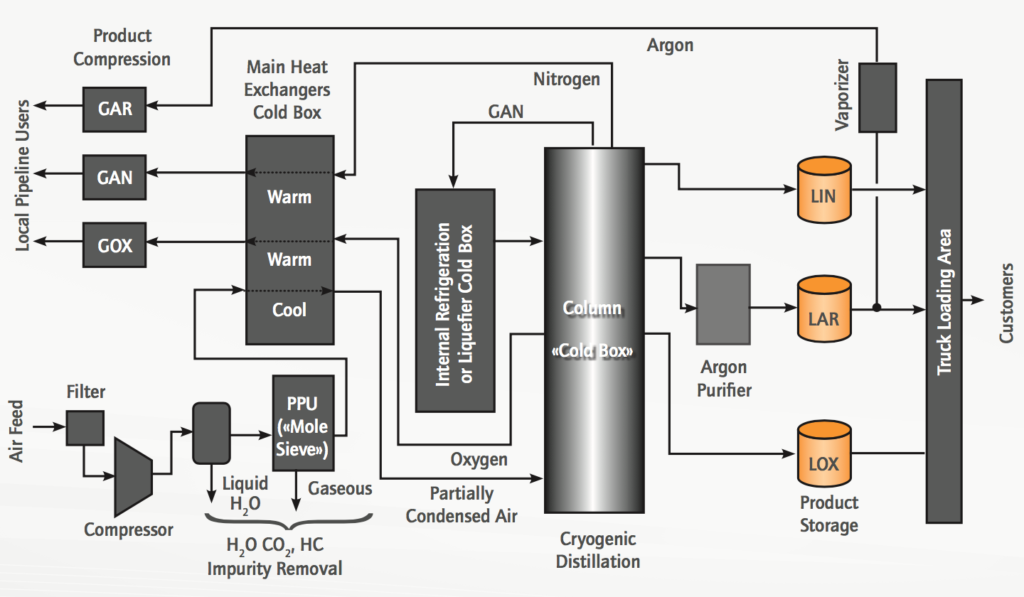

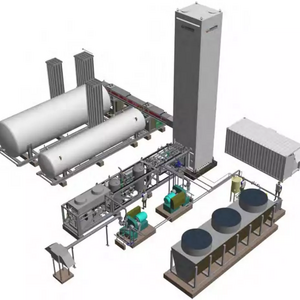

1. Air Compressor

Air is compressed at a very pressure of 5-7 bar (kg/cm2). Air can be compressed at such low pressure by trouble free rotary compressor (Screw / Centrifugal Type/Oil free piston compressor of advanced technology are employed).

2. Pre-cooling System

The second stage of the process uses a low pressure refrigerant for pre-cooling the processed air to temperature around 12 deg C before it enters the purifier.

3. Purifier

The air enters a purifier consisting of twin Molecular Sieve driers, working alternatively. The Molecular Sieves remove the Carbon dioxide & moisture from the processed air before the air enters Air Separation Unit.

4. Cooling System

The air has to be cooled to sub zero temperatures for liquification & the cryogenic refrigeration & the cooling is provided by highly efficient turbo expander, which cools the air to temperature almost below -165 to-170 deg C

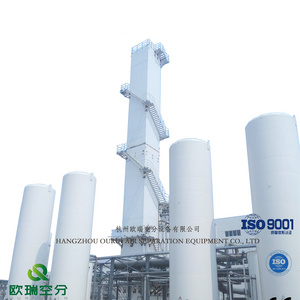

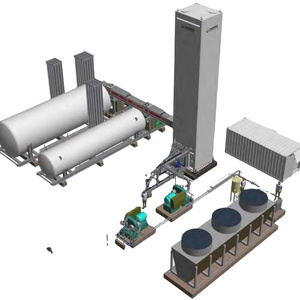

5. Separation Tower

Oil free, moisture free and Carbon Dioxide free air enters into low pressure fin type HEAT EXCHANGER where the air is cooled below sub zero temperatures by air expansion process in the turbo expander. Air gets liquefied when it enters the air separation column& gets separated into oxygen & nitrogen by the process of rectification. Oxygen is available at the outlet of the ASU at a purityof 99.6%. Nitrogen is also available t the outlet as a second product at purity of 99.9% up to 3ppm simultaneously without loss of oxygen product.

6. Oxygen/Nitrogen/Argon Gas Compressor

The final product in the form compressed Oxygen/Nitrogen goes to the high pressure oxygen cylinders at 150 bar or up to higher as required. This can be done by liquid oxygen pump is same models. We can use oil & water free compressor.

Air is compressed at a very pressure of 5-7 bar (kg/cm2). Air can be compressed at such low pressure by trouble free rotary compressor (Screw / Centrifugal Type/Oil free piston compressor of advanced technology are employed).

2. Pre-cooling System

The second stage of the process uses a low pressure refrigerant for pre-cooling the processed air to temperature around 12 deg C before it enters the purifier.

3. Purifier

The air enters a purifier consisting of twin Molecular Sieve driers, working alternatively. The Molecular Sieves remove the Carbon dioxide & moisture from the processed air before the air enters Air Separation Unit.

4. Cooling System

The air has to be cooled to sub zero temperatures for liquification & the cryogenic refrigeration & the cooling is provided by highly efficient turbo expander, which cools the air to temperature almost below -165 to-170 deg C

5. Separation Tower

Oil free, moisture free and Carbon Dioxide free air enters into low pressure fin type HEAT EXCHANGER where the air is cooled below sub zero temperatures by air expansion process in the turbo expander. Air gets liquefied when it enters the air separation column& gets separated into oxygen & nitrogen by the process of rectification. Oxygen is available at the outlet of the ASU at a purityof 99.6%. Nitrogen is also available t the outlet as a second product at purity of 99.9% up to 3ppm simultaneously without loss of oxygen product.

6. Oxygen/Nitrogen/Argon Gas Compressor

The final product in the form compressed Oxygen/Nitrogen goes to the high pressure oxygen cylinders at 150 bar or up to higher as required. This can be done by liquid oxygen pump is same models. We can use oil & water free compressor.