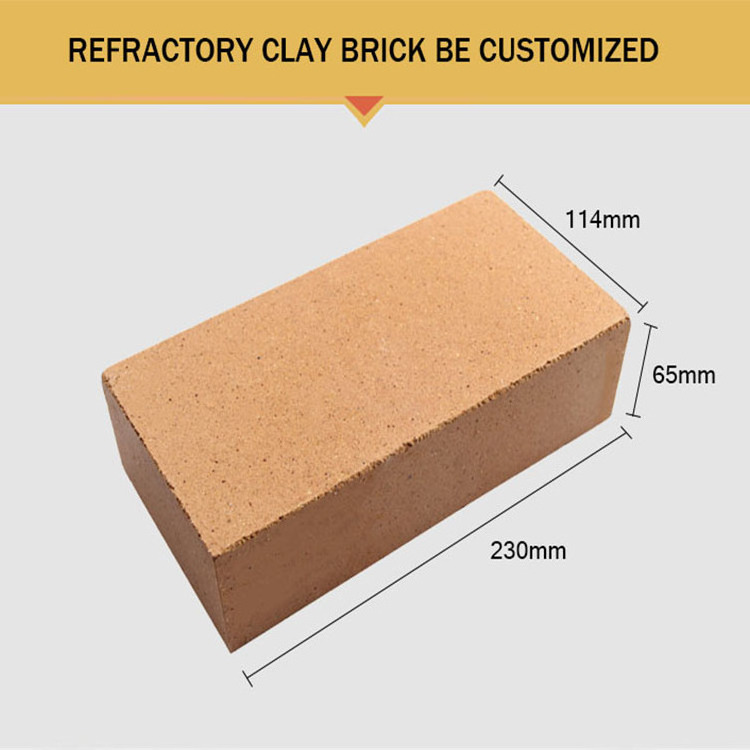

- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

0.5

-

CrO Content (%):

-

--

-

SiC Content (%):

-

--

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK32

-

Brand Name:

-

LKT

-

Bulk Density(kg/m3):

-

2100-2200

-

Apparent porosity(%):

-

22-24

-

Fe2O3(%):

-

2

-

Na2O(%):

-

0.6

-

TiO2(%):

-

3

-

Na2O+K2O+Li2O(%):

-

0.5

-

Pyrometric Cone Equivalent Orton Cone:

-

31-32

-

Cold Crushing Strength (MPa):

-

22-32

-

Modulus of Rupture (kg/cm2):

-

55-70

Quick Details

-

SiO2 Content (%):

-

57.8

-

Al2O3 Content (%):

-

36.2

-

MgO Content (%):

-

--

-

CaO Content (%):

-

0.5

-

CrO Content (%):

-

--

-

SiC Content (%):

-

--

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

SK32

-

Brand Name:

-

LKT

-

Bulk Density(kg/m3):

-

2100-2200

-

Apparent porosity(%):

-

22-24

-

Fe2O3(%):

-

2

-

Na2O(%):

-

0.6

-

TiO2(%):

-

3

-

Na2O+K2O+Li2O(%):

-

0.5

-

Pyrometric Cone Equivalent Orton Cone:

-

31-32

-

Cold Crushing Strength (MPa):

-

22-32

-

Modulus of Rupture (kg/cm2):

-

55-70

|

Material

|

|

Common

|

|

||

|

Item

|

|

SK32

|

SK34

|

||

|

Pyrometric Cone Equivalent Orton cone

|

|

31-32

|

33-34

|

||

|

Refractoriness (℃)

|

|

1715

|

1760

|

||

|

Bulk Density (kg/m3)

|

|

2100-2200

|

2200-2250

|

||

|

Apparent Porosity (%)

|

|

22-24

|

18-20

|

||

|

Cold Crushing Strength (MPa)

|

|

22-32

|

30-35

|

||

|

Modulus of Rupture (kg/cm2)

|

|

55-70

|

60-80

|

||

|

Reheat test,permanent linearchange after heating at

|

(1400℃%)

|

0.0-0.2

|

-0.18

|

||

|

SiO2 (%)

|

|

57.8

|

52.4

|

||

|

Al2O3 (%)

|

|

36.2

|

42.1

|

||

|

Fe2O3 (%)

|

|

2

|

1.4

|

||

|

Cao (%)

|

|

0.5

|

0.4

|

||

|

Na2O+K2O+Li2O (%)

|

|

0.5

|

0.5

|

||

|

Material

|

|

Special

|

|

|

|

|

|

|

|||||||

|

Item

|

SK34

|

Blast furnace

|

|

Hot blast stove

|

|

|

Glass Furnace

|

|

|||||||

|

|

|

ZGN-42

|

GN-42

|

RN-42

|

RN-40

|

RN-36

|

BN-40a

|

BN-40b

|

|||||||

|

Refractoriness (℃)

|

1760

|

1760

|

1760

|

1760

|

1740

|

1700

|

-

|

-

|

|||||||

|

Bulk Density (kg/m3)

|

2200-2250

|

2200

|

2200

|

2200

|

2200

|

2150

|

2250

|

2250

|

|||||||

|

Apparent Porosity (%)

|

18-20

|

≤15

|

≤16

|

≤24

|

≤24

|

≤25

|

≤18

|

≤18

|

|||||||

|

Cold Crushing Strength (MPa)

|

30-35

|

≥58.8

|

≥49.0

|

≥29.4

|

≥24.5

|

≥19.6

|

≥49.0

|

≥34.3

|

|||||||

|

Reheat test

permanent linearchange after heating

at

|

(1350℃%,3h)

|

-

|

-

|

-

|

0~-3

|

0~-0.5

|

-

|

-

|

|||||||

|

|

(1400℃%,2h)

|

-

|

-

|

-

|

-

|

-

|

0~-0.4

|

0~-0.4

|

|||||||

|

|

(1450℃%,3h)

|

0~-2

|

0~-3

|

0~-0.4

|

-

|

-

|

-

|

-

|

|||||||

|

0.2 MPa soft under load (%)

|

|

≥1450

|

≥1430

|

≥1400

|

≥1350

|

≥1300

|

≥1450

|

≥1400

|

|||||||

|

Al2O3 (%)

|

|

≥42

|

≥42

|

≥42

|

≥40

|

≥36

|

≥40

|

≥40

|

|||||||

|

Fe2O3 (%)

|

|

≤1.7

|

≤1.7

|

-

|

-

|

-

|

≤1.5

|

≤1.5

|

|||||||

Hot Searches