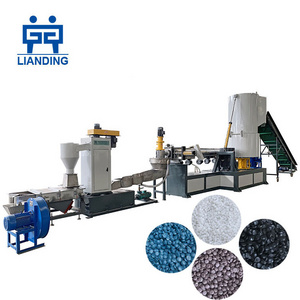

Sevenstar's high efficiency, one-step plastic recycling machine compactor is designed for the reprocessing of PE polyethylene (HDPE, LDPE, LLDPE) and PP polypropylene flexible packaging material, printed and non-printed. This cutter integrated pelletizing system eliminates the need of pre-cutting the material, requires less space and energy consumption while producing high quality plastic pellets at a productive rate.

In addition to in-house (post-industrial) film waste, the system is also able to process washed flakes, scraps and regrind (pre-crushed rigid plastic waste from injection and extrusion). This compactor plastic recycling machine is highly recommended for packaging film producers of commercial bags, garbage bags, agricultural films, food packaging, shrink and stretch films, as well as producers in the woven industry of PP woven bags, jumbo bags, tapes and yarns. Other types of material such as PS sheet, PE and PS foam, PE net, EVA, PP mixed with PU are also applicable on this compactor plastic recycling machine.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ 3P or customized

-

Dimension(L*W*H):

-

9000*9000*3500mm

-

Power (kW):

-

300

-

Weight:

-

10000

-

Screw diameter (mm):

-

130

-

Screw L/D Ratio:

-

35

-

Screw Speed (rpm):

-

1 - 75 rpm

-

Application:

-

PP PE recycling

-

Function:

-

make waste plastic into granules

-

Usage:

-

pipe, film and so on

-

Screw Diameter:

-

depend on capacity

-

Final product:

-

plastic granules

-

Cutting type:

-

water ring or noodle cutting

-

Inverter:

-

ABB brand or customized

-

recycling machine for plastic waste:

-

recycling machine for plastic waste

-

pp pe hdpe plastic pelletizer:

-

pp pe hdpe plastic pelletizer pelletizing granules

-

double stages pp pe pelletizing line:

-

double stages pp pe pelletizing line

-

Marketing Type:

-

Ordinary Product

Quick Details

-

Output (kg/h):

-

100 - 1000 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SEVENSTARS

-

Voltage:

-

380V 50HZ 3P or customized

-

Dimension(L*W*H):

-

9000*9000*3500mm

-

Power (kW):

-

300

-

Weight:

-

10000

-

Screw diameter (mm):

-

130

-

Screw L/D Ratio:

-

35

-

Screw Speed (rpm):

-

1 - 75 rpm

-

Application:

-

PP PE recycling

-

Function:

-

make waste plastic into granules

-

Usage:

-

pipe, film and so on

-

Screw Diameter:

-

depend on capacity

-

Final product:

-

plastic granules

-

Cutting type:

-

water ring or noodle cutting

-

Inverter:

-

ABB brand or customized

-

recycling machine for plastic waste:

-

recycling machine for plastic waste

-

pp pe hdpe plastic pelletizer:

-

pp pe hdpe plastic pelletizer pelletizing granules

-

double stages pp pe pelletizing line:

-

double stages pp pe pelletizing line

-

Marketing Type:

-

Ordinary Product

Product Description

double stages pp pe hdpe plastic pelletizer pelletizing line recycling machine for plastic waste granules

Detailed Images

Model of

double stages pp pe hdpe plastic pelletizer pelletizing line recycling machine for plastic waste granules

|

Model

|

Screw Diameter

(mm)

|

Rotary Speed

(rpm)

|

Main motor(Kw)

|

Compacting Machine(Kw)

|

Output(kg/h)

|

|

SJ85-33

|

85

|

10-120

|

55

|

37

|

150-180

|

|

SJ100-33

|

100

|

10-120

|

90

|

55

|

250-300

|

|

SJ130-33

|

130

|

10-120

|

132

|

75

|

300-400

|

|

SJ160-33

|

160

|

10-120

|

160

|

90

|

500-600

|

|

SJ180-33

|

180

|

10-120

|

250

|

132

|

800-1000

|

Related products

Contact us

Packing & Delivery

We use sea worthy package for make sure every machine arrive customer's factory safety.

Every machine will be tightened firmly.

Company profile

Hot Searches