- Product Details

- {{item.text}}

Quick Details

-

Shape:

-

D

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

lana f

-

Model Number:

-

dee type, D shape

-

Product name:

-

stainless d type shackle

-

Size:

-

1/4" ~ 4-1/2"

-

Certification:

-

ISO9001:2008, ISO14001:2004

-

Surface:

-

Polished

-

Usage:

-

Key Holder,Bag Hook,Belt Hook etc

-

Packing:

-

iron pallet,gunny bag,woven bag,box and others

-

Keyword:

-

Stainless Steel Bolt Snap Hook

-

Technology:

-

Hot-forged

Quick Details

-

Measurement system:

-

Metric, Imperial (Inch)

-

Application:

-

Mining, Water Treatment, Healthcare, Retail Industry, Oil & Gas, Automotive Industry

-

Material:

-

Stainless steel

-

Shape:

-

D

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

lana f

-

Model Number:

-

dee type, D shape

-

Product name:

-

stainless d type shackle

-

Size:

-

1/4" ~ 4-1/2"

-

Certification:

-

ISO9001:2008, ISO14001:2004

-

Surface:

-

Polished

-

Usage:

-

Key Holder,Bag Hook,Belt Hook etc

-

Packing:

-

iron pallet,gunny bag,woven bag,box and others

-

Keyword:

-

Stainless Steel Bolt Snap Hook

-

Technology:

