- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

8000

-

Name:

-

3 layer poly ethylen coating machine

-

Usage:

-

oil/gas/heating /water pipelines anti-corrosion caoting

-

Technology:

-

Three-layer polyethylene anti-corrosion coating

-

Kinds of coating:

-

FBE/AD/PE

-

Advantage:

-

Environment Friendly

-

Heating system:

-

Electric Furnace Equipment

-

Production line type:

-

Spraying Auto Parts Production Line

-

Spraying method:

-

Electric Spraying

-

Material:

-

Steel pipe

-

Training:

-

Operation Training + Routine Maintenance

Quick Details

-

Machine Type:

-

3LPE coating machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hongteng

-

Voltage:

-

Customers Local Voltage

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

Customized Size

-

Weight (KG):

-

8000

-

Name:

-

3 layer poly ethylen coating machine

-

Usage:

-

oil/gas/heating /water pipelines anti-corrosion caoting

-

Technology:

-

Three-layer polyethylene anti-corrosion coating

-

Kinds of coating:

-

FBE/AD/PE

-

Advantage:

-

Environment Friendly

-

Heating system:

-

Electric Furnace Equipment

-

Production line type:

-

Spraying Auto Parts Production Line

-

Spraying method:

-

Electric Spraying

-

Material:

-

Steel pipe

-

Training:

-

Operation Training + Routine Maintenance

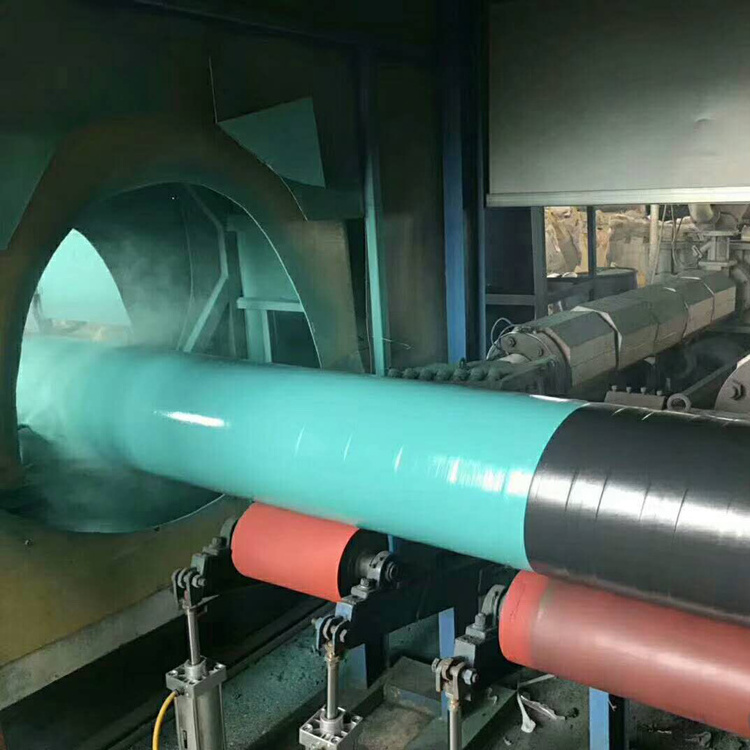

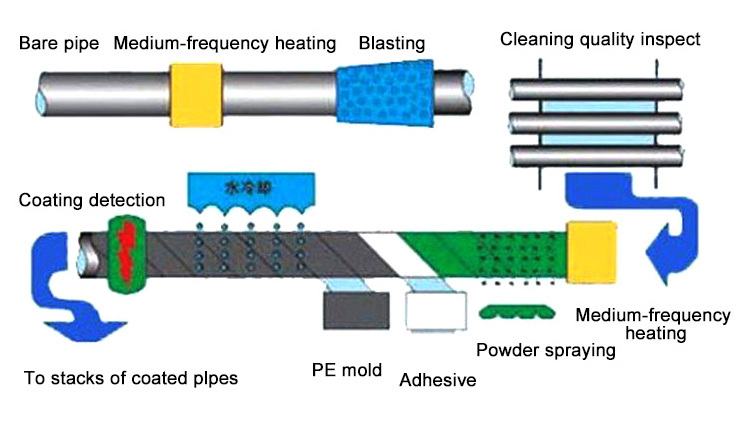

Hongteng steelpipe Epoxy Fbe Powder Coating Machine / Anti Corrosion Usage Steel Pipe Coating Machine production line

