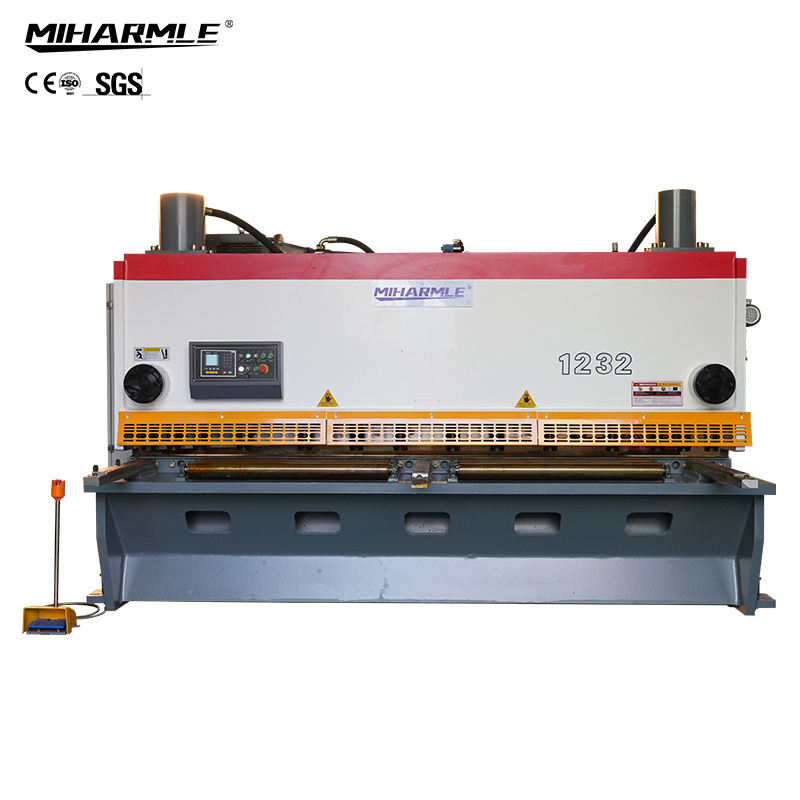

- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

2000 mm

-

Backgauge Travel (mm):

-

0 - 500 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

Miharmle

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

4000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2200*1100*1200mm

-

Year:

-

2023

-

Marketing Type:

-

New Product 2022

-

Machine Type:

-

shearing machine

-

Application:

-

Metal Sheet cutting

-

Usage:

-

Pressing Metal Products

-

Color:

-

Customized

-

Power:

-

5.5kw

-

Main Motor:

-

Siemens Germany

-

Hydraulic System:

-

Bosch Rexroth Germany

-

Electrical components:

-

Schneider

-

Cutting thickness:

-

3mm

-

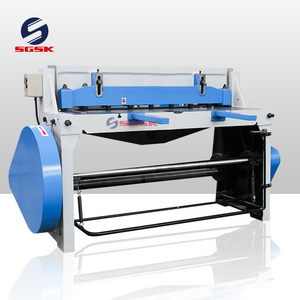

Cutting mode:

-

Electric Sheaing Machine

Quick Details

-

Max. Cutting Width (mm):

-

2000

-

Max. Cutting Thickness (mm):

-

3 mm

-

Shearing Angle:

-

2

-

Blade Length (mm):

-

2000 mm

-

Backgauge Travel (mm):

-

0 - 500 mm

-

Throat Depth (mm):

-

120 mm

-

Brand Name:

-

Miharmle

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

4000 KG

-

Place of Origin:

-

Anhui, China

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

2200*1100*1200mm

-

Year:

-

2023

-

Marketing Type:

-

New Product 2022

-

Machine Type:

-

shearing machine

-

Application:

-

Metal Sheet cutting

-

Usage:

-

Pressing Metal Products

-

Color:

-

Customized

-

Power:

-

5.5kw

-

Main Motor:

-

Siemens Germany

-

Hydraulic System:

-

Bosch Rexroth Germany

-

Electrical components:

-

Schneider

-

Cutting thickness:

-

3mm

-

Cutting mode:

-

Electric Sheaing Machine

FEATURES

* THE MACHINE USES STEEL PLATE WELDED STRUCTURE, THE FUSELAGE USING THE FINITE ELEMENT ANALYSIS AND DESIGN, VIBRATION TO ELIMINATE

