- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XF

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1250*1000*1220

-

Weight:

-

200 KG

-

Product name:

-

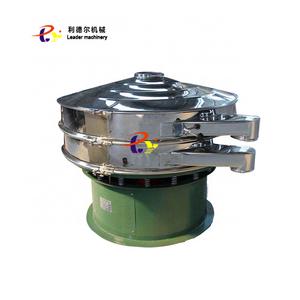

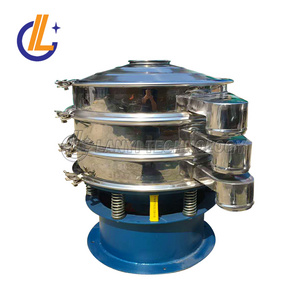

60um mesh fine powder screen ultrasonic rotary vibrating sieve machine

-

Keyword:

-

Ultrasonic rotary vibrating screen sieve machine

-

Layer(s):

-

1-5 Layers

-

Capacity:

-

0.05-5t/h

-

Usage:

-

Powder Screening

-

Function:

-

Screening\separation\sorting\sieving

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

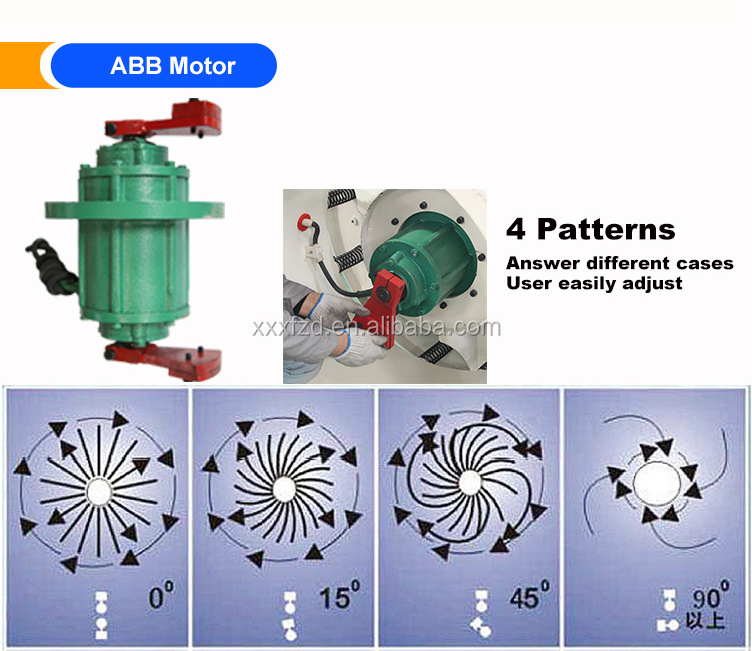

Motor:

-

Vertical Vibrating Motor

-

Frequency:

-

1440rpm

-

Cleaning system:

-

Ultrasonic Cleaning System

Quick Details

-

Type:

-

Circular

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XF

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

1250*1000*1220

-

Weight:

-

200 KG

-

Product name:

-

60um mesh fine powder screen ultrasonic rotary vibrating sieve machine

-

Keyword:

-

Ultrasonic rotary vibrating screen sieve machine

-

Layer(s):

-

1-5 Layers

-

Capacity:

-

0.05-5t/h

-

Usage:

-

Powder Screening

-

Function:

-

Screening\separation\sorting\sieving

-

Material:

-

Carbon Steel/Stainless Steel 304/316L

-

Motor:

-

Vertical Vibrating Motor

-

Frequency:

-

1440rpm

-

Cleaning system:

-

Ultrasonic Cleaning System

XFC ultrasonic vibrating screen attached to the screen on the ultrasonic vibration wave (mechanical wave), makes the ultra micro powder accept huge ultrasonic acceleration, thus inhibiting adhesion, friction, flat, wedging screen blocking factors, such as can obviously improve the screening efficiency and network efficiency.

| Technical Parameter | |||||

| Model | Screen surface diameter(mm) | Effective screening area(m 2 ) | Screen mesh | Layer |

Power(kw)

|

| XFC-600 | Φ560 | 0.2289 |

20-800 |

1-5 | 0.25-0.55 |

| XFC-800 | Φ760 | 0.4183 | 0.55-0.75 | ||

| XFC-1000 | Φ930 | 0.6359 | 0.75-1.1 | ||

| XFC-1200 | Φ1130 | 0.9499 | 1.1-1.5 | ||

| XFC-1500 | Φ1430 | 1.5386 | 1.5-3 | ||

| XFC-1800 | Φ1730 | 2.2687 | 3-4.5 | ||

Food industry:

sugar, spices, starch, soybeans, salt, instant potatoes, animal feed, powdered milk, cereals and grains, tobacco, teff, instant coffee granules, chocolate powder, soybean flour, broth concentrate, potato granules, sugar beets, ice cream, fruit juices, vegetable and pickle canneries, soybean oil.

Construction industry:

sand, glass beads, plaster, abrasives Grit/shot, borax.

Chemical industry:

fertilizer, rubber, polystyrene beads, paint, detergents, latex, catalyst, casein.

Recycle:

animal blood, paper effluent, brewer yeast, sewage, manure, brewery waste, laundry waste, potato peelings and waste, tallow.

1.How to find suitable model?

Let us know below details:

a.Required capacity, e.g. 200kg/hour.

b.Layers of screens, e.g. 2 layers.

c.Screen mesh size, or particle size. e.g. 1mm or 20 mesh.

d.Material name, water content ratio. e.g. dried flour powder.

e.Other special requirement.

2.Warranty:

You have 12 month guarantee, we provide 100% original spare parts and

online support if any breakdown in warranty period.

3.Price security:

We stand 50% of the floating cost if exchange rate changes before delivery.

4.How to ensure the machine work good with my material?

We can test your material in the machine and let you see process in video.