- Product Details

- {{item.text}}

Quick Details

-

Vibrating Amplitude:

-

2-5mm

-

Length of Flexible Shaft:

-

n/m

-

Voltage:

-

110V220V230V380V400V415V440V500V600V50HZ60HZ

-

Weight:

-

100 kg

-

Dimension(L*W*H):

-

customized

-

Material:

-

Q235A

-

Load capacity:

-

variable

-

Phase:

-

3 phase

-

Size:

-

0.25 meter to 12 meters

-

Spring material:

-

High manganese steel

-

Plate thickness:

-

8mm to 25mm

-

Noise:

-

65db~75db

-

application:

-

food ,bulk materials

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

-

Certification:

-

CE ISO SGS

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DZ

-

Frequency:

-

500-3000r/m

-

Vibrating Amplitude:

-

2-5mm

-

Length of Flexible Shaft:

-

n/m

-

Voltage:

-

110V220V230V380V400V415V440V500V600V50HZ60HZ

-

Weight:

-

100 kg

-

Dimension(L*W*H):

-

customized

-

Material:

-

Q235A

-

Load capacity:

-

variable

-

Phase:

-

3 phase

-

Size:

-

0.25 meter to 12 meters

-

Spring material:

-

High manganese steel

-

Plate thickness:

-

8mm to 25mm

-

Noise:

-

65db~75db

-

application:

-

food ,bulk materials

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

-

Certification:

-

CE ISO SGS

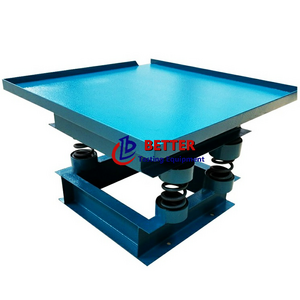

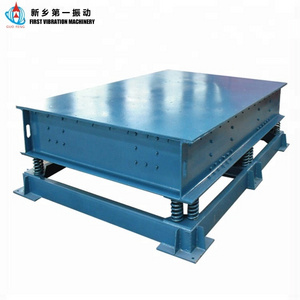

ZDP Series

Vibrating Table

The vibration tables can be found in a open or closed design and can also be designed for the demand of a sanitary environment. The operations of the vibrating tables are typically compaction/removal of air from miscellaneous materials, shake-outs at foundries, vibration of cartons and cans for reducing packaging size, vibration of bags and sacks on pallets for stabilization before wrapping and testing of electronic equipment etc. at various frequencies.

Working Principle

Vibration table is mainly composed of four parts.They are bracket, countertops, vibration,shock absorption institutions. Rubber springs and 2~8 vibrating motors are used together to vibrate materials from all directions (up and down, left and right, front and rear),leading to the effect of two or three-dimensional shake.)

After years of research and development of our company, we have developed various of vibration tables,they are divided into three types,two-dimensional vibration automatic control,three-dimensional vibration of self-control,three-dimensional FM shock (for pipeline equipment).It is suitable for precision casting,Pressure molding. And it is a stable machine with low consumption and low noise.Vibration table is used in the production process for Particles, powdery materials from the bulk to the form of a massive shape.

Vibrating Table

Spring

Horizontal Electrical Motor

|

1. Can be used in metallurg,mould,food,chemival and building materials etc.

|

|

|

|

|||

|

2. Applicable to operations where strong vibrations are required and adjustment of the vibrations during operation is not necessary

|

|

|

|

|||

|

3. Applicable to operations where high frequency and small amplitude are expedient and where an infinitely variable control of the vibrations (from 0 to 100%) during operation is requested

|

|

|

|

|||

|

Model

|

Area(m*m)

|

Power(kw)

|

Amplitude(mm)

|

Weight(kg)

|

|

ZDP-500*500

|

0.25

|

2*0.25

|

2-5

|

300

|

|

ZDP-1000*1000

|

1

|

2*0.4

|

2-5

|

600

|

|

ZDP-1200*1200

|

1.44

|

2*3.0

|

2-5

|

1200

|

|

ZDP-1500*1500

|

2.25

|

2*3.0

|

2-5

|

2000

|

|

ZDP-3000*3000

|

9

|

6*1.5

|

2-5

|

3000

|

Xinxiang Dongzhen Machinery ,located in high tech Development Zone of Xinxiang City, which is an enterprise integrated scientific researching,device producing and product marketing. We mainly produces DZ series vibrating screen,linear vibration sieve,test sieve,vibration conveyor,vibration feeder and other handling equipments.

Dongzhen Machinery mainly produces products for sieving ,conveying,elevating,and cruching. Our company has strong technical force.With the strategy aiming to abtain enterprise reputation,be bold in innovative technology and provides good service,our company has become a well-known enterprise in the industry.

Pre-sale service:

a. According the user’s different needs, we work to recommend and guide for them

b. To help them select the appropriate equipment

Service during sale:

a

. Do good communication with customers, so that each part can exchang the information.

b. Deliver on time as per the contract clause.

After-sale service:

a. To track the customer’s feedback after receiving the equipment

b. Do well about the work of maintenance and service