- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220/380/415/420/440V

-

Power:

-

90KW

-

Dimension(L*W*H):

-

29-48*1.5-3.0m

-

Weight:

-

12 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

welded pipe roll forming machine

-

Pipe shape:

-

Rectangle, circle, square

-

productivity:

-

0-80m/min

-

Raw material:

-

Low-carbon Steel

-

safety level:

-

high

-

working length:

-

50m

-

container require:

-

2*40GP

-

Handle person:

-

2-3 persons

-

certificated:

-

CE ISO

Quick Details

-

Pipe Material:

-

Iron

-

Production Capacity:

-

0-90m/min

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHONGTUO

-

Voltage:

-

220/380/415/420/440V

-

Power:

-

90KW

-

Dimension(L*W*H):

-

29-48*1.5-3.0m

-

Weight:

-

12 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

welded pipe roll forming machine

-

Pipe shape:

-

Rectangle, circle, square

-

productivity:

-

0-80m/min

-

Raw material:

-

Low-carbon Steel

-

safety level:

-

high

-

working length:

-

50m

-

container require:

-

2*40GP

-

Handle person:

-

2-3 persons

-

certificated:

-

CE ISO

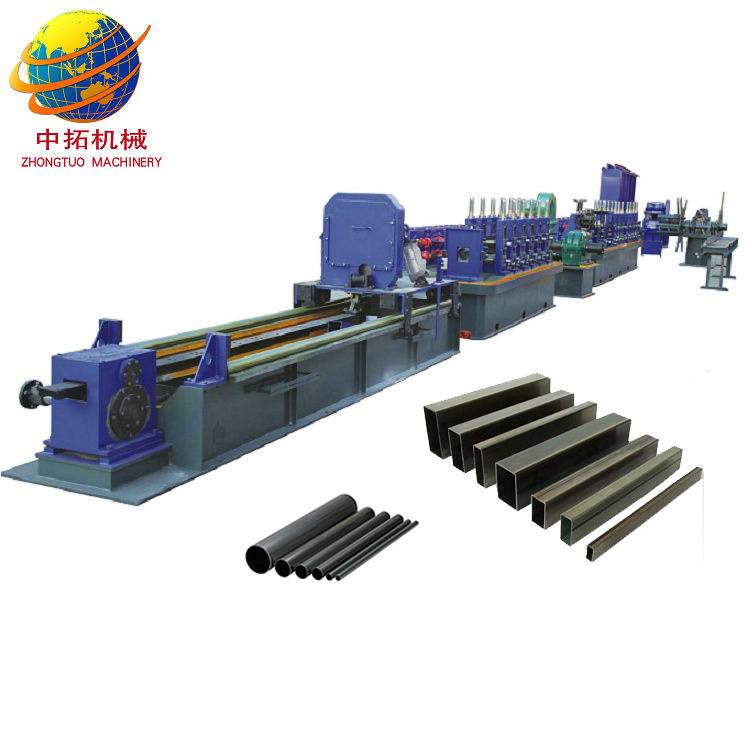

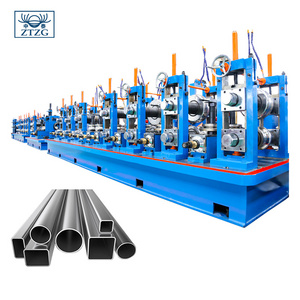

high frequency welded round square pipe making roll forming machine

ZT 5 0 is intended for manufacturing of high frequency straight seam welding tube ,

square tube and special shapes tube of Φ 19 mm-Φ 63.5 mm with thickness of 0. 7 mm– 2.5 mm.

The production line adopts advanced pass technology, PLC automatic control system,

with stable operation, convenient operation and repair, and reached the advanced level in the same industry in the structure and accuracy.

Equipment from the material to tube run out, the speed adjust s according to the tube specification changing .