-

Hot-forged

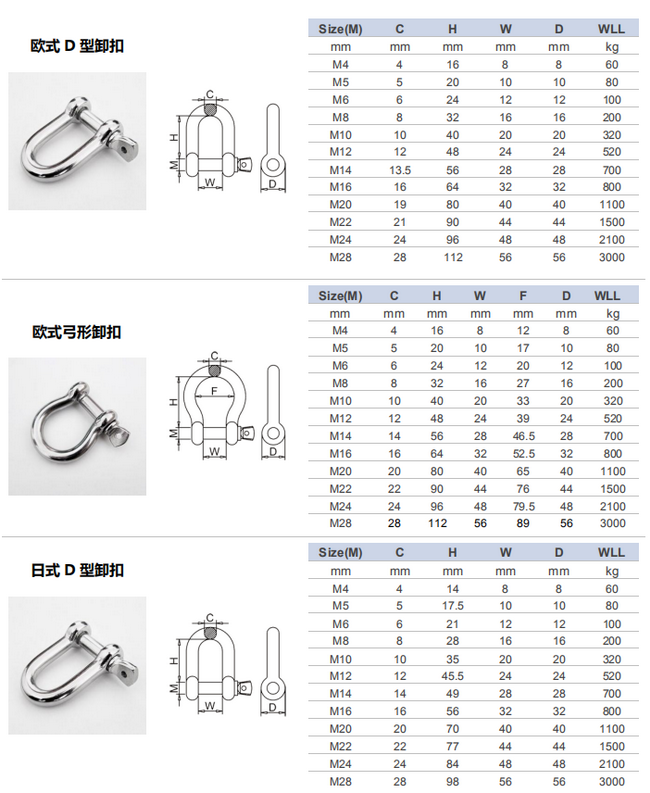

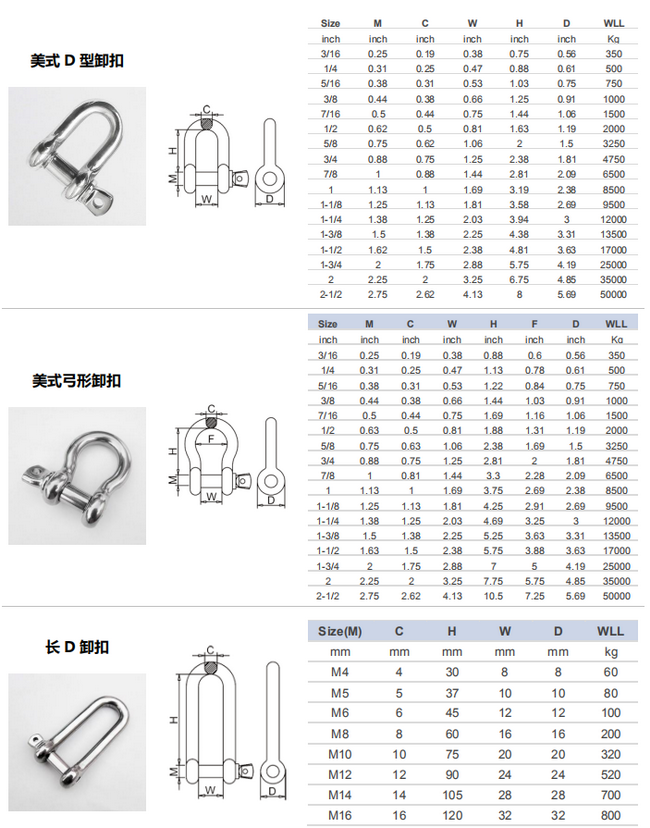

stainless D Shackle With Screw Pin Eurnpean TYPE

This product is made of high quality 304 stainless steel with a glossy surface.

It can prevent corrosion and rust in humid environment. Unbuckle is widely used in electric power, metallurgy, petroleum, machinery, railway, chemical industry, port, mine, construction and other industries.

general requirements

1. The unloading should be smooth and smooth, and cracks, sharp edges, overburning and other defects are not allowed.

2. It is strictly forbidden to use cast iron or cast steel unloading. The fastener can be forged with killed steel and the pin can be machined after bar forging.

3. No drilling or welding repair should be done on the unloading. The fastener and pin shall not be repaired after permanent deformation.

4. When using, fasteners and bolts should be inspected, and no serious wear, deformation and fatigue cracks should be allowed.

5. When in use, the transverse spacing shall not be subject to tension, and the pin must be inserted with a safety pin.

6. After the correct assembly of the pin, the width of the fastener body shall not be significantly reduced, and the thread connection is good.

7. The use of unloading shall not exceed the prescribed safety load.

test

1. It should be smooth and smooth. There should be no cracks, sharp edges and over-burning. Magnifiers can be used to review suspicious areas.

2. Unloading is carried out with double safety load as test load. The pin shall not be permanently deformed and can rotate freely after loosening. The increment of the length and size of the fastener shall not exceed O.25% or O.5 mm.

3. Sampling reliability test can be carried out for unloading. The load is twice the test load. The unloading shall not break or cause the unloading to lose the bearing capacity of the deformation.

4. The safety loads of current unloading shall be approved at M(4) level.

5. Strength grade and safety load

should be marked on the fastener.

Scrap standard 1. There is obvious permanent deformation or the pin can not rotate freely.

2. The wear of the fastener and pin at any section is more than 10% of the original size. 3. Cracks appear at any place of unloading. 4. Unlocking cannot be blocked. 5. Unqualified after unloading test.

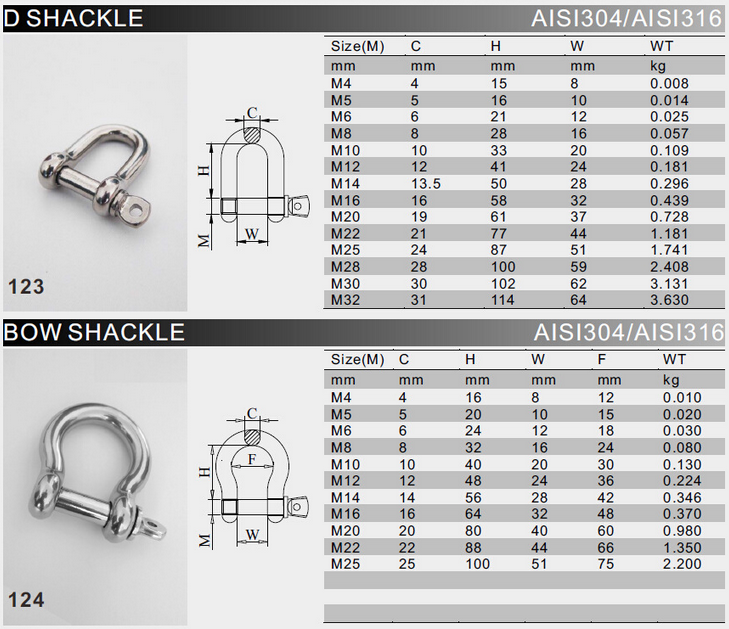

photoes of D shackle