- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

2000 mm

-

Width of Working Table (mm):

-

2000 mm

-

Dimension:

-

5780*3100*2300

-

Place of Origin:

-

Anhui, China

-

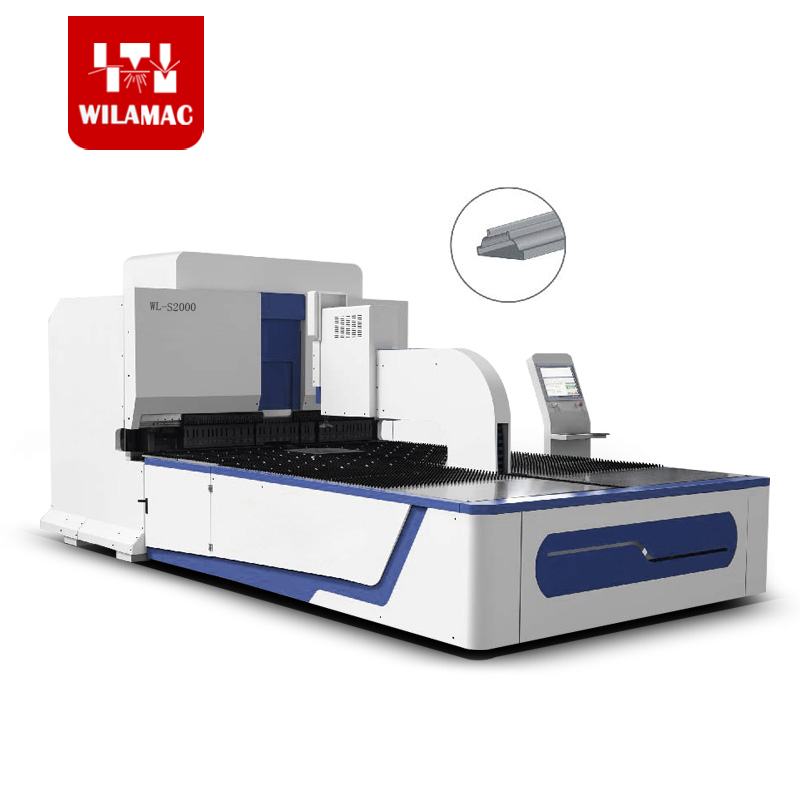

Brand Name:

-

WILMAC

-

Year:

-

2023

-

Weight (KG):

-

20000

-

Motor Power (kw):

-

55 kw

-

Marketing Type:

-

New Product 2023

-

Warranty of core components:

-

1 years

-

Feeding mode:

-

Sucked type/Pressure Arm Type

-

Bending Length:

-

1400-2500mm

-

Max bending height:

-

170mm

-

Min bending height:

-

4mm

-

Bending angle:

-

0-180°

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

2000

-

Slider Stroke (mm):

-

170 mm

-

Throat Depth (mm):

-

2000 mm

-

Width of Working Table (mm):

-

2000 mm

-

Dimension:

-

5780*3100*2300

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

WILMAC

-

Year:

-

2023

-

Weight (KG):

-

20000

-

Motor Power (kw):

-

55 kw

-

Marketing Type:

-

New Product 2023

-

Warranty of core components:

-

1 years

-

Feeding mode:

-

Sucked type/Pressure Arm Type

-

Bending Length:

-

1400-2500mm

-

Max bending height:

-

170mm

-

Min bending height:

-

4mm

-

Bending angle:

