- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

160

-

Weight (KG):

-

14000

-

Application:

-

Recycle Waste Metal

-

Name:

-

Metal Crusher Machine

-

Raw material:

-

Used Metal Material

-

Function:

-

Recycle Metal

-

Final product:

-

Request

-

Advantage:

-

High Efficiency Low Energy

-

After-sales Service Provided:

-

3 Year

-

Color:

-

Customer's Requirement

-

Hammer head material:

-

High Manganese Alloy Steel

-

Machine Type:

-

Support Customization

Quick Details

-

Place of Origin:

-

Henan, China

-

Marketing Type:

-

Hot Product 2024

-

Brand Name:

-

Center Machine

-

Power (kW):

-

160

-

Weight (KG):

-

14000

-

Application:

-

Recycle Waste Metal

-

Name:

-

Metal Crusher Machine

-

Raw material:

-

Used Metal Material

-

Function:

-

Recycle Metal

-

Final product:

-

Request

-

Advantage:

-

High Efficiency Low Energy

-

After-sales Service Provided:

-

3 Year

-

Color:

-

Customer's Requirement

-

Hammer head material:

-

High Manganese Alloy Steel

-

Machine Type:

-

Support Customization

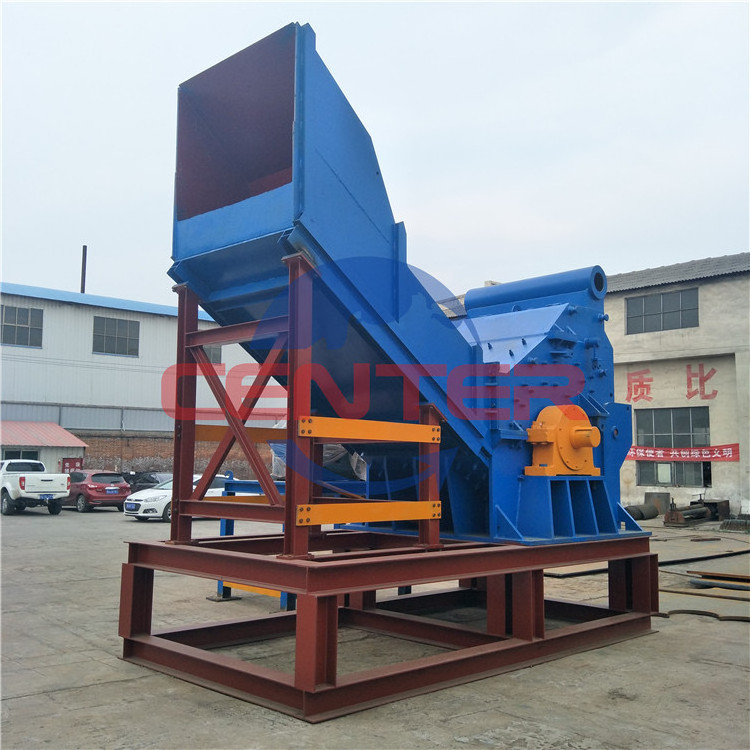

01 Product Description

Product Introduction

Metal crusher is a kind of crushing equipment used to deal with scrap metal, mainly used in the crushing operation of scrap automobiles, waste electrical appliances and light waste aluminum. The crushing material after metal crusher treatment has high density, high purity and basically no impurities. Aluminum factory and other manufacturing enterprises with broken materials to re-melt into new products, low unit energy consumption, high output, comprehensive economy is obvious. Metal crusher is recognized as the ideal equipment for scrap metal treatment.