Product Description

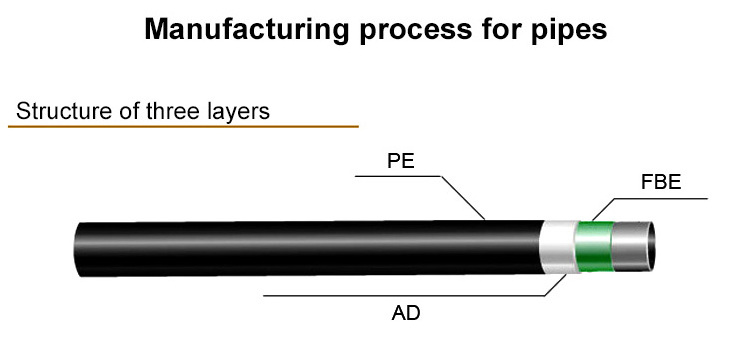

3PE anticorrosive steel pipe is generally composed of three-layer structure:

First layer: Epoxy powder (FBE>100um)

Second layer: Adhesive (AD) 170-250um

Third layer: Polythene (PE) 2.5-3.7mm

1. The coating of 3PE anti-corrosion steel pipe is the epoxy powder anticorrosive coating, and the intermediate layer is

copolymerized adhesive with functional groups of branch structure. The surface is high density polyethylene anti-corrosive

coating.

copolymerized adhesive with functional groups of branch structure. The surface is high density polyethylene anti-corrosive

coating.

2.

3PE anticorrosive coating combines the characteristics of epoxy resin and polyethylene with high impermeability and high mechanical properties. So far, it is recognized as the best pipeline anticorrosive coating with the best performance in the world. It has been used in many projects.

3.

In practice, it is firmly combined with steel pipe to form an excellent anticorrosion coating by mixing three materials into one. It is divided into winding type and circular coating type according to the processing method.

4.

3PE anticorrosive steel pipe coating, namely as Three-layer polyethylene anti-corrosion coating, is a new kind of anti-corrosion steel pipe coating produced by combining 2PE anticorrosive coating in Europe and FEB in North America. It has been recognized and used in the world for more than 10 years.

Product Advantages

1.

3PE anticorrosive steel pipe has extremely high tightness, which can greatly save energy in long-term operation. It can reduce the costs and protect environment.

2.

It has strong corrosion resistance with service life up to 30-50 years.

3.

It also has good corrosion resistance and impact resistance at low temperature.

4.

At the same time, it has high epoxy strength, low PE water absorption and good softness of hotmelts, and has high anticorrosion reliability. It is characterized by simple fabrication process, good anticorrosion effect and low price. It is a widely accepted anticorrosion method in pipeline manufacturing industry.

|

Specification and Technical Parameter

|

|

|

|

|

||||

|

Capacity(T/Hour)

|

Working hours(Year)

|

Electricity consumption

|

Feeding Section

|

Rebar diameter

|

||||

|

5

|

2400

|

5MW

|

60*60mm

|

Φ8-16mm

|

||||

|

8

|

2400

|

8.5MW

|

70*70mm

|

Φ8-16mm

|

||||

|

10

|

3600

|

9.5MW

|

90*90mm

|

Φ8-32mm

|

||||

|

15

|

3600

|

10MW

|

120*120mm

|

Φ8-32mm

|

||||

|

16

|

6000

|

15MW

|

120*120mm

|

Φ6.5-32mm

|

||||

|

35

|

6000

|

26MW

|

150*150mm

|

Φ6.5-32mm

|

||||

Use: products are wildly used in oil pipelines,natural gas pipelines,heating pipelines,water supply pipelines.

Recommend Products

Why Choose Us

Certifications

Hot Searches