- Product Details

- {{item.text}}

Quick Details

-

Machine Name:

-

PCB Brushing Machine for single board or double board

-

Model:

-

MB-700

-

working width:

-

700mm

-

brushing type:

-

double brushing & single brushing

-

Power supply:

-

380V/440V/50HZ/60HZ

-

Function:

-

Metal surface brushing & polishing

-

Application:

-

SMT PCB Assembly Production Line

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

SXY

-

Model Number:

-

MB-700

-

Machine Name:

-

PCB Brushing Machine for single board or double board

-

Model:

-

MB-700

-

working width:

-

700mm

-

brushing type:

-

double brushing & single brushing

-

Power supply:

-

380V/440V/50HZ/60HZ

-

Function:

-

Metal surface brushing & polishing

-

Application:

-

SMT PCB Assembly Production Line

Product Description

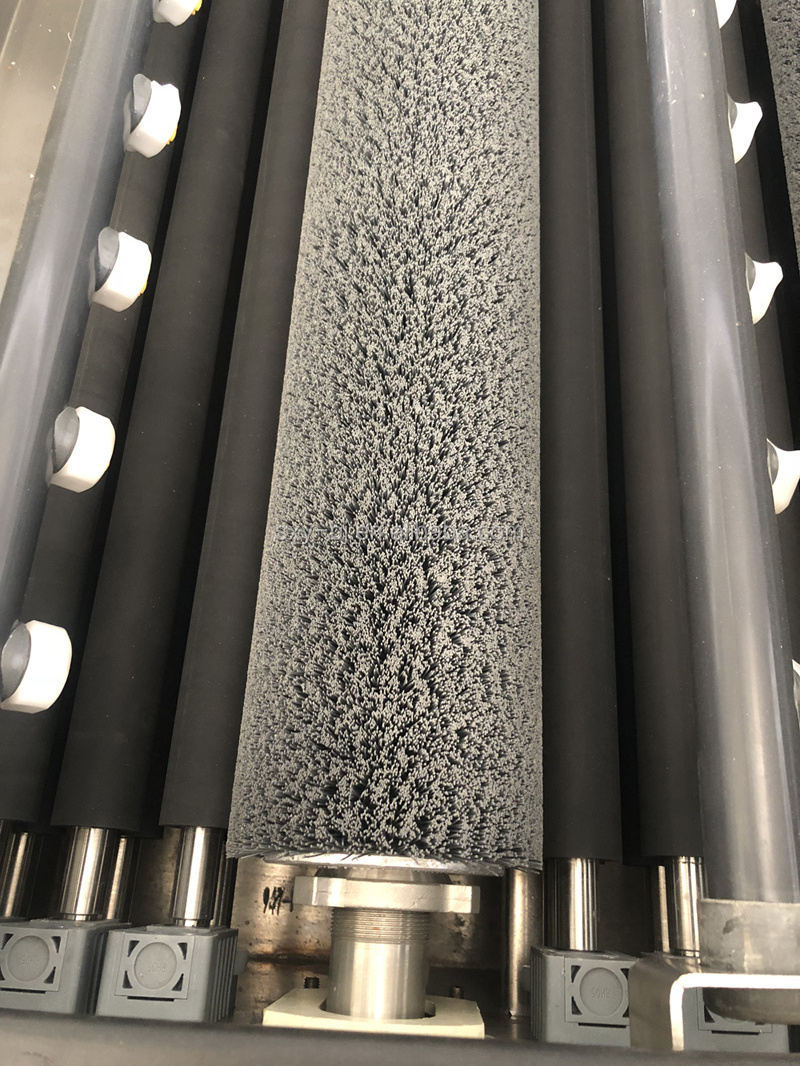

Automatic Double SIde PCB Brushing Machine

1. This brushing machine is used for PCB industry or metal surface chemical polishing work.

For PCB industry,can remove oxidation layer from copper foil,it is used before elecroplating work, pre-treatment HASL production, post-treatment HASL production.

|

Automatic Double SIde PCB Brushing Machine

|

|

|

|

|||

|

Power supply

|

|

380V/440V/50HZ/60HZ

|

|

|||

|

Working width

|

|

700mm

|

|

|||

|

Working height

|

|

925mm ( +/-50mm)

|

|

|||

|

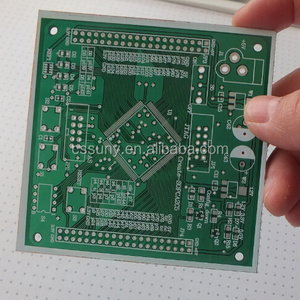

PCB Board Requirement

|

|

Thickness: 0.2~3.2mm

Min size: 80x100mm

Max size:500x600mm

|

|

|||

|

Brushing Area

|

|

single brushing or double brushing with oscillation system

|

|

|||

|

Rinse Area

|

|

Double Spraying Rinse & high pressure rinse part

|

|

|||

|

Transmission speed

|

|

0.5~6 Meter/Min (adjust)

|

|

|||

|

Machine Material

|

|

PP plate & Steel plate with Painting

|

|

|||

|

Machine Size

|

|

6800x1650x1700mm

|

|

|||

|

Introduction:

|

|

|

|

|||

|

Double Side PCB brushing machine is used for remove oxidation layer on copper board.

