- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

Hubei, China

-

Spare Parts Type:

-

CO2 LASER TUBE

-

Weight (KG):

-

30 KG

Product Description

*

*

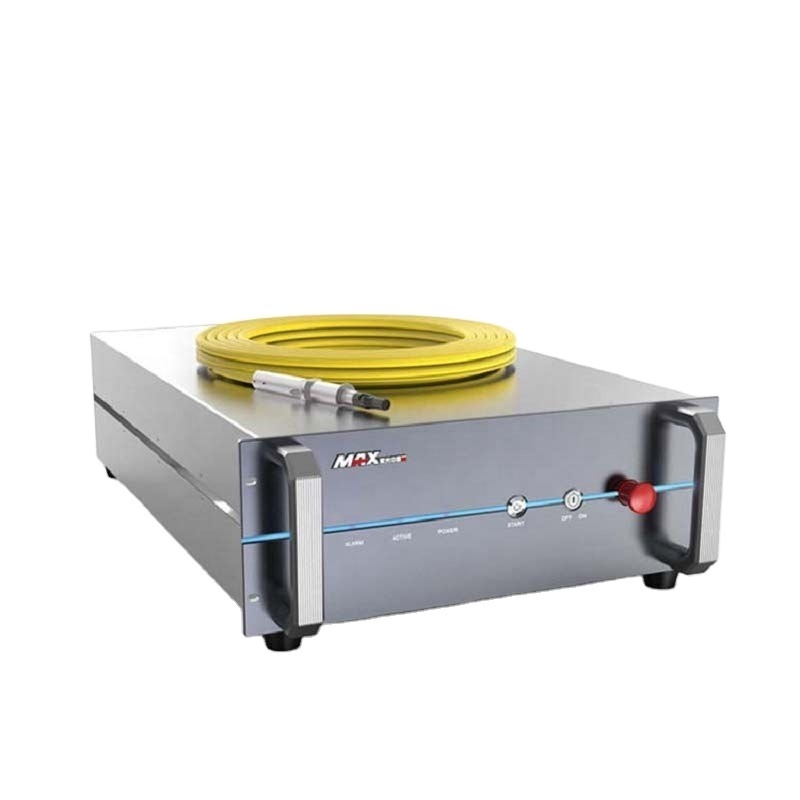

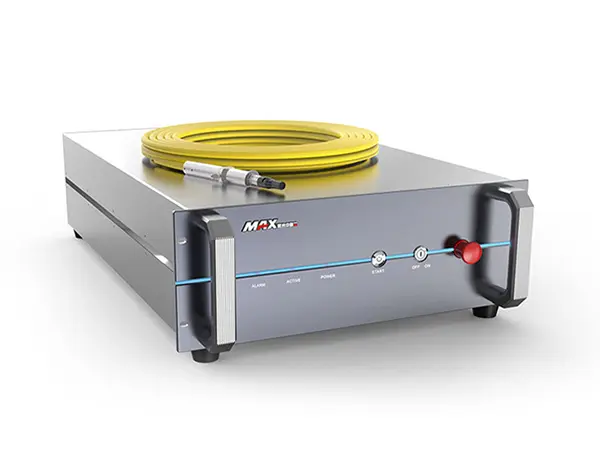

CW MAX Fiber laser Source

DESCRIPTION

The MAX laser has higher photoelectric conversion efficiency (>30%), better and more stable beam quality, and stronger anti-high anti-reflective ability to ensure a more stable and precise cutting effect in thick plate cutting. The product is suitable for a

variety of applications: cutting,...

* The MAX laser has higher photoelectric conversion efficiency (>30%), better and more stable beam quality, and stronger anti-high anti-reflective ability to ensure a more stable and precise cutting effect in thick plate cutting.

* The product is suitable for a variety of applications: cutting, welding, drilling, medical device processing, etc. The cut plate has a narrow slit and a bright cross-section.

