- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2100x1200x2100

-

Weight (KG):

-

800 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Time Control:

-

YES

-

Temprature Control:

-

YES

-

Drain Tap:

-

YES

-

Data Printing Function:

-

YES

-

Filtration System:

-

Available

-

Loading Trolley:

-

Available

-

Special Fixture:

-

Available

-

Control System:

-

PLC Control with Touch Screen

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

KER

-

Power:

-

1200

-

Dimension(L*W*H):

-

2100x1200x2100

-

Weight (KG):

-

800 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Time Control:

-

YES

-

Temprature Control:

-

YES

-

Drain Tap:

-

YES

-

Data Printing Function:

-

YES

-

Filtration System:

-

Available

-

Loading Trolley:

-

Available

-

Special Fixture:

-

Available

-

Control System:

-

PLC Control with Touch Screen

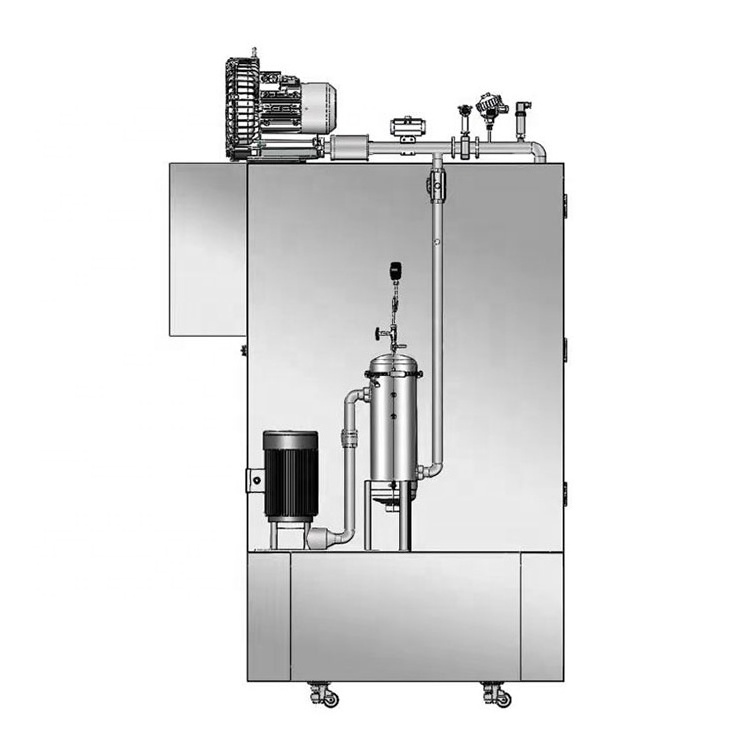

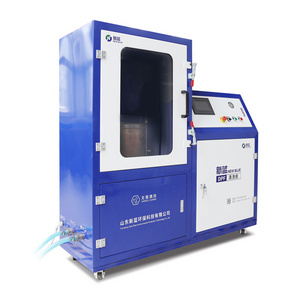

Industry dpf safety cleaner machine

Flash-JET Particulate Filter Cleaning machine custom dpf cleaner is a machine that cleans all kind of air filters of industrial vehicles (buses, trucks, construction equipment, air conditioners and dust collectors). Learning from advanced experience in the international and China market, it is the professional machine which uses the force of the water and air to solve in a definitive way all the filters cleaning problems.

| Model | Flash-JET | Flash-JET Pro |

| External Dimensions | 2000 x 850 x2700 MM | 2320× 1150× 2600 MM |

| Floor Load Capacity | 200KG | 200KG |

| Tank Capacity | 200L | 150L+ 150L = 300L |

| Power Consumption | 19.57 KW | 23.77 KW |

| Max. Current | 42A | 49A |

| Power Supply | 380V, 50Hz, 3Ph+N+PE | |

| Packaging Size | L2340 x W1130 x H2350 MM | L2440 x W1320 x H2350 MM |

| Net Weight | 880 KG | 1000KG |

| Gross Weight | 1200 KG | 1400KG |

| Configurations |

Standard:

Heating system, oil & mist cleaner, drying system, water recirculation system, liquid level sensor, illuminating system, intelligent fixture, PLC control system, printer. optional: Loading & unloading auxiliary device, washing gun, wheel, cleaning detergent. |

|

|

>>

One machine for every kind of air particulate filter and for the entire cleaning cycle (washing and drying).

|

|

>> During the cleaning cycle, the water flows throughthe hole placed under the stainless-steel grid into an underlying tank and once filtered and purified it goes back in circle. >> The worktop is made of a stainless-steel grid which can bear up to 200 Kg of weight. |

|

>> Three-stage filtration system is equipped to collect the PM10 and other impurities. >> In this way, we can assure clean water for each cleaning cycle.

|

|

>> When the cycle ends, it is possible to compare the initial and the final parameters in order to verify the quality of the cleaning. >> You can print the same data on a receipt (also sticker)and deliver it to the customer or stick it on the filter. |

|

>> Siemens PLC module with steady and strong operation capacity. >> Networking function make online program checking and update available. >> 7inch high-sensitive touch screen to get smart and human-friendly operation experience. |

|

>> Oil & mist cleaner to filter oil, mist and vapor in the washing chamber and ensure good working environment. >> The water vapor after filtering will go back to tank and be recycled. |

|

>> Key electronic parts and components come from world-famous brands,such as Siemens, Schneider, Omron. >> Safety door switch is equipped. When the door is open, Flash-JET will stop working automaticallv. |

One machine for every kind of air particulate filter and for the entire cleaning cycle (washing and drying).

lt can be used for different sized DPF, SCR, FAP an air filters of different industrial vehicles(buses, trucks, construction equipment, air conditioners and dust collectors) to completely remove PM10,cerium and oil deposits without damaging the filter.