RICHI MLZH-Series

Hay Cubes Pellet Machine

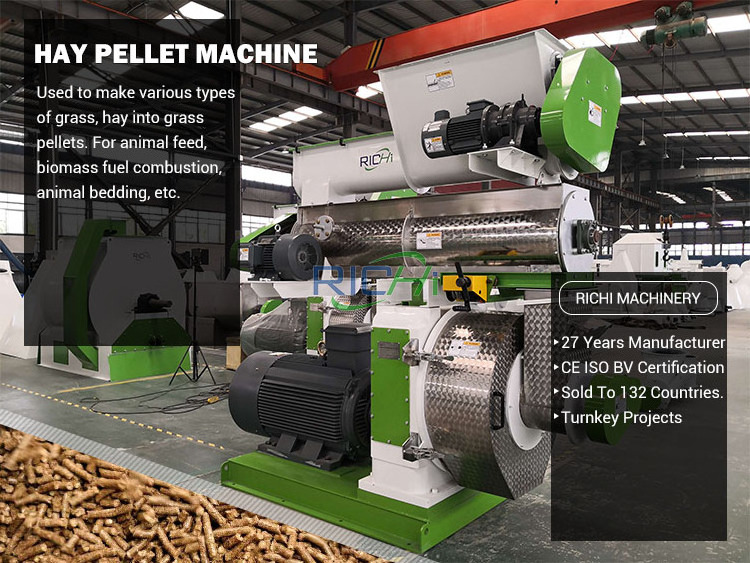

can make grass, straw, pasture, alfalfa, etc into 6~12mm or other size grass pellets.

Grass pellets have a variety of uses such as: as animal feed, as biofuel pellet etc.

The working principle is: the raw material is pressed by the ring die and the pressing roller, and is compressed into grass pellets in the pressing hole on the ring die.