* Sensors

* MEMS and wafers

* LEDs

* Elastomer components

* Medical devices and components

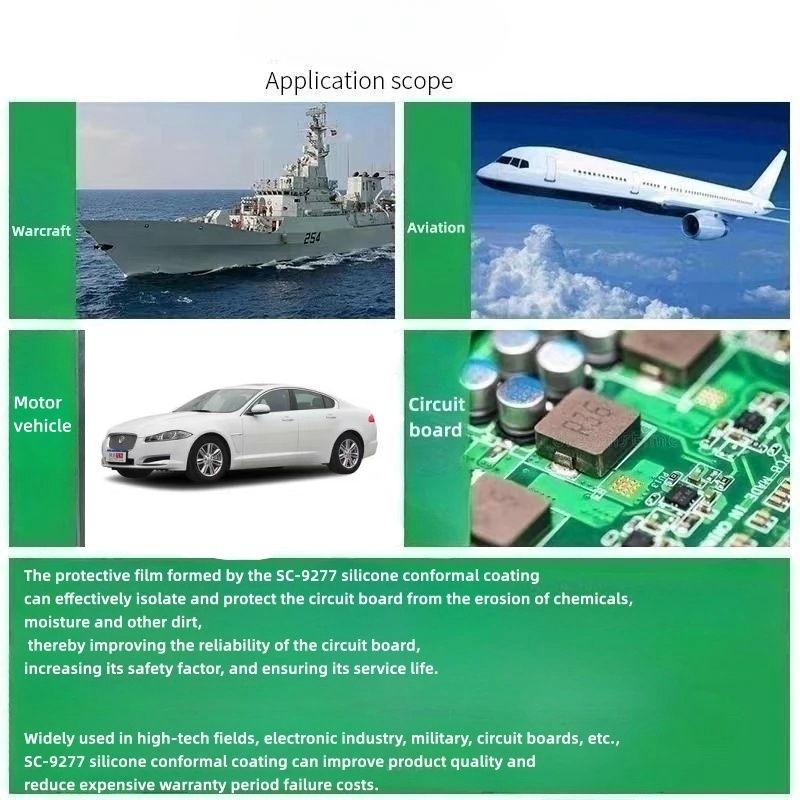

* Motor components