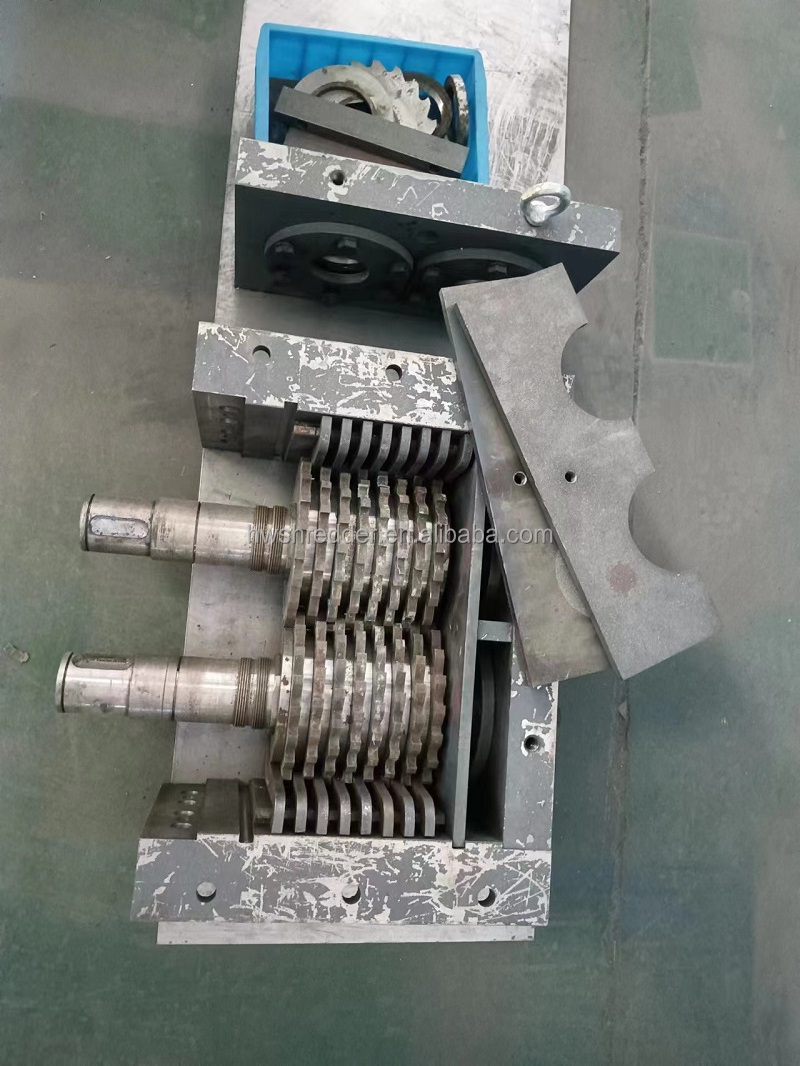

Main shaft is driven by a gear reducer, which runs smoothly, has low noise and large torque;

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hongwang

-

Voltage:

-

220V/380V/415V/600V or customized

-

Dimension(L*W*H):

-

720*720*1100mm

-

Power (kW):

-

3

-

Weight (T):

-

0.32

-

Material:

-

Steel Iron plastic shredder machine

-

Motor power:

-

3kw

-

Crushing material:

-

General Plastic Materials

-

Application:

-

Recycled Industry

Quick Details

-

Max.Production Capacity (kg/h):

-

150

-

Place of Origin:

-

Shanghai, China

-

Production Capacity (kg/h):

-

20 - 150 kg/h, 20-100 kg/h

-

Brand Name:

-

Hongwang

-

Voltage:

-

220V/380V/415V/600V or customized

-

Dimension(L*W*H):

-

720*720*1100mm

-

Power (kW):

-

3

-

Weight (T):

-

0.32

-

Material:

-

Steel Iron plastic shredder machine

-

Motor power:

-

3kw

-

Crushing material:

-

General Plastic Materials

-

Application:

-

Recycled Industry

Product Overview

Single shaft shredders feature:

1. Can be shredded for large volume items (machine head material, thick wall and large diameter plastic pipe), roll film, paper, fiber, film and even large hollow materials;

2. Cutterbed and blade on the rotor can be removed to facilitate cleaning, maintenance;

3. Moving knife is installed in a "V" shape, which makes the cutting of the rotating knife uniform, reduces energy consumption and noise during the whole work;

4. Each moving tool has 4 cutting edges, which can be rotated for 90°after wear and can be used continuously without grinding! Low cost of tool change in later stage;

5. Hydraulic pushing, independent power system, firm structure and stable operation;

6. PLC control system;

FEATURES AT A GLANCE

Each fixed tool has two cutting edges, which can be rotated 180 ° after wear and can continue to be used;

PRODUCT SPECIFICATIONS

|

Model

|

HW600

|

HW800

|

HW1000

|

HW1200

|

|

Feeding size(mm)

|

630*985

|

830*1240

|

1030*1440

|

1230*1700

|

|

Rotor OD(mm)

|

300

|

400

|

450

|

500

|

|

Rotating speed(r/min)

|

78

|

78

|

78

|

78

|

|

Fixed blades(pcs)

|

1

|

2

|

2

|

2

|

|

Rotor blades(pcs)

|

39

|

51

|

63

|

81

|

|

Hydraulic power(kw)

|

2

|

3

|

4

|

4

|

|

Main power(kw)

|

22

|

37

|

55

|

75

|

|

Output(kg/h)

|

500-700

|

700-1000

|

900-1100

|

1000-1500

|

|

Output size(mm)

|

30-100

|

30-100

|

30-100

|

30-100

|

|

Dimensions(mm)

|

2000*1410*2100

|

2430*1720*2480

|

2880*2180*2570

|

3350*2300*2660

|

|

Weight(kg)

|

3500

|

4500

|

6100

|

7800

|

PRODUCT CONFIGURATION

Forged blade, annealed & heat-treated

Copper motor reduces consumption

Low noise and long lifetime gearbox

SALES AND SERVICE NETWORK

Successful Project

Project in Italy

Project in

Philippines

Project in Russia

Hot Searches