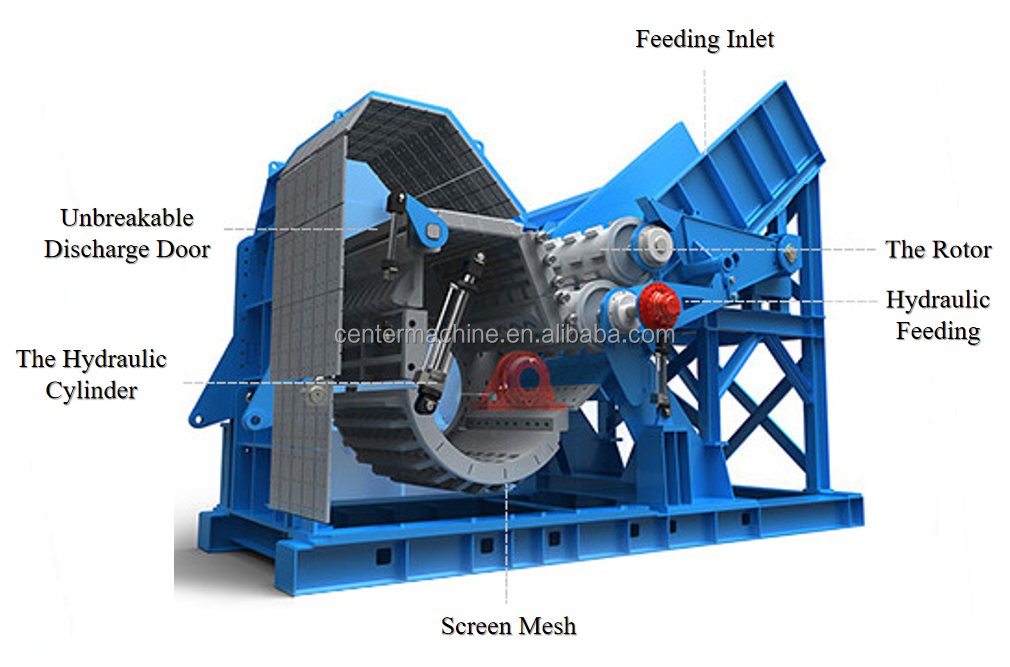

02 Details Images

Unbreakable

Discharge Door

Safety door, unbroken material into the body, can be automatically opened to discharge the machine chamber, protect the host.

The Hydraulic

Cylinder

Hydraulic capping device saves time and labor in maintenance.

Screen Mesh

Movable screen, adjustable hammer and screen clearance, to obtain the expected specifications of crushing material.

Hydraulic

Feeding

The hydraulic feeding device precompresses the material, enlarges the feeding range and improves the production efficiency.

The Rotor

Combined hammer head of swing hammer and ring hammer, crushing and kneading in one, which can significantly remove dirt such as paint and form high-density bulk materials.

Feeding Inlet

Wide inlet, suitable for crushing large volume of raw materials, improve the feeding capacity.

03 More Pictures

04 Product Paramenters

|

Model

|

Input Size(mm)

|

Power(kw)

|

Capacity(t/h)

|

Complete Auxiliary Machinery

|

|

|

|

75

|

1000

|

75

|

1-2

|

Feeding Conveyor 1 Article

Discharge Conveyor 1 Article

Iron Conveyor 1 Article

Impurities Conveyor 1 Article

Magnetic Separation System 1 Set

Dust Removal System 1 Set

Control System 1 Set

Intelligent Visual System 1 Set

Spray System 1 Set

|

1

|

|

|

132

|

1200

|

132

|

2-3

|

|

1

|

|

|

160

|

1300

|

160

|

3-5

|

|

1

|

|

|

200

|

1400

|

200

|

3-6

|

|

1

|

|

|

280

|

1600

|

280

|

4-7

|

|

1

|

|

|

315

|

1600

|

315

|

5-8

|

|

1

|

|

|

450

|

1800

|

450

|

8-12

|

|

1

|

|

|

630

|

1800

|

630

|

10-15

|

|

1

|

|

|

750

|

2000

|

750

|

12-17

|

|

1

|

|

|

900

|

2200

|

900

|

20-25

|

|

|

|

05 Product Application

Raw Materials And End Products

|

Transformer

|

Scrap Aluminum

with Iron

|

Plating

Hangers

|

Broken Bridge Aluminum

|

|

Scrap Iron

|

Engine Oil Filter

|

Aluminium Alloy

|

Aluminum Rotor

|

6.0ur Advantages

Look Forward To Meeting You!

Our company has strict quality management system. There is a quality inspection department. Only products that have passed the test can be delivered. At the same time, the company supports SGS third-party inspection agencies to inspect products and factories. Welcome to visit our company.

7.

Hot Searches