STRESS OF AGING, SO THAT BODY STABLE AND RELIABLE

* USING THREE-POINT ROLLING GUIDE PULLEY CAN ELIMINATE THE SUPPORT GAP, AND INCREASE CUTTING PRECISION

* SHEARING ANGLE CAN BE ADJUSTED WITHIN A CERTAIN RANGE, WHICH CAN REDUCE THE SHEARING DEFORMATION OF SHEET METAL AND CAN SHEAR

MUCH THICKER SHEET METAL

* THE SHEARING STROKE CAN BE ADJUSTED AT WILL, WHICH RAISE THE WORKING EFFICIENCY AND REALIZE THE FUNCTION OF PARTITION CUTTING

* THE BACKGAUGE IS DESIGNED MANUAL LIFTING FUNCTION, WHICH IS CONVENIENT TO SHEAR LONG SHEET METAL

* INSIDE THE WALLBOAED MANUAL PERTOL PUMP IS INSTALLED, WHICH MAKES OPERATING CONVENIENT AND LUBRICATING RELIABLE

* PLUG IN HYDRAULIC SYSTEM CAN MAKE OIL TEMPERATURE BECOME HIGH SLOWLY, MEANWHILE IT ENHANCE THE RELIABILITY AND SAFETY

OPERATION OF MACHINE

* DAC310 AND DAC360 CNC CONTROLLERS BOTH ARE AVAILBLE UPON REQUEST

* THE MACHINE USES STEEL PLATE WELDED STRUCTURE, THE FUSELAGE USING THE FINITE ELEMENT ANALYSIS AND DESIGN, VIBRATION TO ELIMINATE

STRESS OF AGING, SO THAT BODY STABLE AND RELIABLE

* USING THREE-POINT ROLLING GUIDE PULLEY CAN ELIMINATE THE SUPPORT GAP, AND INCREASE CUTTING PRECISION

* SHEARING ANGLE CAN BE ADJUSTED WITHIN A CERTAIN RANGE, WHICH CAN REDUCE THE SHEARING DEFORMATION OF SHEET METAL AND CAN SHEAR

MUCH THICKER SHEET METAL

* THE SHEARING STROKE CAN BE ADJUSTED AT WILL, WHICH RAISE THE WORKING EFFICIENCY AND REALIZE THE FUNCTION OF PARTITION CUTTING

* THE BACKGAUGE IS DESIGNED MANUAL LIFTING FUNCTION, WHICH IS CONVENIENT TO SHEAR LONG SHEET METAL

* INSIDE THE WALLBOAED MANUAL PERTOL PUMP IS INSTALLED, WHICH MAKES OPERATING CONVENIENT AND LUBRICATING RELIABLE

* PLUG IN HYDRAULIC SYSTEM CAN MAKE OIL TEMPERATURE BECOME HIGH SLOWLY, MEANWHILE IT ENHANCE THE RELIABILITY AND SAFETY

OPERATION OF MACHINE

* DAC310 AND DAC360 CNC CONTROLLERS BOTH ARE AVAILBLE UPON REQUEST

Details Images

1. E21S Controller

2. France Schneider Electric

Use France Schneider Electric to ensure machine stability,high quality electric parts can perform well even the electricity is not

stable and customs can easily get the replacement anywhere in the world

3. Siemens Main Motor

German famous brand motor improves the lifespan of the machine and keeps the machine working in low noise environment

4. Blade Gap Adjustment

Adjust the cutting blades gap by motor according the cutting thickness of the metal sheet can get better cutting performance

5. Workingbeach Rolling Steel Ball

Rolling steel ball of workbench can reduce friction,protect the workpiece surface;delicate design is convenient for cutting petty

materials by hand

6. Verticality Regulator and Front Positioning Device

Setting verticality and positioning device on the left-most front supporter,guaranteeing the cutting precision,easy

operation,practical and efficient

7. Alloy Tool Steel

Made by high quality alloy tool steel,the machine can meet the impacting load and high wear resistance requirements when working

8. Pedal Switch

Enhancing the service life and operational sensitivity and never broken up

2. France Schneider Electric

Use France Schneider Electric to ensure machine stability,high quality electric parts can perform well even the electricity is not

stable and customs can easily get the replacement anywhere in the world

3. Siemens Main Motor

German famous brand motor improves the lifespan of the machine and keeps the machine working in low noise environment

4. Blade Gap Adjustment

Adjust the cutting blades gap by motor according the cutting thickness of the metal sheet can get better cutting performance

