- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ALWELL

-

Dimension(L*W*H):

-

240*170*230cm

-

Weight:

-

300 KG, 500 KG

-

After-sales Service Provided:

-

Online Support

-

Product name:

-

Bottle Filling Capping

-

Function:

-

Bottle Washing Filling Capping

-

Name:

-

Bottle Liquid Filling Machine

-

Usage:

-

Filling Capping Labeling Packaging

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Keywords:

-

Fillng Machine

Quick Details

-

Machinery Capacity:

-

8000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder

-

Filling Accuracy:

-

±0.1

-

Voltage:

-

220V 380V

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

ALWELL

-

Dimension(L*W*H):

-

240*170*230cm

-

Weight:

-

300 KG, 500 KG

-

After-sales Service Provided:

-

Online Support

-

Product name:

-

Bottle Filling Capping

-

Function:

-

Bottle Washing Filling Capping

-

Name:

-

Bottle Liquid Filling Machine

-

Usage:

-

Filling Capping Labeling Packaging

-

Bottle type:

-

PET Plastic Bottle Glass Bottle

-

Keywords:

-

Fillng Machine

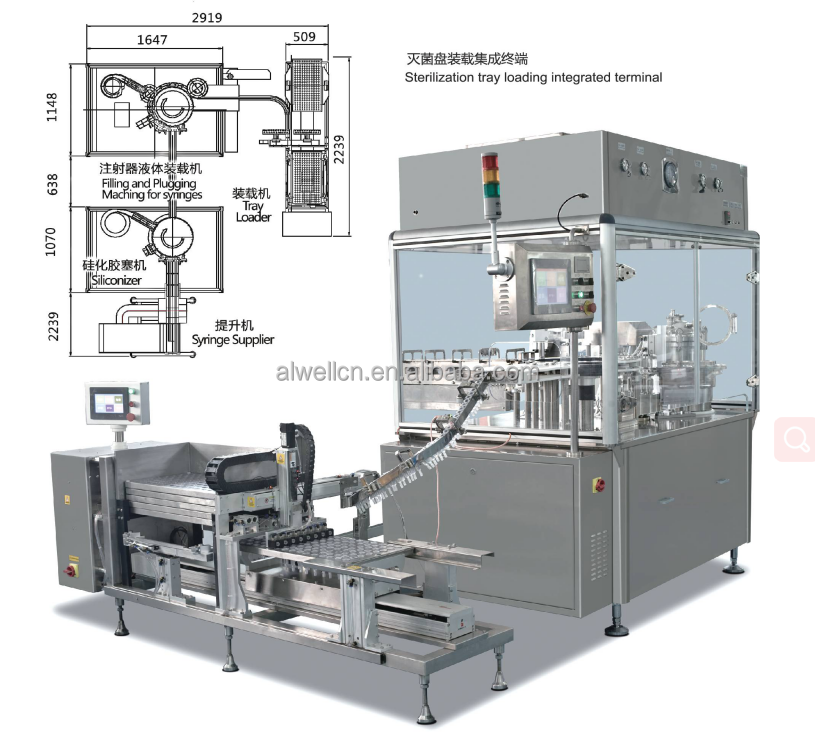

Products Description

Disposable Syringe Production Line Machinery

This machine is suitable for the glass syringe with luer lock and can fill like tooth whitening gel and hyaluronic acid. Other

type syringe filling machine we have sale too, please contact us for more information.

type syringe filling machine we have sale too, please contact us for more information.

1. This machine has compact structure, convenient installation and adjustment, overload clutch protection, fault shutdown

protection safe and reliably.

2. Adopt internationally renowned brand electrical components and servo motor combination. Fully automatic control easy to operate accurately and reliably.

3. Valveless rotary piston pump made of 316L or ceramic material with high precision ensures filling accuracy.

4. According to the requirements of the new GMP, it is designed to operate in closed mode under the A-level laminar flow

protection and the lower part of the protective door is equipped with laminar flow wind barrier. The main engine is loaded and unloaded without tools, which is convenient for specification change, cleaning and sterilization.

protection safe and reliably.

2. Adopt internationally renowned brand electrical components and servo motor combination. Fully automatic control easy to operate accurately and reliably.

3. Valveless rotary piston pump made of 316L or ceramic material with high precision ensures filling accuracy.

4. According to the requirements of the new GMP, it is designed to operate in closed mode under the A-level laminar flow

protection and the lower part of the protective door is equipped with laminar flow wind barrier. The main engine is loaded and unloaded without tools, which is convenient for specification change, cleaning and sterilization.

