- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

TX15015

-

Material:

-

A356

-

Design software:

-

Pro-E, UG

-

Surface treatment:

-

Polish. Etched. Texture

-

Customized:

-

Customized

-

Process:

-

Sand Casting

-

Runner:

-

Hot Runner

-

Surface Finish Process:

-

Sand Blasting or Polishing

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

OEM

-

Model Number:

-

TX15015

-

Material:

-

A356

-

Design software:

-

Pro-E, UG

-

Surface treatment:

-

Polish. Etched. Texture

-

Customized:

-

Customized

-

Process:

-

Sand Casting

-

Runner:

-

Hot Runner

-

Surface Finish Process:

-

Sand Blasting or Polishing

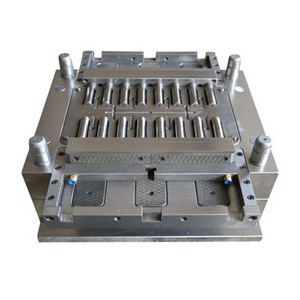

Polyethylene Rotational Molding Mould Stair Cup Support Mold

The rotational molding model mould

1. Mould shaping mode: Sand casting

2. Mould material: Aluminum A356

3. Mould surface treatment: Sand blasting

4. Mould thickness: 8-10 mm

5. Mould for: Rotational moulding production

Process: Pouring liquid aluminum into a sand cavity creates the mould, then the mould is polished and/or textured to your specifications, this process takes a meticulous eye for detail. The mould cavities are then fit together. A steel frame is constructed and mounted to the mould. After the framing and fitting of the mould are completed, we will produce samples to test the new mould.

1. Mould shaping mode: Sand casting

2. Mould material: Aluminum A356

3. Mould surface treatment: Sand blasting

4. Mould thickness: 8-10 mm

5. Mould for: Rotational moulding production

Process: Pouring liquid aluminum into a sand cavity creates the mould, then the mould is polished and/or textured to your specifications, this process takes a meticulous eye for detail. The mould cavities are then fit together. A steel frame is constructed and mounted to the mould. After the framing and fitting of the mould are completed, we will produce samples to test the new mould.

workshop photo

CNC porcess

Additional Info

Packing:

Wooden Case Package

Any questions, please feel free to contact us.

Hot Searches