- Product Details

- {{item.text}}

Quick Details

-

Rated Voltage:

-

0~440VAC/VDC

-

Working Life:

-

15Million Revs

-

Rotating Speed:

-

200RPM

-

Working Temperature:

-

-30℃~80℃

-

Operating Humidity:

-

0~85% RH

-

Contact Material:

-

Precious Metal

-

Housing Material:

-

Aluminium Alloy

-

Dielectric Strength:

-

500VAC@50Hz,60s

-

Res Noise:

-

<0.01Ω

-

Protection grade:

-

IP51

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Moflon

-

Model Number:

-

MB250

-

Rated Voltage:

-

0~440VAC/VDC

-

Working Life:

-

15Million Revs

-

Rotating Speed:

-

200RPM

-

Working Temperature:

-

-30℃~80℃

-

Operating Humidity:

-

0~85% RH

-

Contact Material:

-

Precious Metal

-

Housing Material:

-

Aluminium Alloy

-

Dielectric Strength:

-

500VAC@50Hz,60s

-

Res Noise:

-

<0.01Ω

-

Protection grade:

-

IP51

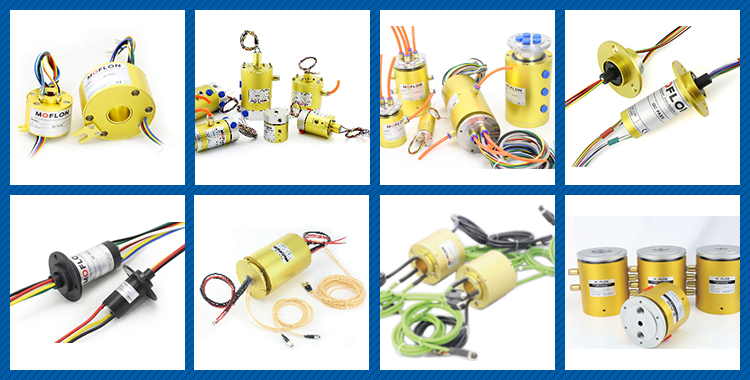

Why Choose Us

Welcome to

Sh

enzhen Moflon Technology Co., Ltd.

An industry leading manufacturer supplying slip rings and rotary unions to companies, contractors, and other end-users.

Here at MOFLON, we have the privilege to work with and provide high perforamce slip ring solutions to some of the largest and most successful companies in the all kinds of Industry.

Let the team at Moflon prove their value in the successful launch of your next critical project.

Products Description

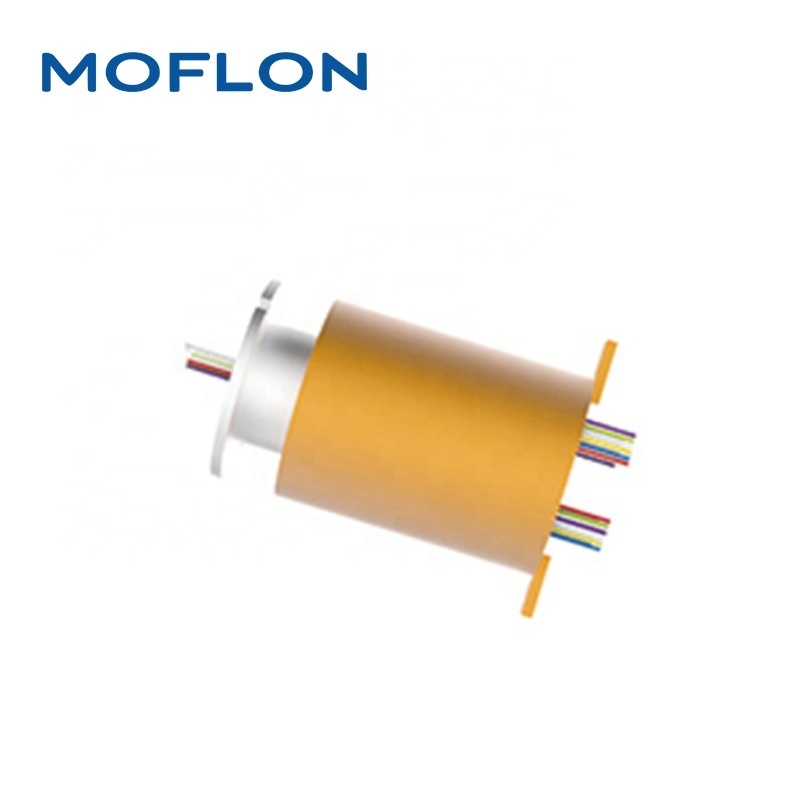

MB series Industry Bus Slip Rings

Industry bus slip ring is specially designed for various industrial bus transmission, supporting various bus, such as Profibus,CanBUS,CANOPEN,DeviceNET and son on. It can combine with digital/analog video, digital audio, Gigabit Ethernet, temperature, weight sensor signal and all kinds of power signals.

Features

* MB series slip rings can support Profibus, EtherCAT,CanBUS, CANOPEN,

* DeviceNET, CC-LINK, ProfiNET, etc.

* High rate industry field-bus slip ring

* Super-strong capacity of anti-interference.

