- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2300*1200*2000mm

-

Weight:

-

600kg

-

Output product name:

-

potato chips

-

Application:

-

Vegetable processing plant, Snack food factory, Frozen food

-

Material:

-

food grade 304 Stainless Stee

-

Temperature range:

-

0-300℃

-

Product name:

-

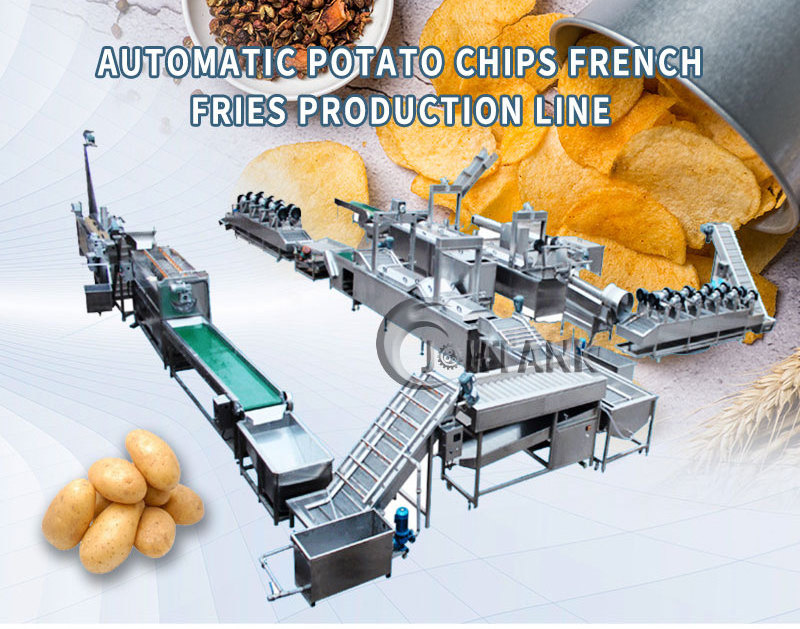

potato frozen fries process equipment

-

Production Capacity:

-

50kg/h-300kg/h

-

Heating method:

-

electric heating, gas heating and diesel heating

-

Package:

-

Container or wooden package

-

Processing Types:

-

full automatic and semi automatic

-

After-sales Service:

-

rovided: Field installation, commissioning and training

-

Finished Products:

-

French Fries/ potato chips

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Peru, Chile, Colombia

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

220V/380V

-

Power:

-

47kw

-

Dimension(L*W*H):

-

2300*1200*2000mm

-

Weight:

-

600kg

-

Output product name:

-

potato chips

-

Application:

-

Vegetable processing plant, Snack food factory, Frozen food

-

Material:

-

food grade 304 Stainless Stee

-

Temperature range:

-

0-300℃

-

Product name:

-

potato frozen fries process equipment

-

Production Capacity:

-

50kg/h-300kg/h

-

Heating method:

-

electric heating, gas heating and diesel heating

-

Package:

-

Container or wooden package

-

Processing Types:

-

full automatic and semi automatic

-

After-sales Service:

-

rovided: Field installation, commissioning and training

-

Finished Products:

-

French Fries/ potato chips

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Peru, Chile, Colombia

-

After-sales Service Provided:

-

Free spare parts

-

Certification:

-

CE

Product Description

Specification

|

Product name

|

french fries processing plant

|

|

10Production Capacity

|

100kg/h-1000kg/h

|

|

Heating Method

|

Coal, electricity, gas, diesel

|

|

Material

|

food grade 304 Stainless Steel

|

|

Power

|

47KW

|

|

final produce

|

french fries and potato chips/crisps

|

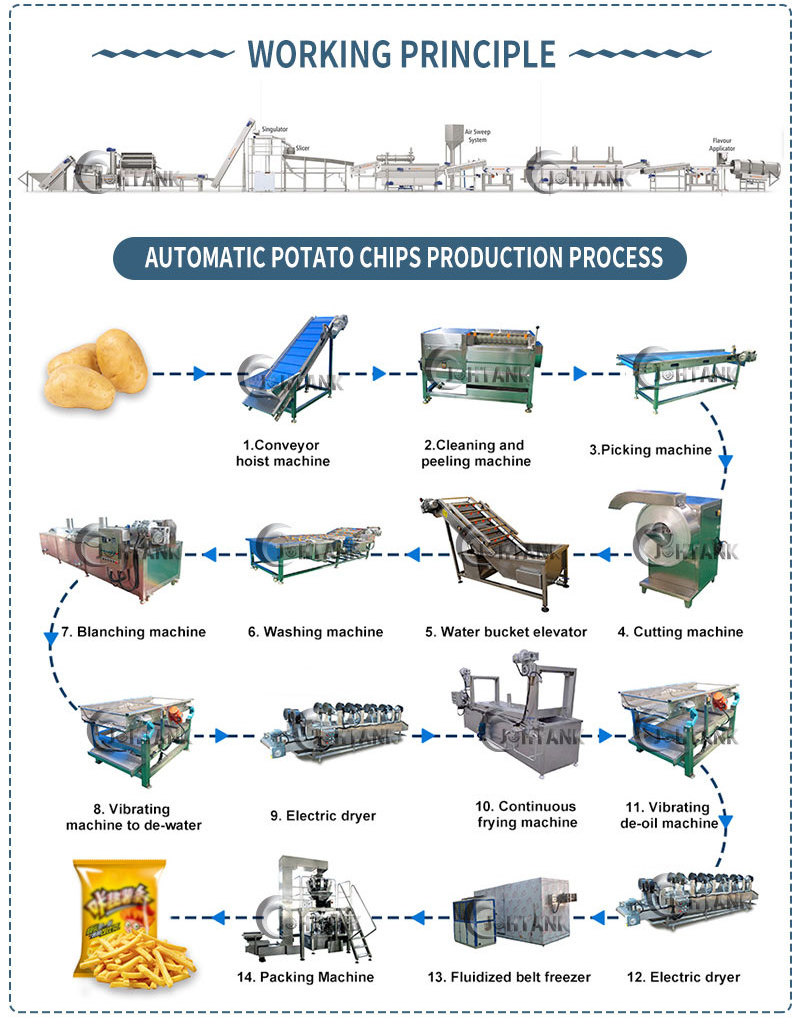

Production process

Product Details

Fresh potato elevator

Elevator conveyor,

transports the chips or fries to the fryer

Full automatic semi-automatic frozen french fries machine potato chips crisp production line

Potato washing and peeling machine

1. brush and corundum rollers to peel the potatoes thtoughtly

2. Spraying system to clean the potatoes

3. Spiral design to make sure automatic discharging

2. Spraying system to clean the potatoes

3. Spiral design to make sure automatic discharging

The picking line

1. Manually pick up the defective potatoes

2. Conveying speed adjustable

2. Conveying speed adjustable

Potato chips cutting machine

1. Cut the potato into chips

2. High efficiency, easy to opetate

3. Cutting surface is smooth, without demage

4. Chips size is adjustable from 7*7mm to 12*12mm

2. High efficiency, easy to opetate

3. Cutting surface is smooth, without demage

4. Chips size is adjustable from 7*7mm to 12*12mm

Bubble washing machine

1. remove the starch from the potato chips

2. Strong water flow, bubble impact

3. High pressure spraying system

4. Filter system and water recycling system

2. Strong water flow, bubble impact

3. High pressure spraying system

4. Filter system and water recycling system

The blanching machine

1. Inhibits enzyme activity

2. Color protection of the potato chips

3. Make the chips 70%-80% ripening

2. Color protection of the potato chips

3. Make the chips 70%-80% ripening

The air drying machine

1. Use after blanching for drying the surface of the blanched chips, get ready for next step frying

2. Also use after frying for pre-cooling and de-oiling the fried chips, keep the good taste

2. Also use after frying for pre-cooling and de-oiling the fried chips, keep the good taste

The frying machine

1. Automatic lifting system, easy to clean

2. Double mesh belt transmission to avoid the chips floating

3. Oil filter and recycling system to automatically and continuously filter teh oil residue to extend the service life

4. Electric or gas heating

2. Double mesh belt transmission to avoid the chips floating

3. Oil filter and recycling system to automatically and continuously filter teh oil residue to extend the service life

4. Electric or gas heating

Vibrating de-oiling machine

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

The seasoning machine

1. With spice tank, the flow of spice adjustable

2. Rotary drum style and octangle style available

2. Rotary drum style and octangle style available

The freezing machine

Frozen zone within the frame structure, support, air duct plate, mesh belt, big water pans,guide rail and other parts adopt food-grade wire drawing of stainless steel 304 (except for motor and reducer) easy to clean,achieve the HACCP requirements.

The packing machine

1. Tow kinds package machine available: vacuum packing machine, weighing and packing machine

2. The weighing and packing machine can automatically loading, weighing, filling, sealing, cutting, printing and conveying.

2. The weighing and packing machine can automatically loading, weighing, filling, sealing, cutting, printing and conveying.

Hot Searches