* The product is suitable for a variety of applications: cutting, welding, drilling, medical device processing, etc. The cut plate has a narrow slit and a bright cross-section.

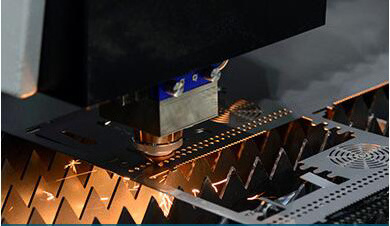

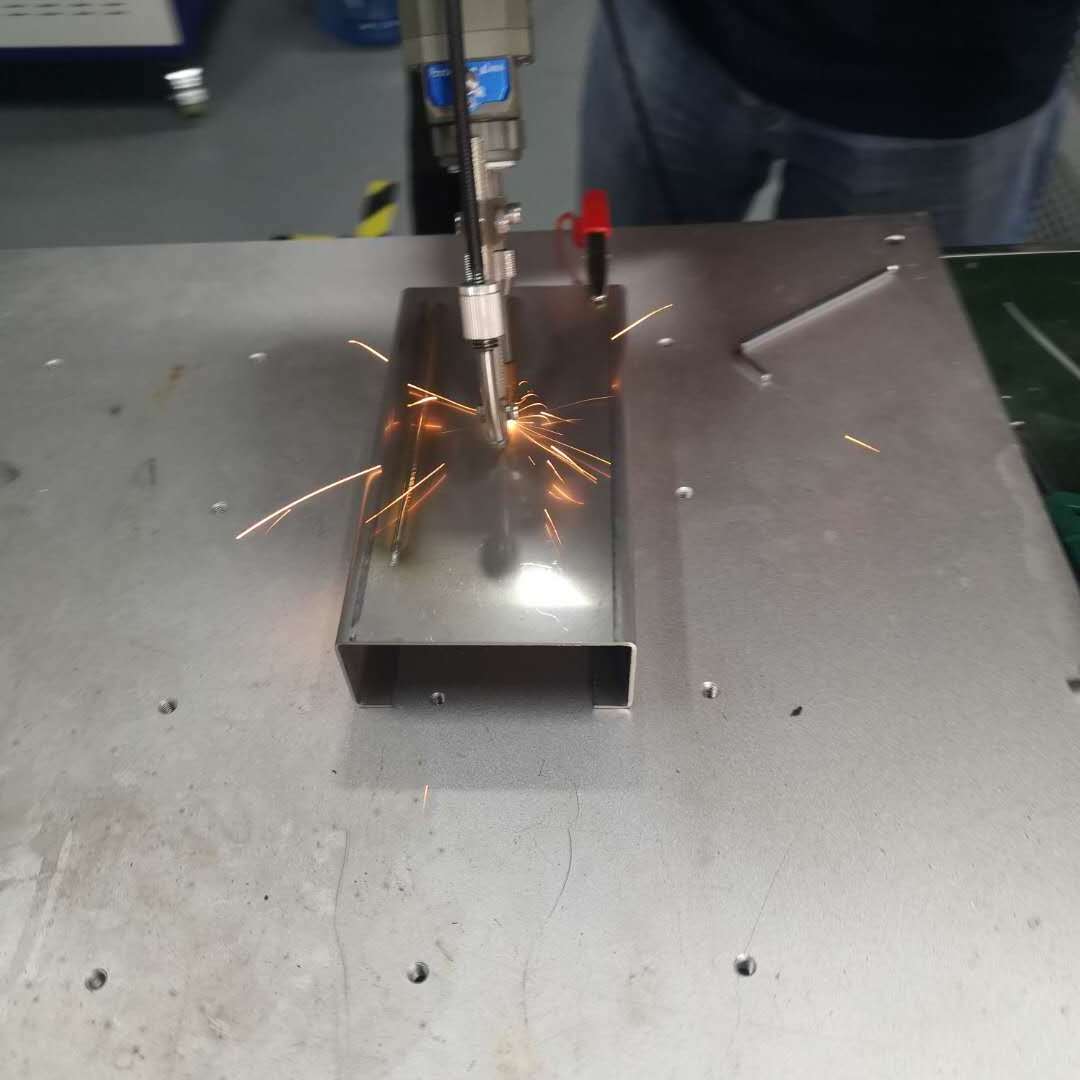

Application

Laser cutting

Laser welding

Title goes here.

