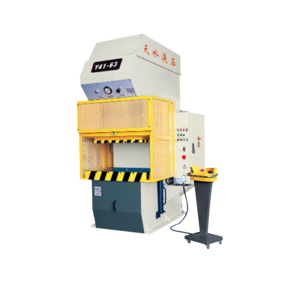

HIGH PRECISION FOR SHEET METAL PUNCHING AND STAMPING

The press body is milling and boring by PAMA machine center and all the surfaces and holes will be finished machining in on position