O.D.:Φ19~Φ63.5 Square and rectangle tube:20*20~ 50*50

Tube wall thickness:round tube0.7~2.5 square tube:0.7~2.0mm

Milling speed:30~90m/min

|

The main type for welded pipe roll forming machine |

|||

|

Machine HG-32 |

Machine HG-50 |

||

|

Wall thickness |

0.4-2.5mm |

Wall thickness |

0.4-2.5mm |

|

Pipe diameter |

10-45mm |

Pipe diameter |

10-45mm |

|

Round pipe |

Max. OD-45mm, Min.OD-10mm |

Round pipe |

Max. OD-45mm, Min.OD-10mm |

|

Square pipe |

Max.-35*35mm, Min.-10*10mm |

Square pipe |

Max.-35*35mm, Min.-10*10mm |

|

Rectangular pipe |

Max.-30*40mm, Min,-10*10mm |

Rectangular pipe |

Max.-30*40mm, Min,-10*10mm |

|

Machine HG-76 |

Machine HG-127 |

||

|

Wall thickness |

0.4-2.5mm |

Wall thickness |

0.4-2.5mm |

|

Pipe diameter |

10-45mm |

Pipe diameter |

10-45mm |

|

Round pipe |

Max. OD-45mm, Min.OD-10mm |

Round pipe |

Max. OD-45mm, Min.OD-10mm |

|

Square pipe |

Max.-35*35mm, Min.-10*10mm |

Square pipe |

Max.-35*35mm, Min.-10*10mm |

|

Rectangular pipe |

Max.-30*40mm, Min,-10*10mm |

Rectangular pipe |

Max.-30*40mm, Min,-10*10mm |

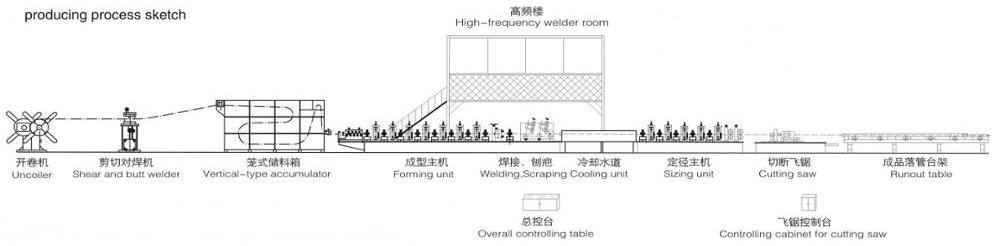

The whole production line work flow like:

Raw material → uncoiling → shearing and butt- welding → a ccumulator →leveling→ mill-forming → high-frequency welding

→ deburring → cooling (water colling) → sizing →straightening → fixed length cutting → run-out table

From the work flow we can see that it's a long production line, need about 50m length and 3m height workshop to start the machine.

We can provide the whole machine units for clients, and make the layout according to client's workshop design.

The normal cutting length will be 6m and 9m, the flying saw can track the pipe and cutting to length with the PLC control command.

Please see some machine units as below:

