- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dingbo

-

Voltage:

-

380V 50Hz 3phases(customized)

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

9000mm*1200mm*800mm

-

Weight:

-

3500 kg

-

Control system:

-

PLC(imported Brand)

-

Color:

-

Client's Request

-

Feature:

-

Automation

-

Usage:

-

Building Projects

-

Raw material:

-

PPGI PPGL GI GL

-

Cutter Material:

-

Cr12Mov

-

Roller Station:

-

13 Stations

-

Thickness:

-

0.4-0.8mm

-

Roller material:

-

45# Steel

-

Service:

-

1 Year Guarantee

Quick Details

-

Marketing Type:

-

New Product

-

Production Capacity:

-

10-15m/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Dingbo

-

Voltage:

-

380V 50Hz 3phases(customized)

-

Power:

-

5.5kw

-

Dimension(L*W*H):

-

9000mm*1200mm*800mm

-

Weight:

-

3500 kg

-

Control system:

-

PLC(imported Brand)

-

Color:

-

Client's Request

-

Feature:

-

Automation

-

Usage:

-

Building Projects

-

Raw material:

-

PPGI PPGL GI GL

-

Cutter Material:

-

Cr12Mov

-

Roller Station:

-

13 Stations

-

Thickness:

-

0.4-0.8mm

-

Roller material:

-

45# Steel

-

Service:

-

1 Year Guarantee

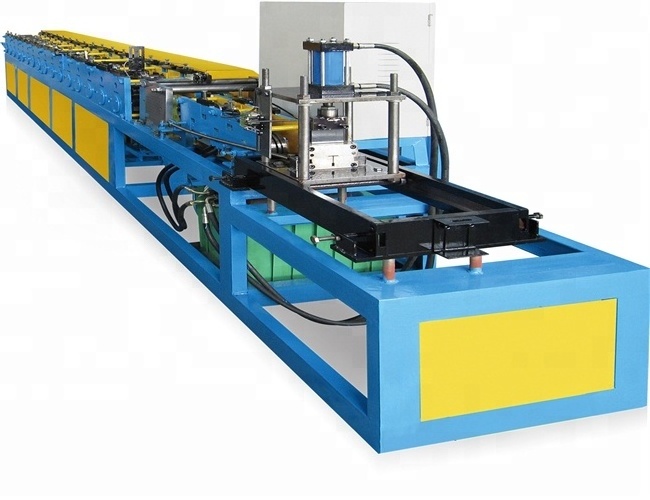

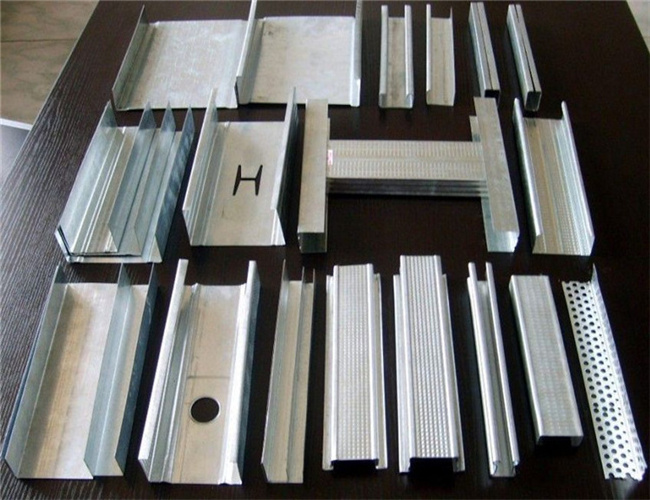

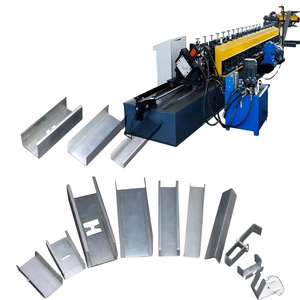

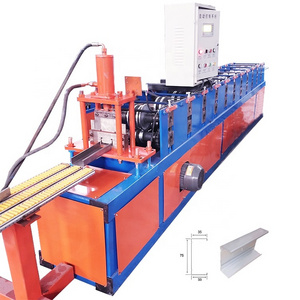

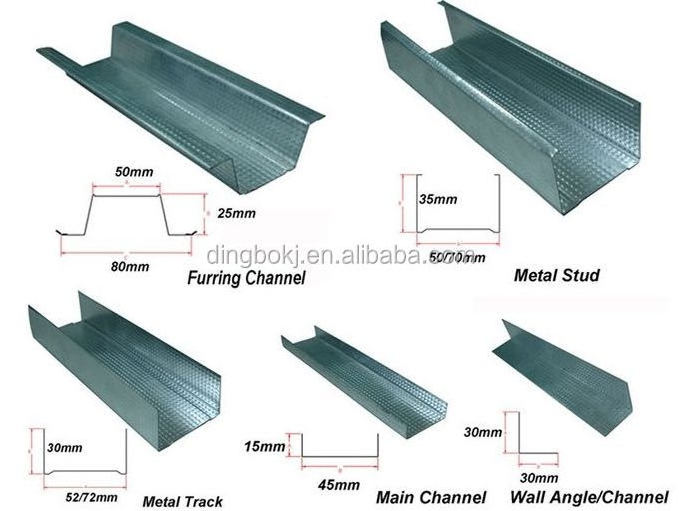

Stud and track roll forming machine

Product Descriptions

Stud tracks are widely used in luxury villas, high-end hotels, office buildings and shopping malls. It is sturdy, durable, and highly resistant to corrosion. It is also popular with construction units and construction units in terms of price, reducing the quality concerns of the project during construction, and frequent maintenance due to material quality problems during use. Greatly reduce the construction cost and various troubles caused by maintenance during use.

Version to design

Working Flow

Decoiler -- Feeding -- Straighten -- Punching --Roll forming -- Shear -- Output

Product Parameters

|

|

Items |

Specifications |

|

Material of coil |

Thickness |

0.3-1mm galvanized steel |

|

De-coiler |

Weight |

3 ton manual |

|

Forming system |

Rolling Speed |

0-15m/min 15-45m/min (Depending on the customer) |

|

Embossing |

At sides |

|

|

Roller Stations |

About 13 stations forming |

|

|

Roller Material |

Cr40 Steel with quenching |

|

|

Shaft Material |

45# Steel Diameter 60mm shaft |

|

|

Motor Power |

5.5 kw |

|

|

Hydraulic cutting Power |

3 kw |

|

|

Sizes adjustment |

automatic by PLC |

|

|

Cutting system |

Material of cutting |

CR12 with quench treatment |

|

Hardness |

HRC58-62 |

|

|

Tolerance |

+-1.5mm |

|

|

Cutting blade |

3 pieces of cutting blade |

|

|

Electrical control system |

Electric Source |

380V, 50HZ,3 phase |

|

Control System |

PLC |

|

|

|

Weight |

About 3 tons |

|

|

Way Of Drive |

1 inch single chain |

|

|

Size of machine |

Length 5500mm* Width 600mm*Height 800m |

Main Components

|

3 ton passive de-coiler |

1 set |

|

Main roll forming machine |

1 set |

|

Punching device |

1 set |

|

Cutting device |

2 sets |

|

PLC Control box |

1 unit |

|

Hydraulic station |

1 unit |

|

Out table |

2 units |

|

Safety cover |

1 unit(Optional) |

Pictures