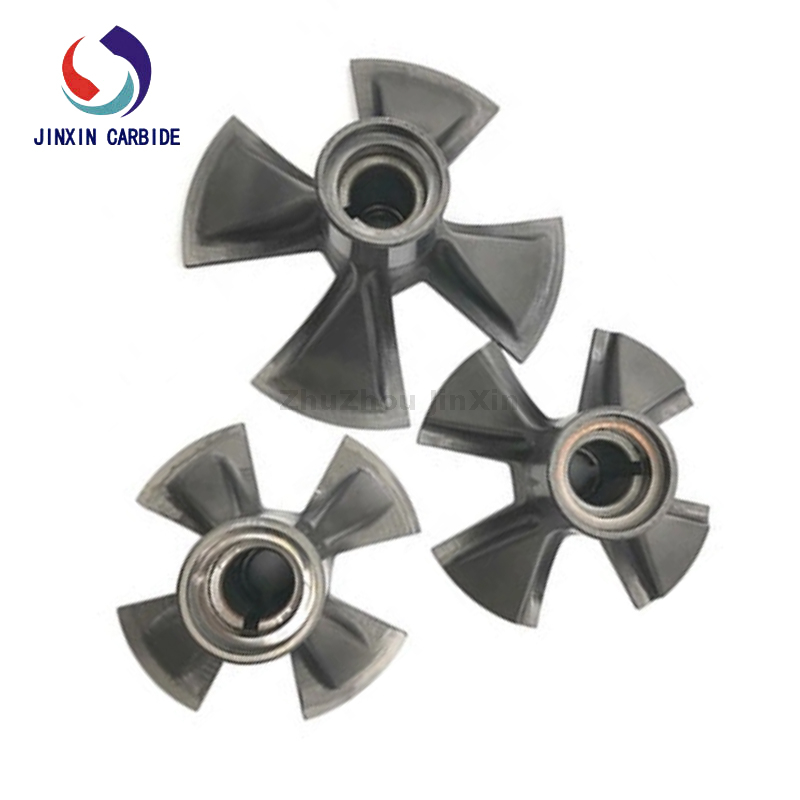

Tungsten carbide rotors and stators are critical components used in various industries, including the oil and gas industry. These

components are known for their exceptional hardness, wear resistance, and durability, making them ideal for applications where

abrasive and corrosive materials are encountered.

Tungsten carbide rotors and stators can be incorporated into drilling tools such as mud motors and positive displacement motors to

provide wear resistance and extend the tool's lifespan.

- Product Details

- {{item.text}}

Quick Details

-

shape:

-

Special-shaped

Quick Details

-

Weight (KG):

-

1

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

jx

-

shape:

-

Special-shaped

Oil Industry Tungsten Carbide Rotors and Stators

.

Working principle of tungsten Rotors And Stators

:

The inclinometer pulse generator is inserted into the current limiting ring through the control (mushroom head) gap to change the

annulus cross-sectional area therebetween. The mud pressure flowing in the drill pipe is changed to form a positive mud pressure

pulse to realize signal transmission. The mud pressure flowing in the drill pipe is changed to form a positive mud pressure pulse

to realize signal transmission. The pulse generator is driven by an electromagnetic mechanism to control a small control valve,

thereby changing the pressure contrast of the upper and lower end faces of the piston. Then use the pressure generated by the mud

flow to push the piston up and down, and the lifting rod (mushroom head) is intermittently inserted into the restrictor ring to

form a positive mud pressure pulse.

annulus cross-sectional area therebetween. The mud pressure flowing in the drill pipe is changed to form a positive mud pressure

pulse to realize signal transmission. The mud pressure flowing in the drill pipe is changed to form a positive mud pressure pulse

to realize signal transmission. The pulse generator is driven by an electromagnetic mechanism to control a small control valve,

thereby changing the pressure contrast of the upper and lower end faces of the piston. Then use the pressure generated by the mud

flow to push the piston up and down, and the lifting rod (mushroom head) is intermittently inserted into the restrictor ring to

form a positive mud pressure pulse.

The use of tungsten carbide rotors and stators in the oil industry helps improve the efficiency and reliability of various

equipment and processes. These components can withstand the harsh operating conditions encountered in oil and gas exploration,

production, and processing, ultimately reducing downtime and maintenance costs.

equipment and processes. These components can withstand the harsh operating conditions encountered in oil and gas exploration,

production, and processing, ultimately reducing downtime and maintenance costs.

Hot Searches