- Product Details

- {{item.text}}

Quick Details

-

Mould life:

-

100,000

-

Cavity:

-

1 Cavity

-

Surface treatment:

-

Polishing

-

Runner:

-

Hot Runner\ Cold Runner

-

Design software:

-

UG,PRO-E,CAD

-

Color:

-

Customized

-

Package:

-

Wooden Case

-

Mould base:

-

LKM,HASCO,DME

Quick Details

-

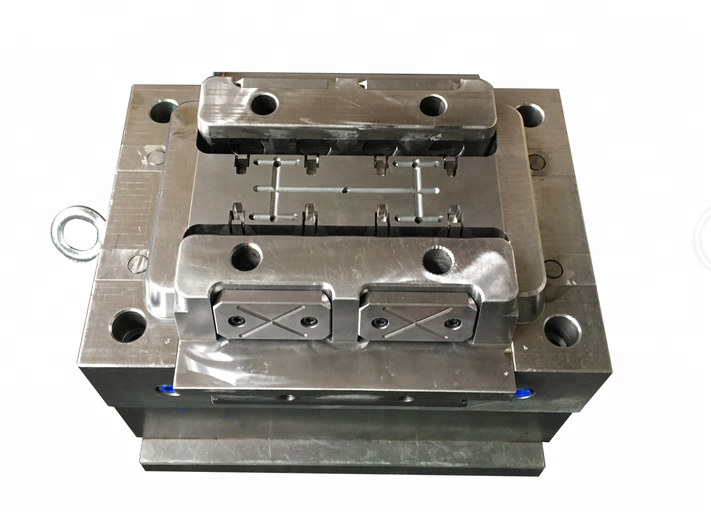

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Zhejiang, China

-

Material:

-

steel

-

Mould life:

-

100,000

-

Cavity:

-

1 Cavity

-

Surface treatment:

-

Polishing

-

Runner:

-

Hot Runner\ Cold Runner

-

Design software:

-

UG,PRO-E,CAD

-

Color:

-

Customized

-

Package:

-

Wooden Case

-

Mould base:

-

LKM,HASCO,DME

COMPANY INTRODUCTION

————————————————————————————————————

Jingsen Mould Company located in "the hometown of moulds"——Huangyan, Taizhou, Zhejiang, China.

We are specialized in designing & manufacturing plastic injection & blowing moulds for over 6 years since we established.

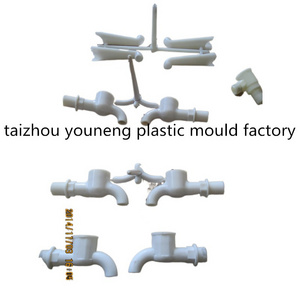

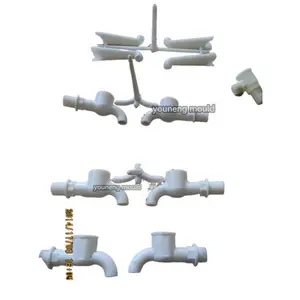

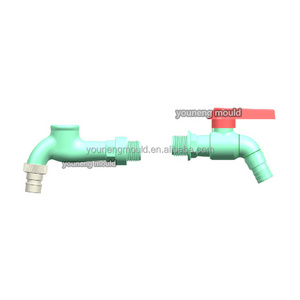

Scope of injection mould: including commodity, household appliances, vehicle, baby products, garden products & customized parts.

L ongstanding business relations: USA, Britain, Argentina, Russia, Egypt, Dubai, Spain, Syria, Italy, Korea, Thailand, Vietnam, Brazil, Slovakia, Columbia, Lebanon, Turkey, Pakistan and so on.

