- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

217-496-1

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

DEEPSEA

-

Model Number:

-

DS-SS

-

Type:

-

Two component type

-

Product name:

-

Silicone Sealant

-

Shape:

-

Smooth paste without bubble or particles

-

Application:

-

Glasses, building sealing

-

Specific Gravity:

-

1.5 to 1.6g/ml

-

Full Cure Time:

-

24-72hours

-

Skin Time:

-

10-60Mins

-

Working temperature:

-

-5 to 80℃

-

Shelf life:

-

2 Years

-

Packing:

-

200 kg / Iron drum, 1000 kgs/ IBC

-

Keywords:

-

silicone sealant

Quick Details

-

CAS No.:

-

9006-00-6

-

Other Names:

-

silicone adhesive

-

MF:

-

C2H6OSi

-

EINECS No.:

-

217-496-1

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

DEEPSEA

-

Model Number:

-

DS-SS

-

Type:

-

Two component type

-

Product name:

-

Silicone Sealant

-

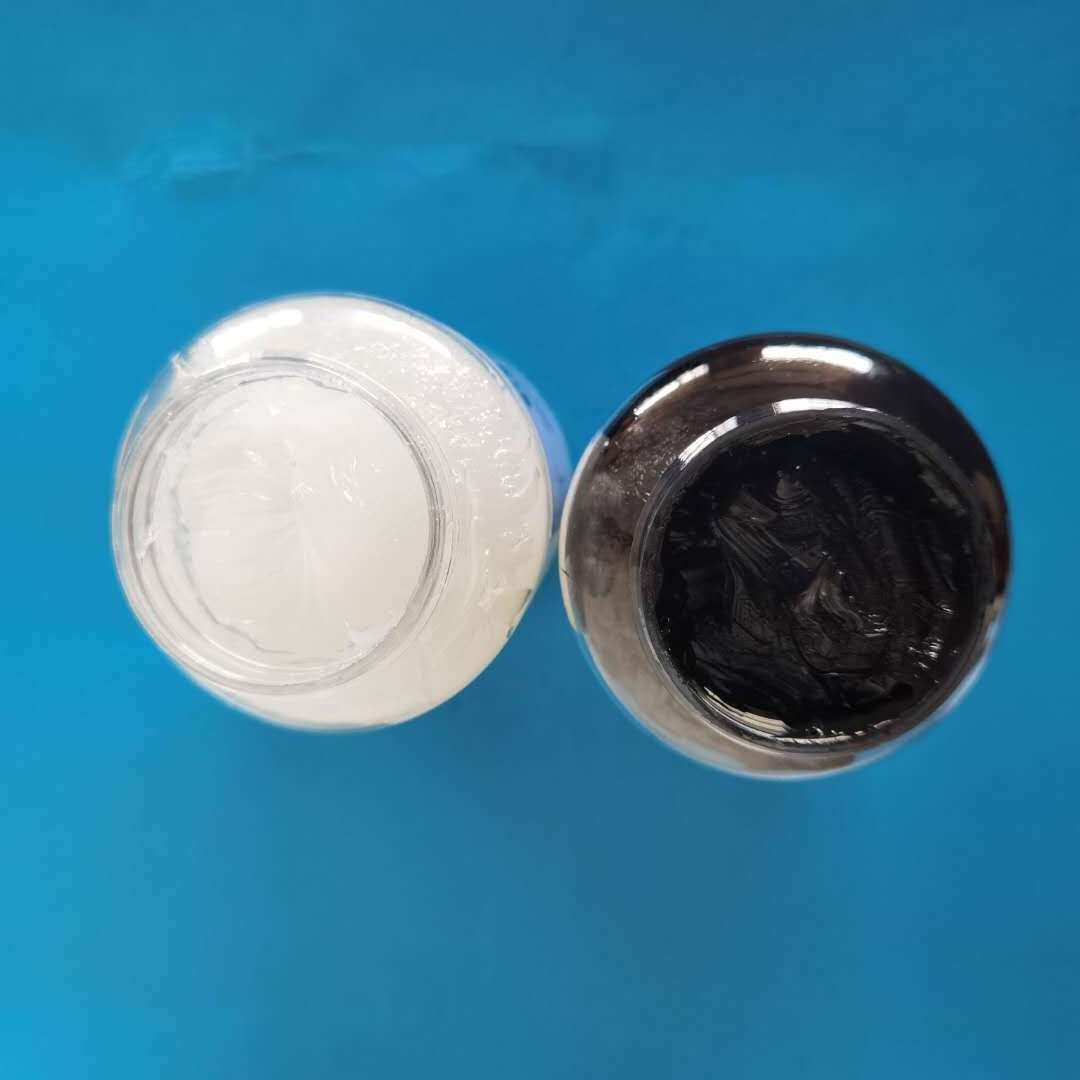

Shape:

-

Smooth paste without bubble or particles

-

Application:

-

Glasses, building sealing

-

Specific Gravity:

-

1.5 to 1.6g/ml

-

Full Cure Time:

-

24-72hours

-

Skin Time:

-

10-60Mins

-

Working temperature:

-

-5 to 80℃

-

Shelf life:

-

2 Years

-

Packing:

-

200 kg / Iron drum, 1000 kgs/ IBC

-

Keywords:

-

silicone sealant

Product Description

Physical And Chemical Features :

1. Smoothness & softness & hydrophobicity & good chemical stability & insulation property

2. High and low temperature resistance & high flash point.

3. Low freezing point (it can be chronically used in the temperature from -50℃ to +200 ℃).

4. Small viscosity-temperature coefficicent & big compression ratio & low surface tension.B

Advantages of Silicone Oil:

1. Silicone oil is a colorless, odorless, non-toxic and non-irritating products, chemical stability, heat resistance, cold

resistance, water repelled, lubricity, high refraction, storage stability and compatibility with commonly used in many filed.

2. Pure silicone fluids are clear, colorless, and odorless linear Polydimethylsiloxane fluids / PDMS. They are characterized by

their low pour points, high flash points, wide service temperature range, low viscosity change at temperature (low VTC),

excellent lubricity, high dielectric strength, and inertness to virtually all substrates.

3. Silicone fluids are 100% PDMS silicone oils that are characterized by their wide service temperature range, high flash points,

high dielectric strength and excellent lubricity.

4. Silicone Fluids are widely used in Flow Control, Temperature Control and Motion Control technologies. They are especially

advantageous for instruments, gauges and devices that are subject to extreme temperatures and high pressures.

1. Smoothness & softness & hydrophobicity & good chemical stability & insulation property

2. High and low temperature resistance & high flash point.

3. Low freezing point (it can be chronically used in the temperature from -50℃ to +200 ℃).

4. Small viscosity-temperature coefficicent & big compression ratio & low surface tension.B

Advantages of Silicone Oil:

1. Silicone oil is a colorless, odorless, non-toxic and non-irritating products, chemical stability, heat resistance, cold

resistance, water repelled, lubricity, high refraction, storage stability and compatibility with commonly used in many filed.

2. Pure silicone fluids are clear, colorless, and odorless linear Polydimethylsiloxane fluids / PDMS. They are characterized by

their low pour points, high flash points, wide service temperature range, low viscosity change at temperature (low VTC),

excellent lubricity, high dielectric strength, and inertness to virtually all substrates.

3. Silicone fluids are 100% PDMS silicone oils that are characterized by their wide service temperature range, high flash points,

high dielectric strength and excellent lubricity.

4. Silicone Fluids are widely used in Flow Control, Temperature Control and Motion Control technologies. They are especially

advantageous for instruments, gauges and devices that are subject to extreme temperatures and high pressures.

Specification

|

Applications

|

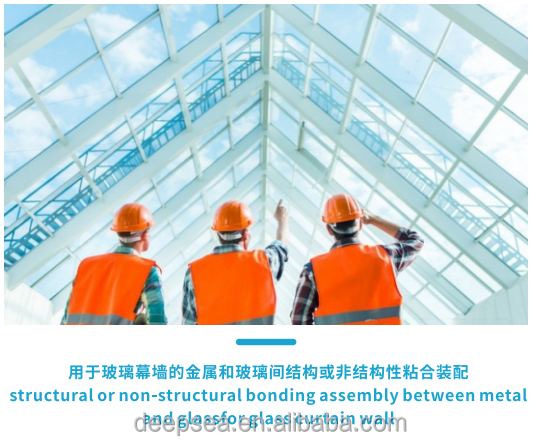

DEEPSEA silicone sealant is an engineering specific sealant that has excellent adhesion without the need for primer. It can