Specification

|

model

|

MFSC-1000W

|

MFSC-1500W

|

MFSC-2000W

|

MFSC-3000W

|

MFSC-4000W

|

|||||

|

Optical properties

|

|

|

|

|

|

|||||

|

Output Power(W)

|

1000

|

1500

|

2000

|

3000

|

4000

|

|||||

|

Operating mode

|

Continuous / pulse

|

|

|

|

|

|||||

|

Polarization state

|

random

|

|

|

|

|

|||||

|

Power adjustment range (%)

|

10~100

|

|

|

|

|

|||||

|

Center wavelength (nm)

|

1080(±10)

|

|

|

|

|

|||||

|

Spectral bandwidth 3dB(nm)

|

3~5

|

|

|

|

|

|||||

|

Short-term power stability(%)

|

±1

|

|

|

|

|

|||||

|

Short-term power stability(%)

|

±2

|

|

|

|

|

|||||

|

Beam quality M²

|

1.3(20u-QBH Output )

|

|

|

|

|

|||||

|

|

2.8(50u-QBH Output )

|

|

|

|

|

|||||

|

Laser on time (μs)

|

50~100

|

50~80

|

50~80

|

50~80

|

50~80

|

|||||

|

Laser off time (μs)

|

50~100

|

30~50

|

30~50

|

30~50

|

30~50

|

|||||

|

Modulation frequency(KHz)

|

20

|

20~50

|

20~50

|

20~50

|

20~50

|

|||||

|

Indicating red light power(μW)

|

150

|

|

|

|

|

|||||

|

Output optical cable parameters

|

|

|

|

|

|

|||||

|

output method

|

standard QBH(LOC)

|

|

|

|

|

|||||

|

Fiber optic cable length(m)

|

15/20

|

|

|

|

|

|||||

|

Output fiber core diameter(μm)

|

50(30/100 Optional )

|

|

|

|

|

|||||

|

Optical fiber cable bending radius(mm)

|

200

|

|

|

|

|

|||||

|

Electrical parameters

|

|

|

|

|

|

|||||

|

Operating Voltage(VAC)

|

220

|

220

|

380

|

380

|

380

|

|||||

|

Rated power consumption(KW)

|

3.5

|

6

|

8

|

12

|

15

|

|||||

|

Other parameters

|

|

|

|

|

|

|||||

|

Working temperature(℃)

|

10~40

|

|

|

|

|

|||||

|

Storage temperature(℃)

|

-10~60

|

|

|

|

|

|||||

|

Relative humidity of working environment(%)

|

10~85

|

|

|

|

|

|||||

|

Cooling method

|

Water cooling

|

|

|

|

|

|||||

|

size(MM)

|

800×482.6×193.2

|

800×482.6×193.2

|

950×482.6×193.2

|

640×1000×700

|

640×1000×700

|

|||||

|

weight(KG)

|

50(±3)

|

68(±3)

|

88(±3)

|

200(±20)

|

200(±20)

|

|||||

Product Photo

Application Of Single Module CW Fiber Laser

※Precision Cutting

※Metal Welding

※Sheet Metal Piercing

※Metal Carving

※Surface Treatment

※3D Printing/Rapid Prototyping

Packing & Delivery

1. Anti-collision package edge: All parts of the machine are covered with some soft materials, mainly the use of pearl wool

2. Fumigation wooden box: Our wooden box is fumigated, do not need to check the wood, saving the transport time. 3.Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust. The outermost is a wooden box with a fixed template.

Hot Searches