-

0-180°

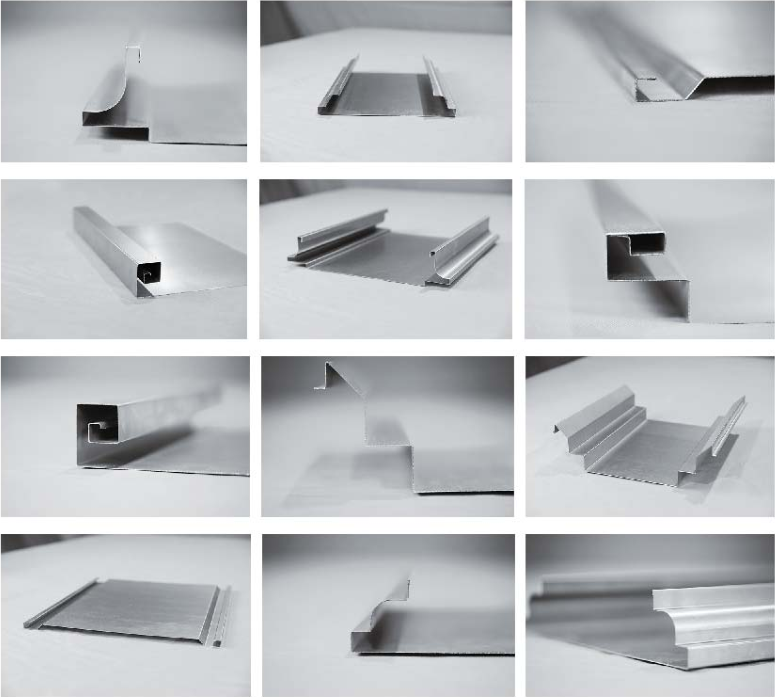

Product Description

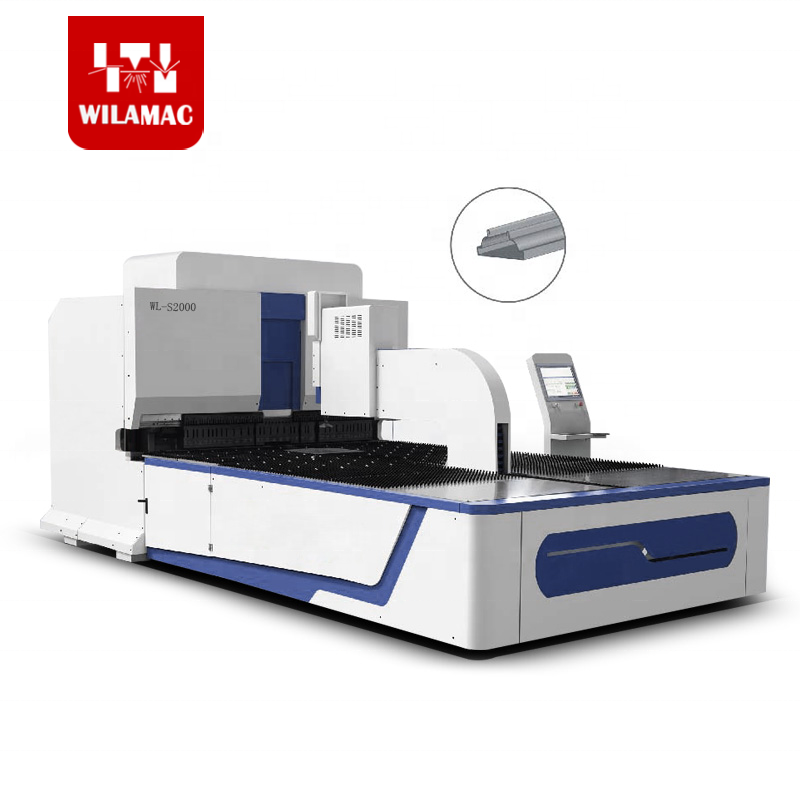

The intelligent flexible bending center

is an automation product developed for the sheet metal industry to improve production efficiency, reduce labor intensity and enhance corporate image. The equipment has 4.0 industrial architecture intelligent flexibility, fast working speed, rapid workpiece forming, high consistency, low power consumption, simple daily maintenance, high degree of automation, and simple operation, it is suitable for processing stainless steel cold plate and aluminum Plate and other industries, can bend right angle, arc, up fold, down fold, dead edge and other complex shape combinations, and can be compatible with manual loading and unloading or robot loading and unloading or manipulator loading and unloading

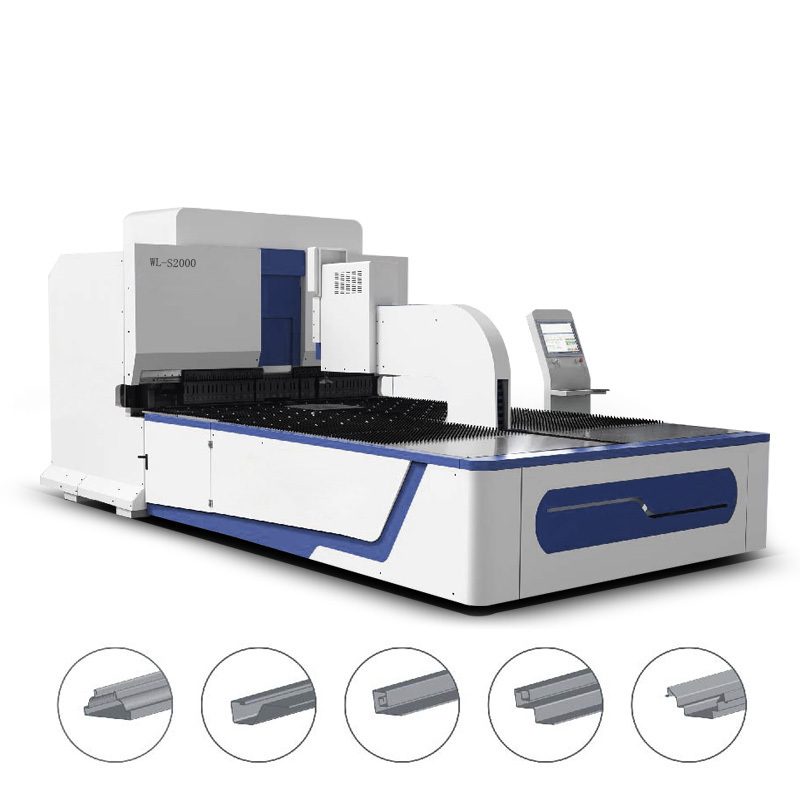

Pressure Arm Type

sucked type

Using a pure electric servo full closed-loop system, the bending action is smooth, the mechanical operation coordination is high the combination of various complex actions can be realized smoothly, and the working efficiency of the whole machine is very high. The suction cup feeding mode can realize 360 * random rotation, and the loading and unloading operation is simple, which greatly improves the safety of operators, easy to operate and safe.

|

Technical parameter

|

Flexible bending center model

|

|

|

||

|

model

|

WL-1400

|

WL-2000

|

WL-2500

|

||

|

Feeding mode

|

sucked type

|

Pressure Arm Type

|

Pressure Arm Type

|

||

|

Bending Length

|

1400mm

|

2000mm

|

2500mm

|

||

|

Max bending height

|

170mm

|

170mm

|

170mm

|

||

|

Min bending height

|

4mm

|

4mm

|

4mm

|

||

|

Min forming size of one side

|

160mm

|

180mm

|

180mm

|

||

|

Bending angle

|

0-180°

|

0-180°

|

0-180°

|

||

|

Number of control axes

|

9

|

10

|

10

|

||

Packing & Delivery

Hot Searches