Made of stainless steel 304 ,surface by plating

More durable and keep long time

- Product Details

- {{item.text}}

Quick Details

-

Max Speed:

-

10-12pcs/min

-

Voltage:

-

AC220V/110V 50/60Hz

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

860*640*660mm

-

Weight:

-

72 KG

-

Product name:

-

Semi-auto ultrasonic dual chamber tube sealing machine

-

Power:

-

2.2KW

-

Frequency:

-

20KHZ

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel

-

Work air pressure:

-

0.5MPa

-

Air Consumption:

-

0.2m³/min

-

Suitable for:

-

Cosmetic products

-

Function:

-

Filling+Tail Sealing

Quick Details

-

Packaging Type:

-

Cartons, CANS, Bottles, Barrel, Stand-up Pouch, Bags, Pouch, case, Tubes

-

Packaging Material:

-

Plastic, Paper

-

Driven Type:

-

Electric

-

Max Speed:

-

10-12pcs/min

-

Voltage:

-

AC220V/110V 50/60Hz

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

860*640*660mm

-

Weight:

-

72 KG

-

Product name:

-

Semi-auto ultrasonic dual chamber tube sealing machine

-

Power:

-

2.2KW

-

Frequency:

-

20KHZ

-

Control:

-

PLC+ Touch Screen

-

Material:

-

Stainless Steel

-

Work air pressure:

-

0.5MPa

-

Air Consumption:

-

0.2m³/min

-

Suitable for:

-

Cosmetic products

-

Function:

