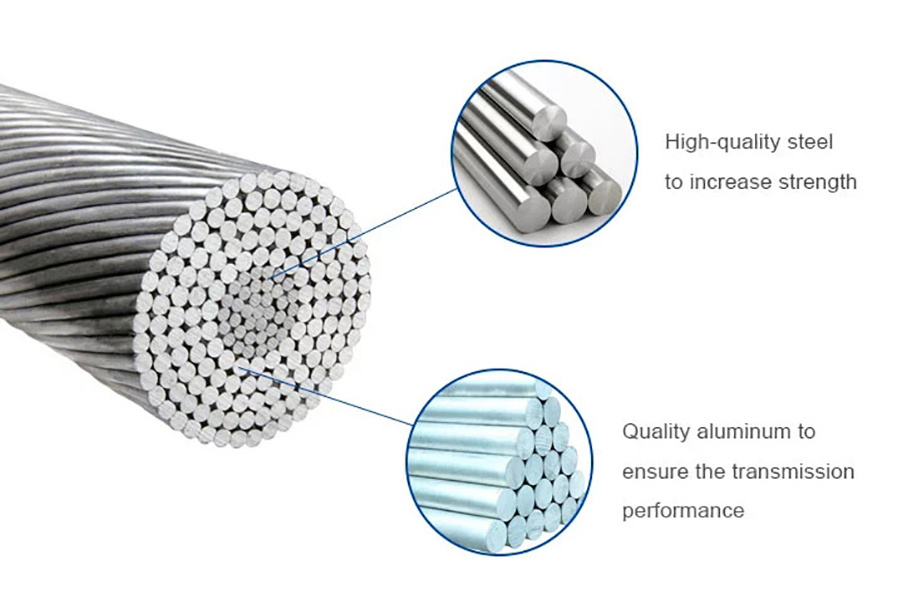

Thanks to the great number of combinations that can be made between the wires of aluminum and the wires of steel, the proportions can vary among them to obtain the best relation between the mechanical resistance and the current-carrying capacity for each type of application.

For a better protection in an atmosphere of extreme corrosion, Huaxing Cable recommends to use Class B or C galvanized steel core (zinc-coated). It produces a small reduction on the total mechanical resistance when using these types of galvanization. We can produce special orders if desired. It’s not practical to show all the types of combinations and dimensions of the cables.

Parameter:

Aluminum alloy 1350-H-19 wires, concentrically stranded about a steel core. Core wire for ACSR is available with class A, B, or C galvanizing; ""aluminized"" aluminum coated (AZ); or aluminum-clad (AW). Additional corrosion protection is available through the application of grease to the corer or infusion of the complete cable with grease.

Aluminum alloy 1350-H-19 wires, concentrically stranded about a steel core. Core wire for ACSR is available with class A, B, or C galvanizing; ""aluminized"" aluminum coated (AZ); or aluminum-clad (AW). Additional corrosion protection is available through the application of grease to the corer or infusion of the complete cable with grease.

Application :

Used as bare overhead transmission cable and as primary and secondary distribution cable.

ACSR offers optimal strength for line design. Variable steel core stranding enables desired strength to be achieved withoutsacrificing ampacity