mould companies

————————————————————————————————————

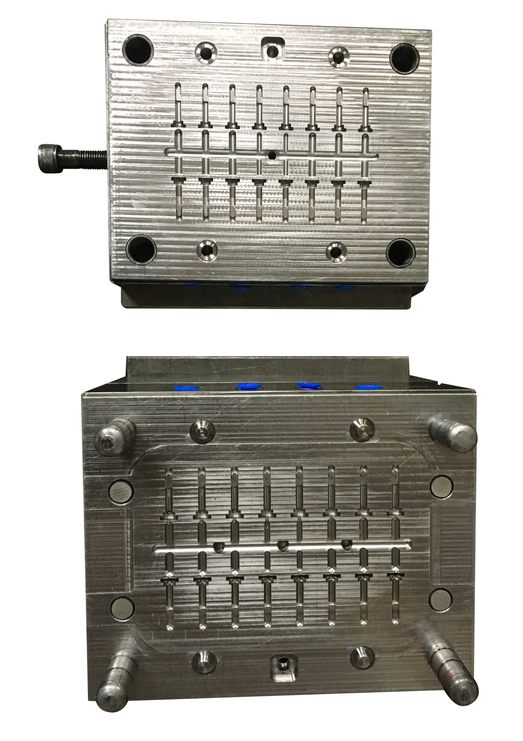

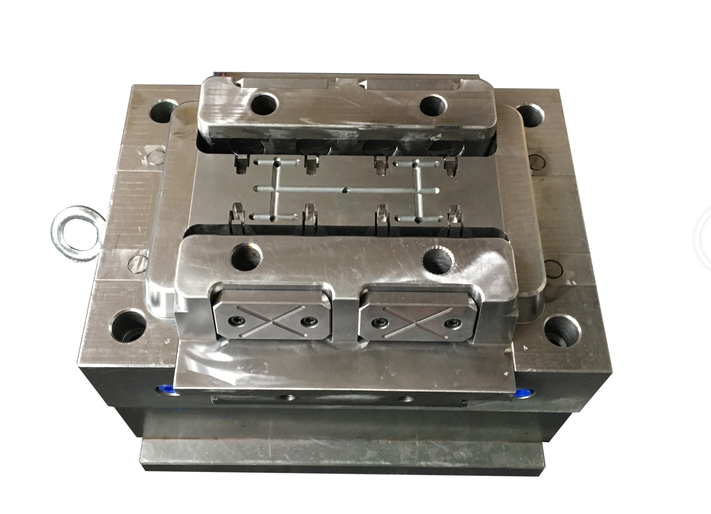

Please take following mould essential informations for your reference:

| Main Technique Parameters | |

|

Cavity/Core

Material |

718H, P20, NAK80, 2316, 2738, 2344 |

| Product Material | ABS, PPR, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone, PA, PBT, PEI, etc. |

| Base | LKM or by requested |

| Structure | Double color injection mould, Solid Mould, Insert Mould, Mould with Slide, Mould with Lifter |

| Runner System | Hot runner, Cold runner |

| Cavity | Single cavity, multi cavities by requested (support similar products in one mould) |

| Finish | Corrosion word, Mirror finish, Brushed |

| Longevity | Available SHOTS will depend on the steel material you choose |

| Mould standard | HASCO, DME, MISUMI, or by requested etc. |

| Software | CAD, Pro-E, UG, etc |

| Design Time | 3-7 days after we receive your samples or your drawings |

| Main Technique | Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, etc. |

| Production time | 1-3 months, depends on mould structure |

| Packing | Wooden case, or by request |

mould companies / SAMPLE PHOTOS ————————————————————————————————————

THE FLOW CHART TO PLACE AN ORDER

————————————————————————————————————

|

Receive inquiries from customers |

|

We will send you quotation within 24 hours after inquiries confirmed |

|

Customers need to offer samples or 2D/3D drawings and some details about the mould |

|

Confirm the order (quality , price , material , delivery time , payment terms etc.) |

|

According to your requirement to prepare the production |

|

Clients confirm the details of the mould |

|

Surface shaping |

|

Drill holes , high speed carve machine ,wire cutting , EDM, etc. |

|

Arranging the test mould and sending the samples to customers |

|

If customers do not satisfy the samples, please give us advice to repair |

|

Repair , Polish , Texture |

|

We will send samples to customers for confirming |

|

Delivery by sea or by air ,etc |

WHY CHOOSE US JINGSEN MOULD

————————————————————————————————————

Below are just a few reasons to do business with Jingsen:

- Sufficient experience in plastic mold design and manufacture

- Outstanding teamwork

- Constant technical innovation

- High-quality, low-cost, trouble-free molds

- Attentive after-sales services

SHIPMENT PACKING

————————————————————————————————————

CONTACT US

————————————————————————————————————

HUANGYAN, CHINA

West Industry Zone, Huangyan, Taizhou, Zhejiang, China 318020

WEBSITE:

www.china-jingsen.com