| the double heads uncoiler | vertical-type accumulator |

|

|

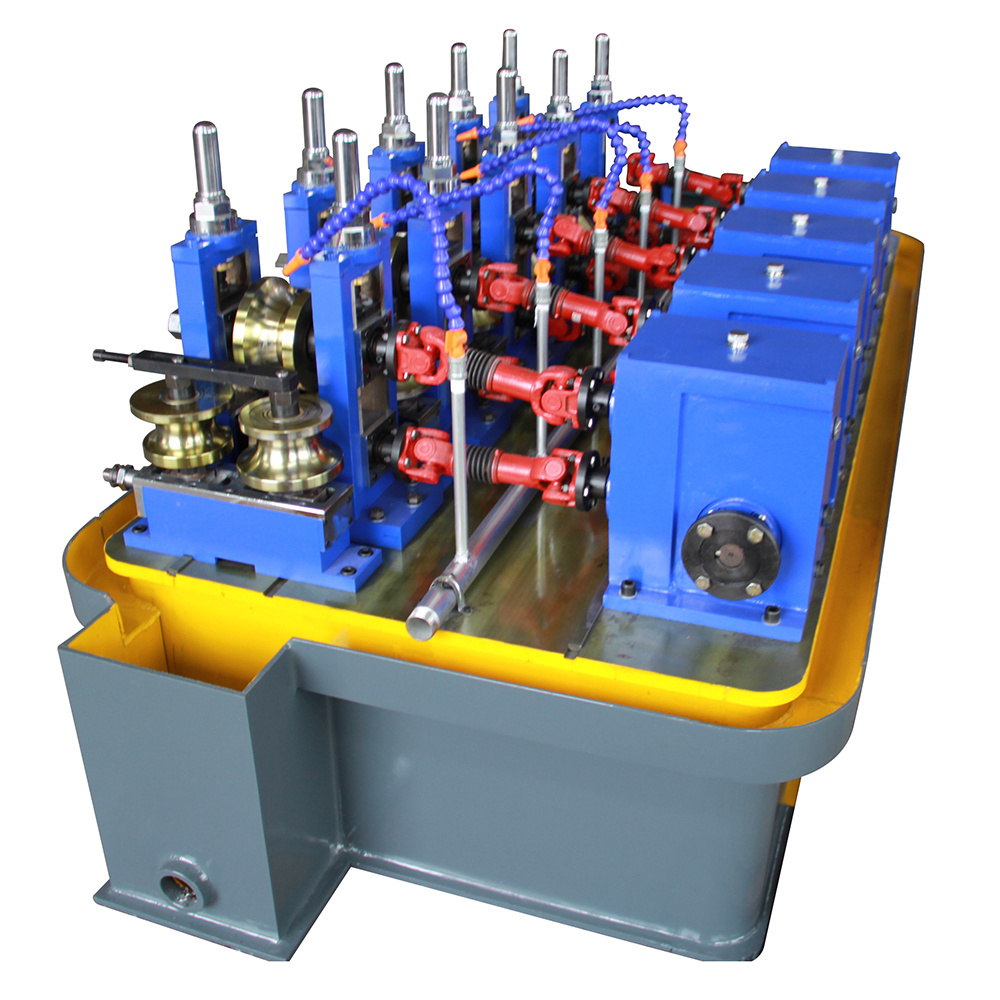

| roll forming machine | sizing forming machine |

|

|

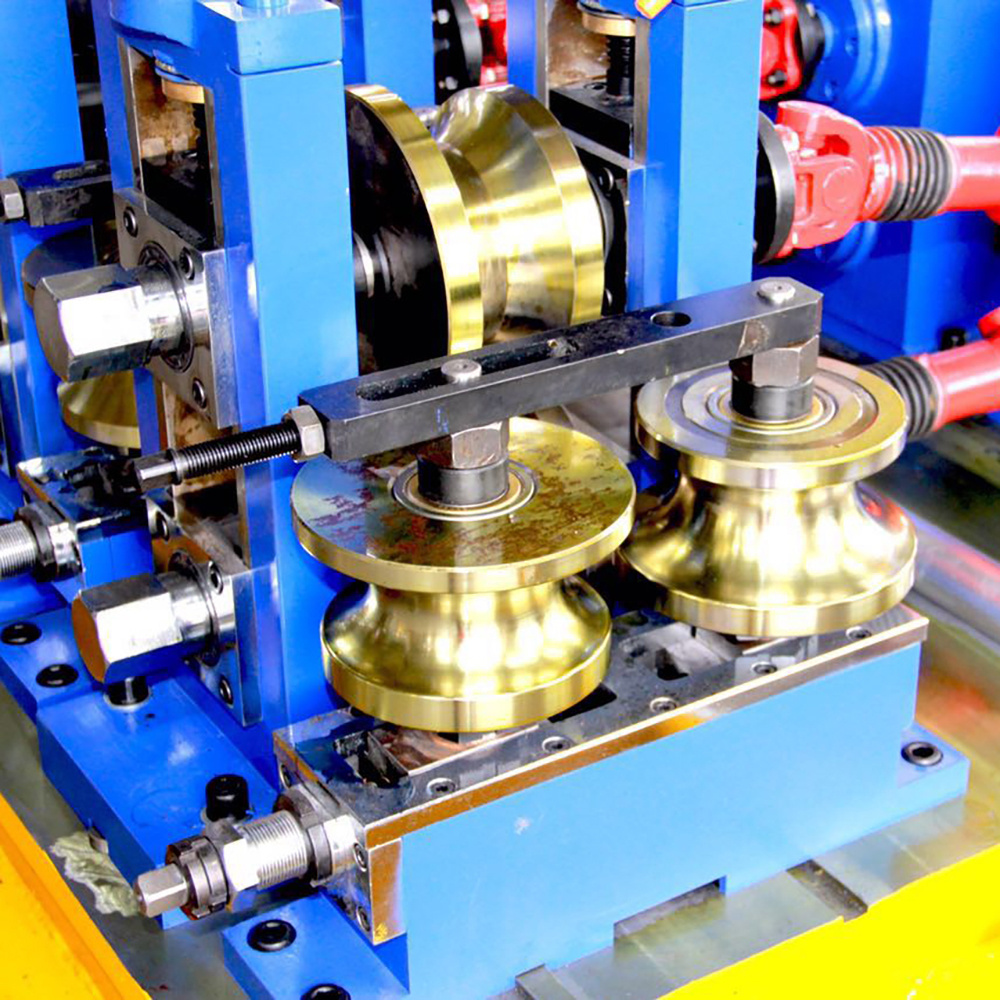

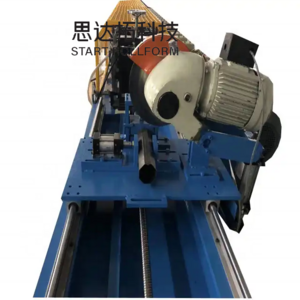

| flying saw cutting system | pipe making roller |

Please noted that the welded pipe machine is with the high frequency unit, during the welding will cause much quantity of heat,

so we need a cooling system for the welding unit. At same time, the rollers also getting hot with long time working,

we will match full set cooling system for the prodcution line.

Because of the high frequency welding, the roll forming machine can not stop before finish work.

The tracking flying saw cutting is very important instead of the hydraulic post cutting.