5. Workingbeach Rolling Steel Ball

Rolling steel ball of workbench can reduce friction,protect the workpiece surface;delicate design is convenient for cutting petty

materials by hand

6. Verticality Regulator and Front Positioning Device

Setting verticality and positioning device on the left-most front supporter,guaranteeing the cutting precision,easy

operation,practical and efficient

7. Alloy Tool Steel

Made by high quality alloy tool steel,the machine can meet the impacting load and high wear resistance requirements when working

8. Pedal Switch

Enhancing the service life and operational sensitivity and never broken up

|

model

|

cutting thickness (mm)

|

cutting width (mm)

|

throat depth

(mm) |

ctting angle

|

backgauge range(mm)

|

stroke number(times/min)

|

main motor power (kw)

|

outline size (LXWXH in mm)

|

|

QC11Y-6X2500

|

6

|

2500

|

100

|

0.5°- 1°30'

|

20-600

|

≥12

|

7.5

|

3100x1725x1960

|

|

QC11Y-6X3200

|

6

|

3200

|

100

|

0.5°- 1°30'

|

20-600

|

≥12

|

7.5

|

3935x1840x1995

|

|

QC11Y-6X4000

|

6

|

4000

|

100

|

0.5°- 1°30'

|

20-600

|

≥10

|

7.5

|

4650x1840x2100

|

|

QC11Y-6X5000

|

6

|

5000

|

100

|

0.5°- 1°30'

|

20-600

|

≥7

|

7.5

|

5700x1950x2380

|

|

QC11Y-6X6000

|

6

|

6000

|

100

|

0.5°- 1°30'

|

20-600

|

≥6

|

11

|

6650x1985x2380

|

|

QC11Y-8X2500

|

8

|

2500

|

100

|

0.5°- 2°

|

20-600

|

≥11

|

11

|

3135x1840x2075

|

|

QC11Y-8X3200

|

8

|

3200

|

100

|

0.5°- 2°

|

20-600

|

≥10

|

11

|

3850x1890x2050

|

|

QC11Y-8X4000

|

8

|

4000

|

100

|

0.5°- 2°

|

20-600

|

≥8

|

11

|

4650x1990x2075

|

|

QC11Y-8X5000

|

8

|

5000

|

100

|

0.5°- 2°

|

20-800

|

≥7

|

11

|

5650x2050x2400

|

|

QC11Y-8X6000

|

8

|

6000

|

100

|

0.5°- 2°

|

20-800

|

≥6

|

18.5

|

6805x2115x2715

|

|

QC11Y-12X2500

|

12

|

2500

|

150

|

0.5°- 2°30'

|

20-800

|

≥6

|

18.5

|

3195x1950x2210

|

|

QC11Y-12X3200

|

12

|

3200

|

150

|

0.5°- 2°30'

|

20-800

|

≥5

|

18.5

|

3895x1950x2240

|

|

QC11Y-12X4000

|

12

|

4000

|

150

|

0.5°- 2°30'

|

20-800

|

≥6

|

18.5

|

4710x2000x2485

|

|

QC11Y-12X6000

|

12

|

6000

|

150

|

0.5°- 2°30'

|

20-1000

|

≥5

|

18.5

|

7150x2300x3100

|

|

QC11Y-16X2500

|

16

|

2500

|

150

|

0.5°- 2°30'

|

20-800

|

≥6

|

18.5

|

3215x1970x2340

|

|

QC11Y-16X3200

|

16

|

3200

|

150

|

0.5°- 2°30'

|

20-800

|

≥5

|

18.5

|

3915x1970x2455

|

|

QC11Y-16X4000

|

16

|

4000

|

150

|

0.5°- 2°30'

|

20-800

|

≥5

|

22

|

4715x2010x2590

|

|

QC11Y-16X5000

|

16

|

5000

|

150

|

0.5°- 3°

|

20-1000

|

≥5

|

22

|

6000x2300x3000

|

|

QC11Y-16X6000

|

16

|

6000

|

150

|

0.5°- 3°

|

20-1000

|

≥4

|

30

|

7250x2400x3100

|

|

QC11Y-20X2500

|

20

|

2500

|

150

|

0.5°- 3°

|

20-800

|

≥6

|

30

|

3235x2020x2645

|

|

QC11Y-20X3200

|

20

|

3200

|

150

|

0.5°- 3°

|

20-800

|

≥5

|

30

|

4150x2100x2755

|

|

QC11Y-20X4000

|

20

|

4000

|

150

|

0.5°- 3°

|

20-800

|

≥4

|

37

|

4955x2200x2885

|

Our Workshop

Hot Searches