form strong adhesion with most building materials and has excellent aging stability, waterproof, high-temperature, and frost resistance |

|

Main Material

|

Water-based acrylic polymer

|

|

Type

|

Single componant acrylate sealant

|

|

Certification

|

REACH/ISO

|

|

Colors

|

Black/White/Blue

|

|

Appearance

|

Smooth paste without bubble or particles

|

|

Specific Gravity

|

1.5-1.6g/ml

|

|

Skin Time

|

10-60Mins

|

|

Full Cure Time

|

24-72hours

|

|

Tensile Strength

|

≥0.60Mpa

|

|

Elonation at break

|

100-300%

|

|

Hardness Shore A

|

>40

|

|

Working temperature

|

-5 to 80℃

|

|

Extrusion Rate

|

300g/min

|

|

Joint movement capability

|

7.5-12.5P%

|

|

Shelf Life

|

12-18 months (store 0-40℃)

|

|

Sample

|

FREE

|

|

Keywords

|

silicone sealant

|

silicone sealant Application .

1. Acid silicone sealant can replace various rubber pads, asbestos pads, corks and paper pads, and is used for the sealing of flat flanges and cover plates of electromechanical equipment such as automobiles, motorcycles, pipes and various water pumps.

Electronic parts fixing, circuit board bonding, glass, lighting, building materials industry.

2. Neutral silicone sealant with good bonding strength and sealing performance for most materials. The silicone rubber has excellent electrical insulation properties, moisture-proof, anti-corona, and shock-absorbing buffering; it has good high and low temperature resistance, with a temperature range of -60 to 300 °C; excellent outdoor aging resistance, with a service life of up to 20 ~30 years; no yellowing, no oil leakage, excellent comprehensive performance. Seals adhesive cracks and gaps, is widely used, waterproof, mildew-resistant, and has long-lasting stretch.

Electronic parts fixing, circuit board bonding, glass, lighting, building materials industry.

2. Neutral silicone sealant with good bonding strength and sealing performance for most materials. The silicone rubber has excellent electrical insulation properties, moisture-proof, anti-corona, and shock-absorbing buffering; it has good high and low temperature resistance, with a temperature range of -60 to 300 °C; excellent outdoor aging resistance, with a service life of up to 20 ~30 years; no yellowing, no oil leakage, excellent comprehensive performance. Seals adhesive cracks and gaps, is widely used, waterproof, mildew-resistant, and has long-lasting stretch.

Construction process: .

1. Remove grease, moisture, dust and other dirt on the sealing surface and make it dry.

2. According to the shape of the internal components of the machine, the glue is applied continuously and uniformly, and the thickness of the glue is 1.5~3.5ram.

2. According to the shape of the internal components of the machine, the glue is applied continuously and uniformly, and the thickness of the glue is 1.5~3.5ram.

3. After 10-20 minutes of drying at room temperature, the parts can be folded and assembled.

Packing & Delivery

Packing Details

1. 25Kgs / plastic drum ; 50Kgs / plastic drum ; 200Kgs / iron drum ; 200Kgs / plastic drum ; 1000Kgs / IBC Package / ; 20.5MT / ISO TANK

2.We can also customize special package according to your requirement.

1. 25Kgs / plastic drum ; 50Kgs / plastic drum ; 200Kgs / iron drum ; 200Kgs / plastic drum ; 1000Kgs / IBC Package / ; 20.5MT / ISO TANK

2.We can also customize special package according to your requirement.

Shipping Methods:

1. Samples and Small quantity order FedEx/DHL/UPS/TNT ,Door to Door.

2.Batch goods :By Air, by Sea or by Rail

3, FCL: Airport/Seaport/Railway Station receiving

1.Lead Time: 1-7 working days for samples; 7-15 working days for mass

1. Samples and Small quantity order FedEx/DHL/UPS/TNT ,Door to Door.

2.Batch goods :By Air, by Sea or by Rail

3, FCL: Airport/Seaport/Railway Station receiving

1.Lead Time: 1-7 working days for samples; 7-15 working days for mass

Hot Searches