- Product Details

- {{item.text}}

Quick Details

-

Rated Power:

-

7.5kw

-

Dimension(L*W*H):

-

3880*2150*2000mm

-

Weight (KG):

-

5650 KG

-

Model Number:

-

GSII-L1530-PMAX-85A

-

Plasma Power:

-

Powermax85 USA

-

Gantry type:

-

Table

-

Effective Cutting area(Length):

-

1500mm

-

Effective Cutting area(width):

-

3000mm

-

run speed:

-

4000mm/min

-

Cutting positioning accuracy:

-

±0.5mm/m

-

Surface roughness:

-

Ra≤25μm

-

CNC controller:

-

AI, DST, DWG, DXF, DXP, LAS

-

Servo motor:

-

Software Supports HPRXD and True Hole

Quick Details

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

ACCURL

-

Voltage:

-

380V 220V Optional

-

Rated Power:

-

7.5kw

-

Dimension(L*W*H):

-

3880*2150*2000mm

-

Weight (KG):

-

5650 KG

-

Model Number:

-

GSII-L1530-PMAX-85A

-

Plasma Power:

-

Powermax85 USA

-

Gantry type:

-

Table

-

Effective Cutting area(Length):

-

1500mm

-

Effective Cutting area(width):

-

3000mm

-

run speed:

-

4000mm/min

-

Cutting positioning accuracy:

-

±0.5mm/m

-

Surface roughness:

-

Ra≤25μm

-

CNC controller:

-

AI, DST, DWG, DXF, DXP, LAS

-

Servo motor:

-

Software Supports HPRXD and True Hole

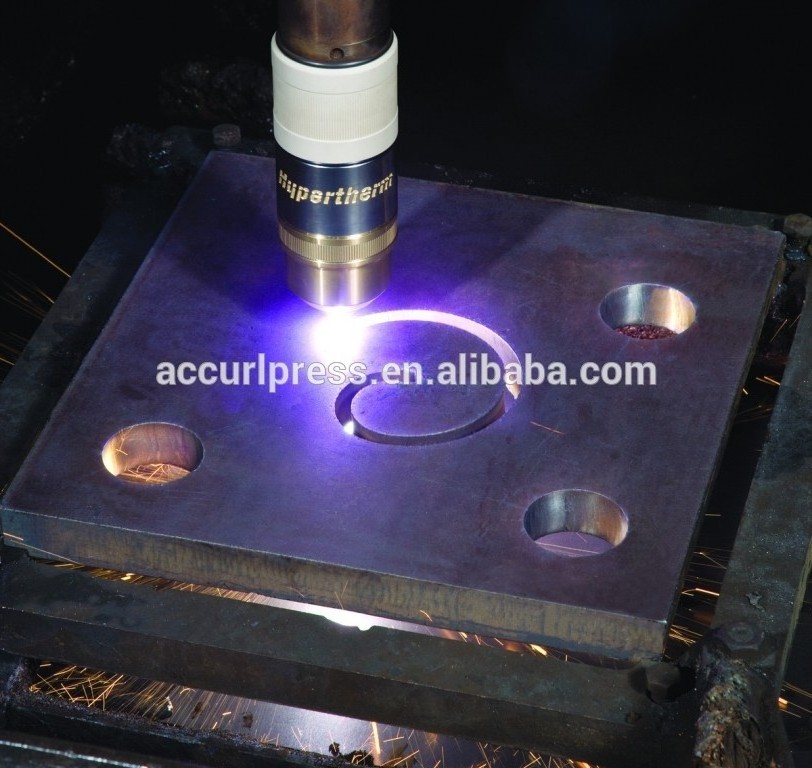

Product Application

The Micro EDGE Pro CNC cutting system is designed to be reliable, cost-effective, and meet your high performance cutting requirements. The Micro EDGE Pro CNC series are built to ensure a smooth and accurate performance. It is equipped with a Hypertherm cnc control system, precision linear guide ways and self aligning plasma torch collision device, automatic height control and automatic ignition system.

The ACCURL base, consists of welded profiles over the entire length which result in an extremely rugged machine frame. The gantry of the machine rests on oversized linear guides, mounted on the welded profiles, and is driven by two brushless AC Servo motors with rack-and-pinion system (double X-axis drive).

Perfect parallel movement:

The correct positioning is assured by high-resolution encoders, directly mounted on the motors. The synchronised system of the two motors assures perfect parallel movement of the gantry over the linear guides. Cutting Table: dry sectionized downdraft or water table is separately from the rails.

Automatic height positioning:

The ACCURL's gantry can accommodate multiple stations such as plasma and/or oxy torches. Included is a MicroEDGE Pro CNC Control unit, monitoring the Z-axis (by brushless AC Servo motor) for the automatic height positioning of the torch during the cutting process.

During the cutting process, the MicroEDGE Pro CNC unit measures the Arc Voltage and adjusts the Z-axis height to maintain a constant distance from the sheet for optimum cutting results.

Correct cutting height:

Each oxy-fuel torch carrier has an automatic flame ignition for the torch, as well as an integrated capacitive sensor

"Hypertherm OHC" that controls the Z-axis movement (by brushless AC Servo motor ) for correct setting of the cutting height.

Main Features

The machine is equipped with the Hypertherm Micro Edge Pro touch screen CNC with easy to use functions such as: Cutpro wizard, cutting optimization tips, built in process databank allowing the operator to select the material type and thickness.

→Portable monoblock construction with small footprint.

→Easy installation,

→Dual side AC servo Y motorization with direct planetary gear box, helical rack and pinion drive system

→Precision Linear Rail Guide Ways in X and Y axis

→High speed torch lifter with automatic arc voltage height control

→Fully enclosed hose and cable carriers

→Hypertherm Micro Edge Pro CNC

→Integrated downdraft table with CNC electro pneumatic multi zone selection

→Integrated dross bins

→Magnetic Torch anti collision protection system

→Laser pointer for plate alignment

→CE safety specifications

Machine Parts

Name: Machine Body

Brand: ACCURLOriginal: CHINA

a.the steady gantry framework provides an open worktable

b.Synchronous X/Y/Z axes: The Z-axis can run 150mm,

suitable for cutting many varieties of metal sheets.

c.High quality guarantees its durability and easier maintenance.

Drive System

Name:

Servo Drive & Motor

Brand:

YASKAWA

Original:

JAPAN

The imported servo motor (Y-axis driven by two servo

motors) along with the sophisticated planetary reducer

ensures steady, precise and reliable drive.

Machine Parts

Name:

Rack and linear guide

Brand:

YCC

Original:

TAIWAN

Advanced cutting system, laser power and servo movement suit each other perfectly, imported high precision gear and rack drive system, exchangeable double work table, to ensure higher processing speed and accuracy.

Main Features

Brand: Hypertherm

Original: America

PMX125 US Treasure plasma power; maximum perforation thickness: 25mm; Cutting edge thickness: 38mm; section verticality: ≤5 degrees; section Roughness: Ra≤12.5μm; cutting speed 3000mm / min (based on the specific cutting speed cutting steel The thickness is determined, see instructions)

Pre-Sales Service

* Technical solution.

* Online video authentication machine work.

* Cutting samples provided by DHL.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

CNC Press Brake

91.8% Response Rate

500W Laser Cutting Machine

91.8% Response Rate

6000W Laser Cutting Machine

91.8% Response Rate