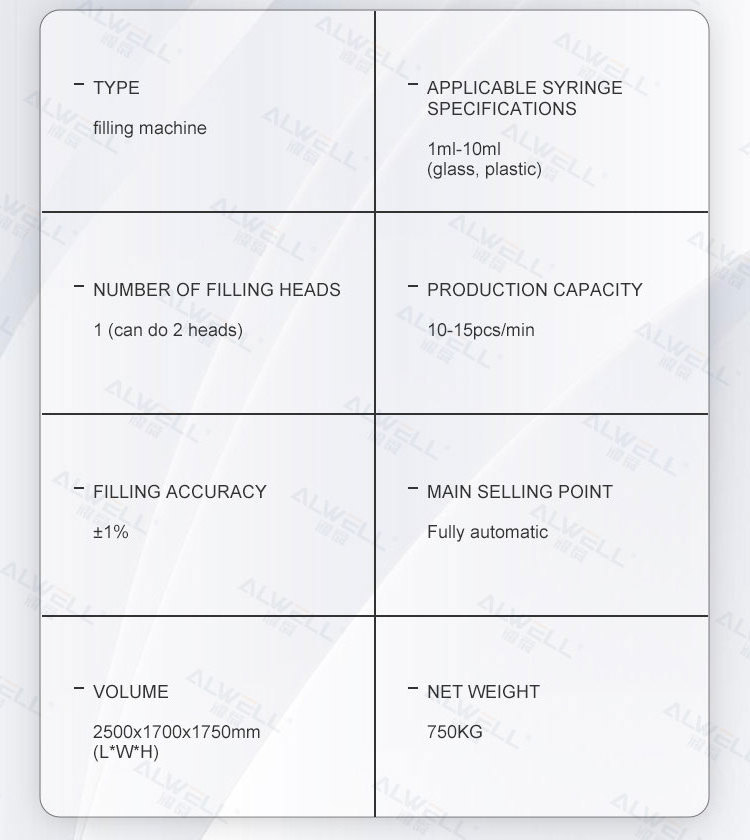

Features

|

Applicable Materials

|

Liquid and ointment

|

Liquid and ointment

|

|

Applicable Syringe Specifications

|

0.5、1、2.25、3、5、10ML

|

0.5、1、2.25、3、5、10ML

|

|

Number of Filling Heads

|

1

|

1

|

|

Number of Capping Heads

|

1

|

1

|

|

Filling Accuracy

|

≤±1-2%

|

≤±1-2%

|

|

Production Capacity

|

420-720 p/h

|

600-720 p/h

|

|

Total Power

|

2KW

|

2KW

|

|

Voltage

|

380V/220V 50-60Hz

|

380V/220V 50-60Hz

|

|

Compressed Air

|

0.55-0.75Mpa 15L/S

|

0.55-0.75Mpa 15L/S

|

|

Dimensions

|

L808×W758×H1760mm

|

L808×W758×H1760mm

|

|

Equipment Weight

|

300KG

|

300KG

|

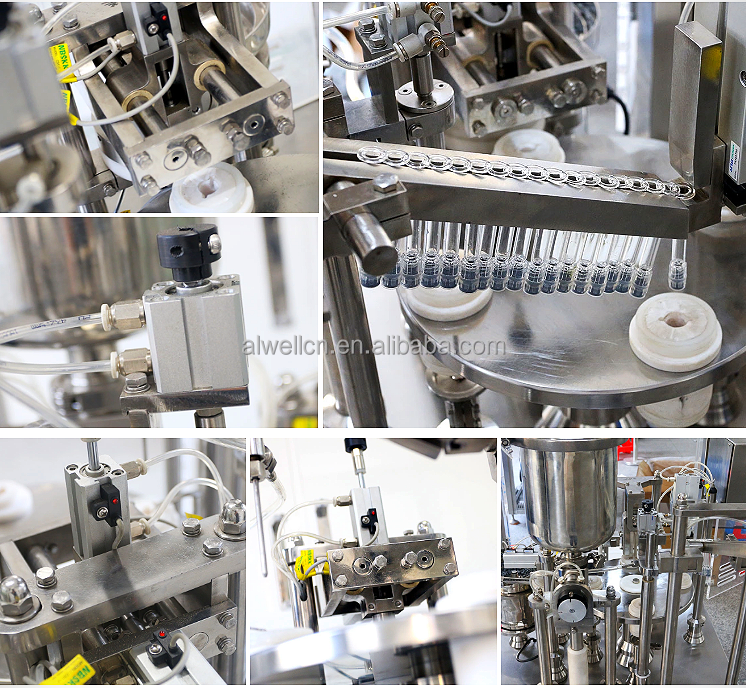

Advantages and Details

1.lntelligent control panel

The touch screen control panelmakes the working parametercan be set easily it is no need totrain operator,helps to improveworking efficiency.The language ofoperation panel can be customizedin different kinds of language,if youneed this,please contact us.

2.Stainless steel material

The surface is made of sus304stainless steel,and all the contactliquid parts are suS316L stainlesssteel and medical silicone rubber,in line with the requirements of GMP

5.Rubber stopper vibration disc

The rubber stopper is arranged in anorderly manner, and the rubber

6.Rotating disk

Rotating the astrolabe helps the tubework steadily at different stations.The rotating astrolabe should becustomized according to the size ofthe tube, filling different tubes withdifferent rotating astrolabes.

3.Vacuum filling system

Suitable for viscous materials, toensure that the liquid filling space,and no bubble or fault to improvethe qualified rate of finished products

4.Vacuum plug system

Vacuum plug filling system, avoid therubber plug vibration friction causedby particles,ensure that the rubberplug and liquid level close contact

Product Application

Hot Searches