1. The brushing machine can clean the oxidation layer or dust on aluminum sheet,increase the surface area of the surface of the plate, conducive to dry film and plate bonding.

2.Stable and reliable transmission system, reasonable swing durable institutions,as well as very convenient brush roller replacement of the mechanical structure, which greatly improved the production efficiencyand product quality;

3.Well-designed water systems, significantly save the water consumption.

|

|

|

|

|||

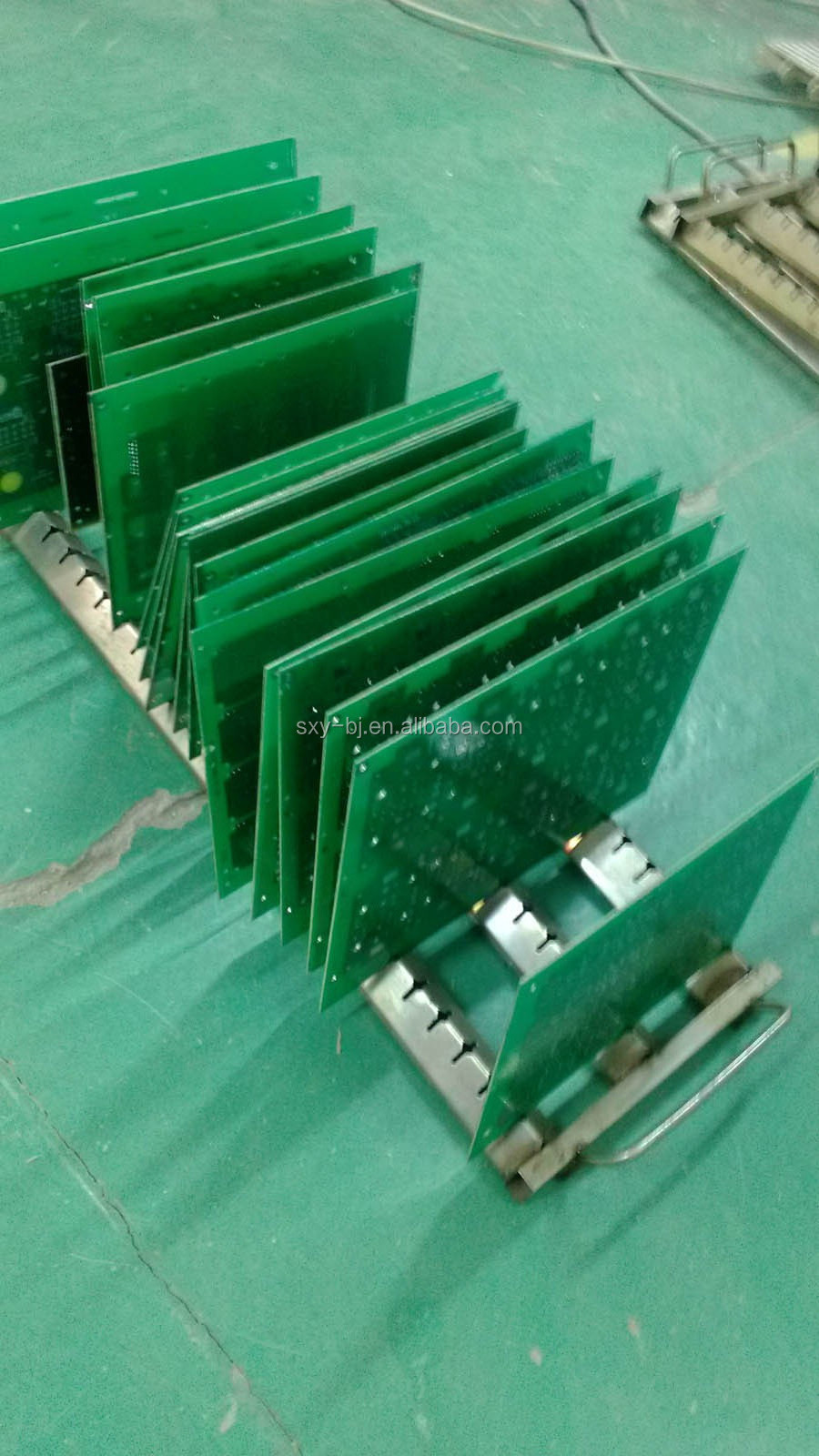

Products Show

Application

Our Service

CONTACTS

Hot Searches