* Special shield for inner structure

* Guarantee 100% communication without dead point

* Specially designed for high rate data and error free transmission

* Invention Patent

* Contact parts adopt rare metals and hard gold plating treatment process, guaranteeing wear-resisting and oxidation resistance, which ensures long working life

* DeviceNET, CC-LINK, ProfiNET, etc.

* High rate industry field-bus slip ring

* Super-strong capacity of anti-interference.

* Special shield for inner structure

* Guarantee 100% communication without dead point

* Specially designed for high rate data and error free transmission

* Invention Patent

* Contact parts adopt rare metals and hard gold plating treatment process, guaranteeing wear-resisting and oxidation resistance, which ensures long working life

|

MB Series Models

|

|

|

|

|

||||

|

Model#

|

ID(mm)

|

OD(mm)

|

Bus Channel Number

|

Power 10A/signal number

|

||||

|

MB120

|

12.7

|

56

|

1~4

|

1~48

|

||||

|

MB250

|

25.4

|

86

|

1~4

|

1~72

|

||||

|

MB250F

|

0

|

86

|

1~4

|

1~72

|

||||

|

MB380

|

38.1

|

99

|

1~4

|

1~72

|

||||

|

MB500

|

50

|

120

|

1~4

|

1~96

|

||||

MB250 Series

Industrial Field Bus Slip Ring with Through Bore Electrical Rotary Joints MB series

MB250 series is our standard series integral and precise industry bus slip ring , with bore size 25.4mm (1/2’’, suitable for <=25.4mm), can support Profibus,EtherCAT, CanBUS, CANOPEN, DeviceNET, CC-LINK, ProfiNET, etc.

Note: If required through bore<25.4mm,this can be solved by adding a sleeve inside the bore.

High Speed Transmission

Specailly designed for high speed data and error free data communication transmission.

MOFLON Strength

How a high-quality lever slip ring supplied by Moflon

A well-known manufacturer incl. R&D/Production/Sales, with 7,000㎡ own factory and over 300 employees. Main staffs have over 10 years of related technical experiences

Since founded. We believe quality and innovation are the life of our enterprise. We pay high attention to R&D, Raw Materials, Production, QC and After Sales Service for providing good products and services.

R & D

Moflon has a strong R & D team with 20 engineers over 10 experiences in this industry, have successfully developed more than 10,000 projects .

Production Capability

We have our own plastic injection factory and machining center, all the critical components made in-house, there are more than assemlby lines in our factory , which guarantee raw material internal control and the fast supply for your desired silp ring.

QA & QC System

There are more 15 steps QC process for your each slip rings in here.

Moflon is the only chinese comapny with level-5 slip ring testing laboratary.

Application & Project

Service Process

Success in project using slip ring technology means overcoming challenges in every area of your business. Challenges in design, production, cost control, delivery—the list goes on.

Moflon has been helping customers face their most pressing slip ring challenges for over 30 years. And we’ve revolutionized virtually every aspect of how high perfomance slip rings are designed, developed, and produced.

We can help you achieve improved performance while reducing your overall costs

Exhibition & Customer

Packaging & Shipment

FAQ

How to customize the slip rings?

1. What kind of media do you wanna to transmit?

A: Electricity, gas, Ethernet, fiber optic or hybrid slip rings.

2. For electricity, the details should be provided as below:

a. Total wires? The max current of each wire?

b. How many circuits for signal? The frequency and signal type?

c. Whether the signal is sensitive, if sensitive, does it need shielded?

3. For gas or liquid, the details should be provided as below:

a. What's gas do you need to transmit? Is air?

b. How much pressure?

c. What's size of each port? is G1/4"?

d. What is the maximum torque of slip ring that you can accept?

e. How to install? shaft mounting? flange mounting? end of shaft mounting?

4. For Ethernet, the details should be provided as below:

a. 1000M or 100M?

b. Total wires? The max current of each wire?

c. How many circuits for signal? The frequency and signal type?

d. Whether the signal is sensitive, if sensitive, does it need shielded?

5. For fiber optic, the details should be provided as below:

a. Total wires?

b. Connector type?

c. Type of fiber optic?

d. If need electricity or signals, please answer the Q1.

6. What's the rotating speed and how long does it work continuously per day?

7. May i know the application area(working environment)of the slip ring first?

A: Electricity, gas, Ethernet, fiber optic or hybrid slip rings.

2. For electricity, the details should be provided as below:

a. Total wires? The max current of each wire?

b. How many circuits for signal? The frequency and signal type?

c. Whether the signal is sensitive, if sensitive, does it need shielded?

3. For gas or liquid, the details should be provided as below:

a. What's gas do you need to transmit? Is air?

b. How much pressure?

c. What's size of each port? is G1/4"?

d. What is the maximum torque of slip ring that you can accept?

e. How to install? shaft mounting? flange mounting? end of shaft mounting?

4. For Ethernet, the details should be provided as below:

a. 1000M or 100M?

b. Total wires? The max current of each wire?

c. How many circuits for signal? The frequency and signal type?

d. Whether the signal is sensitive, if sensitive, does it need shielded?

5. For fiber optic, the details should be provided as below:

a. Total wires?

b. Connector type?

c. Type of fiber optic?

d. If need electricity or signals, please answer the Q1.

6. What's the rotating speed and how long does it work continuously per day?

7. May i know the application area(working environment)of the slip ring first?

Hot Searches