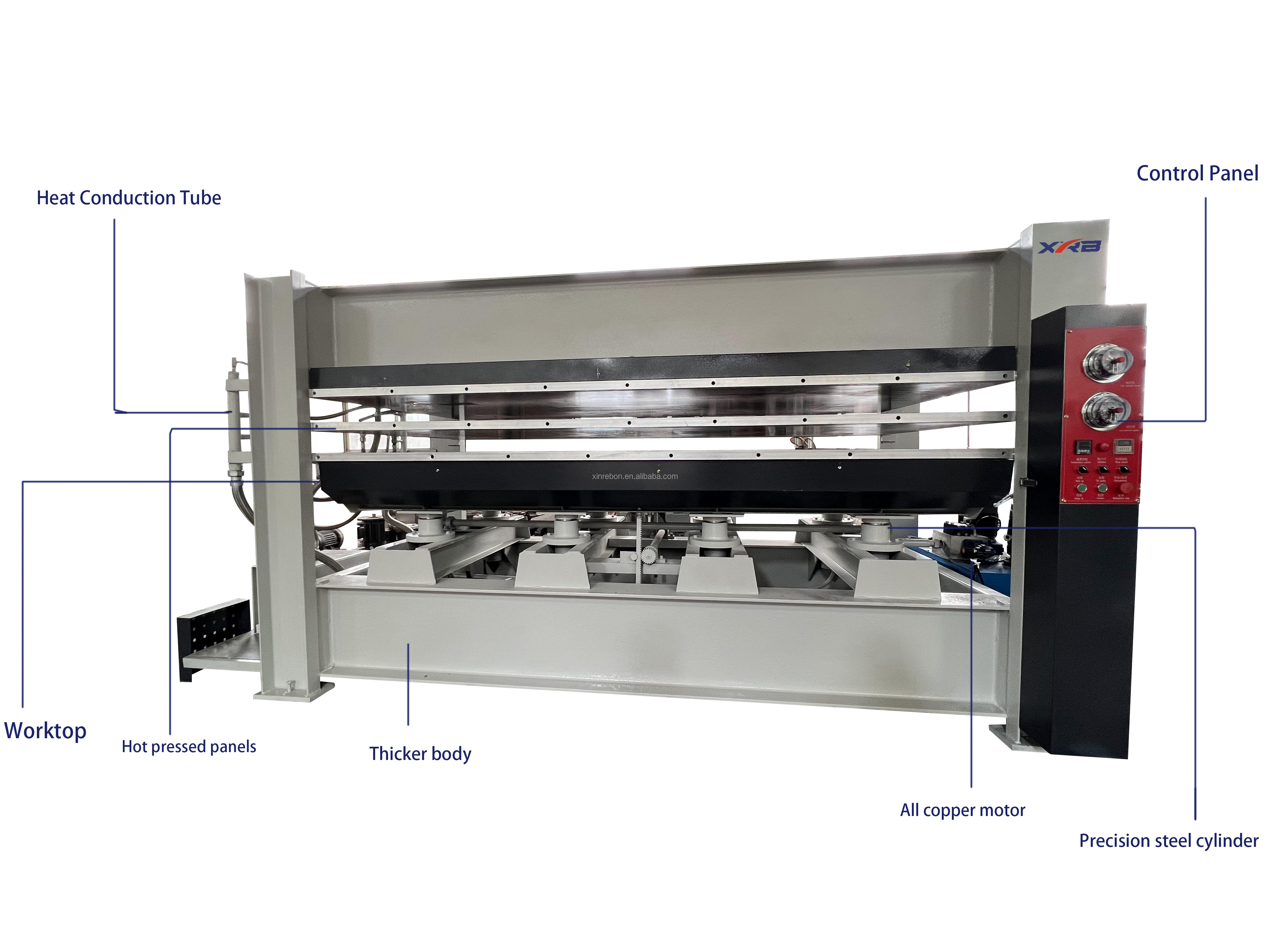

Wood Hot Press Machine

is suitable for furniture production factory, wooden door factory, artificial board of second operation veneering, to hot-pressing bonding panel furniture, building partition wall, wooden door, fireproof door surface materials. In a variety of man-made board, such as: plywood, core-board, MDF, particle board’s surface pressing all kinds of decorative materials, decorative fabric, wood veneer, PVC, etc., It can also be used for veneer drying, leveling, color decoration wood leveling, finalize the design and the effect is remarkable.

