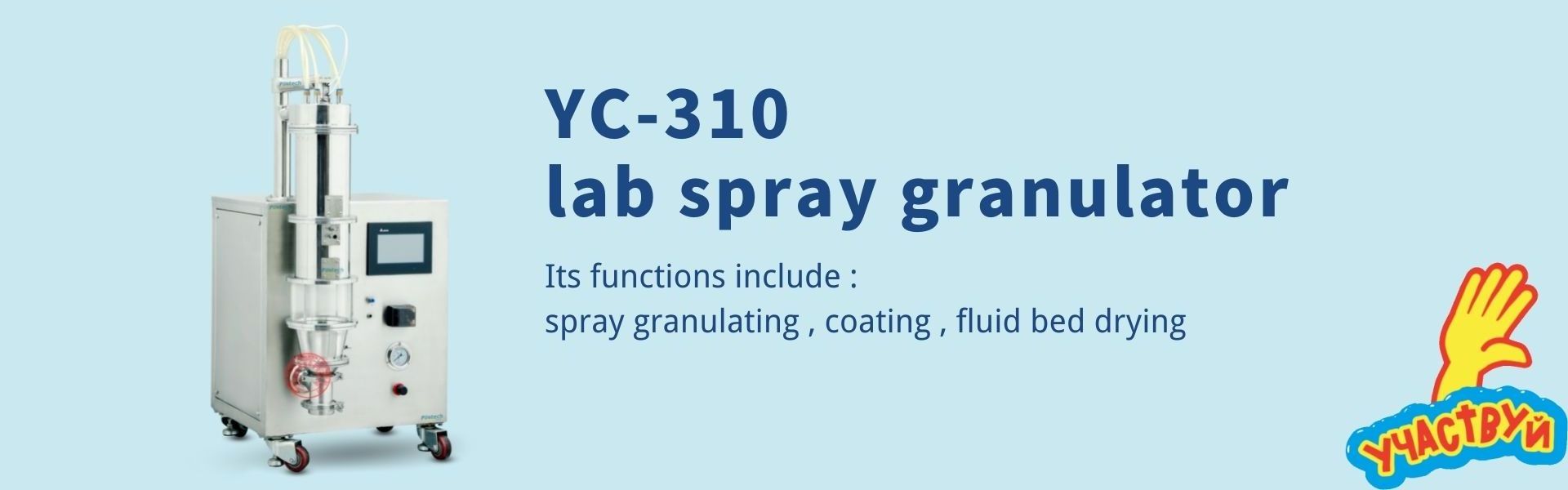

Name: Drying Chamber

M aterial: SUS304 stainless steel , high borosilicate glass

The orgnization of thsese materials is helpful for oper-ators to observe the drying dynamics . The stainless steel is unbreakable and heat-resisting.