-

Filling+Tail Sealing

Products Description

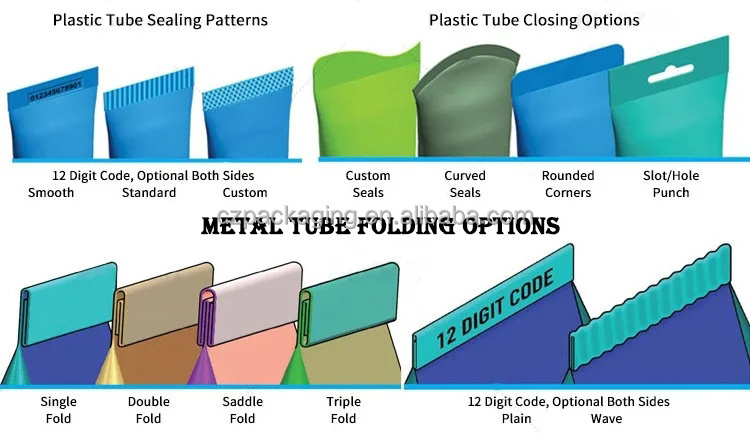

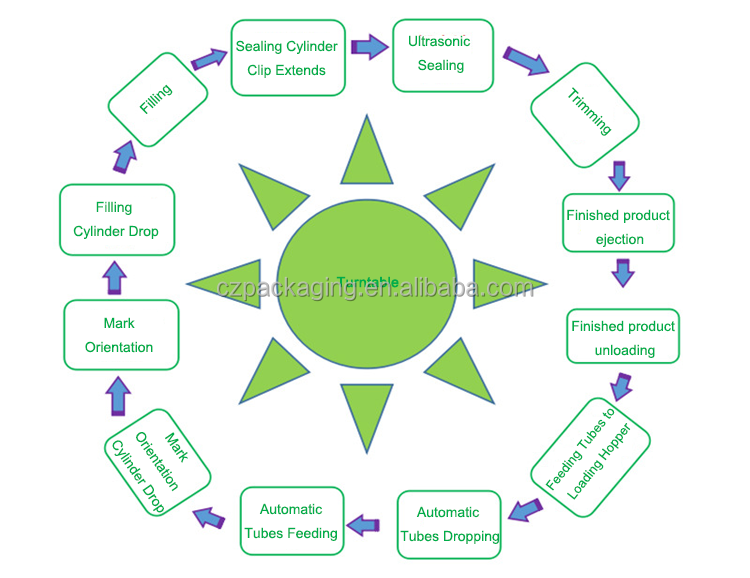

MACHINE WORKING PRINCIPLE

|

Product Name

|

Semi-auto ultrasonic tube sealing machine

|

|

Model

|

UPK-007D

|

|

Power

|

2.2kw

|

|

Voltages

|

AC220V110V 50/60Hz

|

|

Workstation

|

single station

|

|

Applicable hose types

|

Letter tube,double-layer tube

|

|

Capacity

|

10-12 pcs/min

|

|

Sealing Dia

|

12-50mm

|

|

Tube Height

|

50-220mm

|

|

Control Style

|

PLC control

|

|

Work Air Pressure

|

0.5MPa

|

|

Air Consumption

|

0.2m³/min

|

|

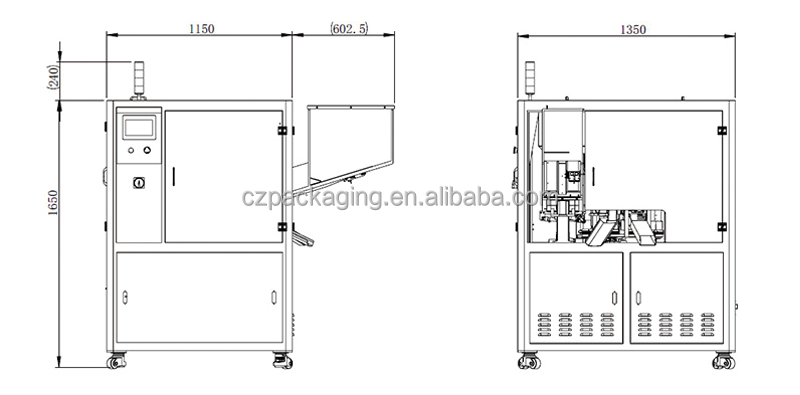

Machine Dimension

|

860*640*660mm

|

|

Machine Net Weight

|

72kg

|

Product Characteristics

Ultrasonic sealing horn

Ultrasonic sealing horn with date code letter. 5-18 digits printing custom made according to your requesting

Assist to adjusting height of each working station according to tube size

Qty: 10 working stations

Tube Holder Made by POM,more durable for using and changing

Tube Holder Made by POM,more durable for using and changing

It is used to create date codes on seals and supports date coding on the front or back.

Anti-dripping filling nozzle

All type anti-drip adapters include brass core and stainless steel spring, and NBR O-ring and ball

The touch screen is easy to operate, equipped with a power switch, emergency stop button, and alarm for safe use

Main Features

1. Easy to operate and maintain.

2. Automatic positioning, filling, welding, cutting and trimming, printing code in one time.

3. Stainless steel machine body, strong and beautiful looks.

4. Sealing mould can be customized according to customer requirements. Can seal many size of tubes.

5. Ultrasonic Sealing Machine power source for the pneumatic, working steady, not easy to damage, customers can rest assured use.

6. Ultrasonic frequency can meet international standard, no harmful to human being or environment.

7. Can be work in time, not need wait the heat time .

2. Automatic positioning, filling, welding, cutting and trimming, printing code in one time.

3. Stainless steel machine body, strong and beautiful looks.

4. Sealing mould can be customized according to customer requirements. Can seal many size of tubes.

5. Ultrasonic Sealing Machine power source for the pneumatic, working steady, not easy to damage, customers can rest assured use.

6. Ultrasonic frequency can meet international standard, no harmful to human being or environment.

7. Can be work in time, not need wait the heat time .

Advantages

1.

Using advanced ultrasonic technology for sealing, there is no need for heating or a chiller when starting up. It can be used immediately after starting up, which is energy-saving and environmentally friendly.

2.

No need for manual frequency modulation, can automatically match ultrasonic frequency.

3.

Overload protection, phase separation protection, power-fail protection.

4.

Intelligent recognition system, no tube, no filling, no sealing.

5.

Adopting a PLC touch screen control system

Product Application

Catalog

Production Process

About Us

Upack Imp. And Exp.,Ltd

is a Professional One-Stop Packing Solution Provider of Fill-Label-Cap-Shrink-Carton-Seal-Strap-Wrap-Convey-Stack process, Which has been focusing on the planning, R&D and manufacturing of automatic packaging production line. such as automatic carton packing line,shrinking wrapping line, Fully automatic pallet strapping line,Conveyor system and so on. Our company are providing one-stop purchase expereinces for customers. Our productions have beening exported to Europe, North America, the Middle East, Southeast Asia and more than 30 other Countries.

FAQ

1: Are you a factory or trading company?

A: As the pictures I show you in above, located in Changzhou city,we are the factory and our mainly products is: Auto capping machine, Auto labeling machine, and some semi-auto machine,also we can make production line based on your requirements.

2:What's the payment terms?

A: TT transfer,L/C and other payment methods if it is convenient for you.

3:What's the warranty of your equipment?

A:1 year warranty on the machine core after receipt check upon delivery. And we will comprehensively provide you all kinds of technical support service in after-sales.We test every machine manually to make sure they are in good condition before they are sent to your place.

4:What is the service?

7 days 24 hours on line service,engineer overseas service is also available if necessary.

5:What's your advantage? Why we choose you?

A1: We have the most professional techniques and team, we are able to customiz machines according to the customer requirements,which is hardly acquired from other suppliers.

A2:We are a professional manufacturer and warmly welcome clients from worldwide to visit our factory and cooperate with us.

In order to meet the growing international demand, our company is looking for motivated agents to promote products all over the world. If you are interested in a partnership, please contact us and we will contact you as soon as possible.

Please don't hesitate to send us an inquiry for any other questions ,We will come back soon with proper solution.

Hot Searches