|

Model

|

120*3layer

|

120*5layer

|

200*5layer

|

|

Total pressure

|

120

|

120

|

200

|

|

Platen size

|

2500*1300mm(Support)

|

2500*1300mm(Support)

|

2500*1300mm(Support)

|

|

Number of layers

|

3

|

5

|

5

|

|

Number of platens

|

4

|

6

|

6

|

|

Heating power

|

37kw

|

49.5kw

|

90kw

|

|

Pressure pump power

|

7kw

|

7kw

|

7.5lkw

|

|

Max temperature

|

200℃

|

200℃

|

200℃

|

|

Heating media

|

Thermal oil or steam

|

Thermal oil or steam

|

Thermal oil or steam

|

Push-button operation panel, simple operation, equipped with time, temperature control table, always monitor the operation of the machine, a key start, with an emergency stop button switch, high safety performance

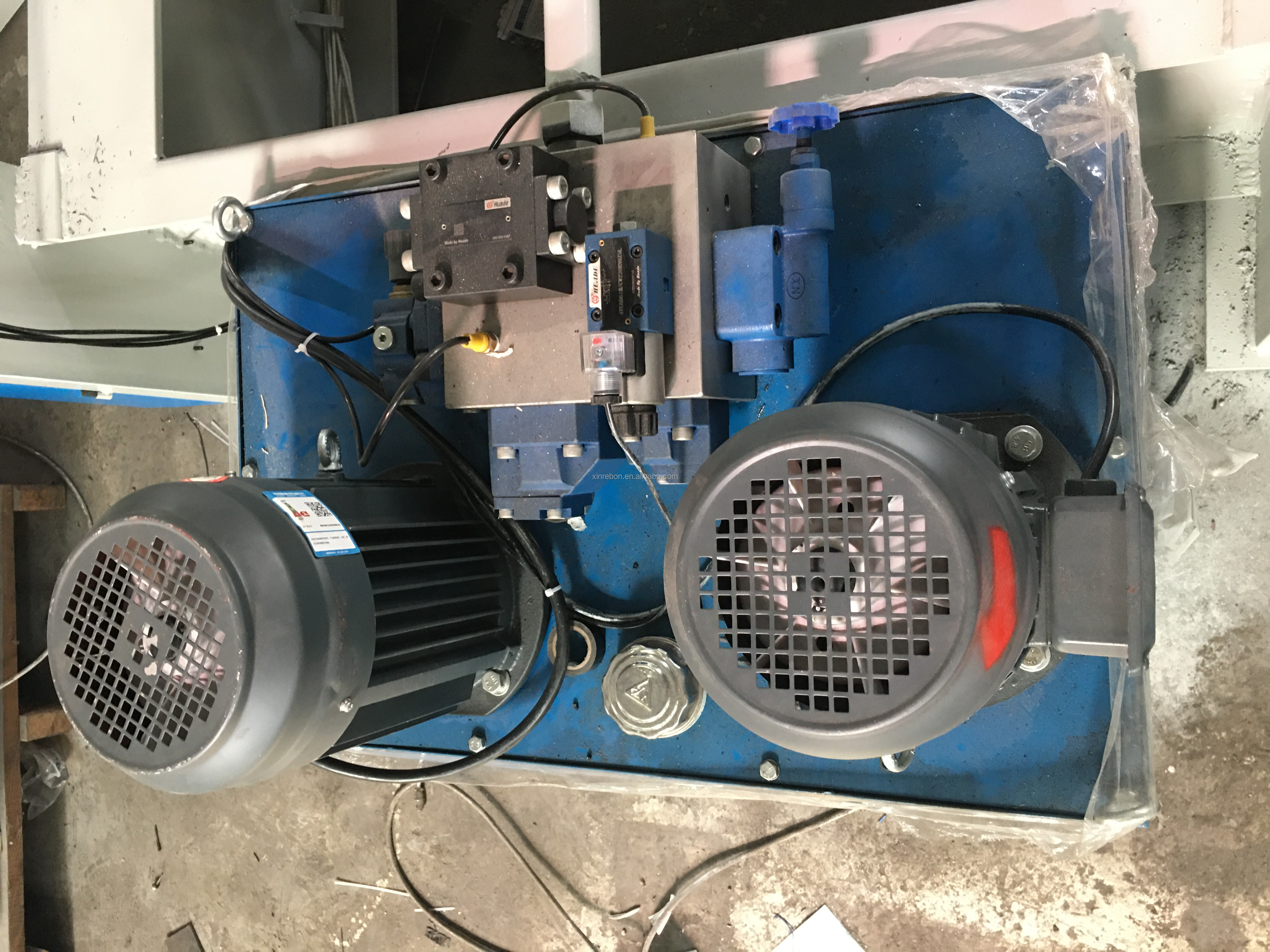

Adopt new integrated hydraulic system with accumulator control system and zero configuration pressure sensor to control the use of pressure; up and down configuration of large-capacity oil tank and new direct-connected liquid filling device; configuration of forced air cooling system to effectively reduce the working temperature of the hydraulic system

THE HOT PRESSIS MAINLY USED TO PRESS VARIOUS DECORATIVE MATERIALS AND MOSAICS ON THE SURFACE OF THE PRE-PRODUCTS.IT CAN ALSO BE USED TO FLATTEN AND DRYVENEERS AND FLATTEN AND SHAPE THE COLORED DECORATIVE WOOD CHIPS

Qingdao XINREBON CNC Technology CO., LTD

XINREBON CNC TECHNOLOGY CO., LTD, we are a professional manufacturing company. The factory is located in Shandong province, 20 km from Qingdao port and only 10 km from the high speed railway station. Based on efficient transportation, our machines can reach consumers directly and easily. We always walk on the road of technological innovation and our products are constantly upgraded. Currently, our machines serve consumers in more than 20 provinces in China and more than 30 countries abroad, enjoying high reputation and acclaim. Combined with years of experience, we have won the trust and praise of our customers.

Now we produce all kinds of woodworking machines, including edge banding machines, cold/hot presses, planers, sanding machines, polishing machines, CNC routers, CNC panel cutting saws, horizontal band saws, multi-row drilling machines, precision push table sawing machines, various solid wood processing machines, etc.

Our philosophy: professional, efficient and loyal, our mission: to create core value for our customers, our employees and our company.

(1) Pre-sale services:

* Provide the free consultation of the equipment .

* Provide the standard device and the flow chart.

* According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

* Welcome to visit our factory.

(2)Services during the sales:

* Inspect the machine before leaving the factory.

* Oversea install and debug the equipment.

* Train the first-line operator.

(3)After sale services:

* 24 hours online service.

* Provide the VIDEO with Install and debug the equipment.

* Provide technical exchanging.

* Provide the free consultation of the equipment .

* Provide the standard device and the flow chart.

* According to the clients’ special requirement, offering the reasonable plan and free design helping to

select the equipment.

* Welcome to visit our factory.

(2)Services during the sales:

* Inspect the machine before leaving the factory.

* Oversea install and debug the equipment.

* Train the first-line operator.

(3)After sale services:

* 24 hours online service.

* Provide the VIDEO with Install and debug the equipment.

* Provide technical exchanging.

Hot Searches