1).automatic vertical single head uncoiler : 1 set

a.Using hand tightening design, Coil ID:460mm-520mm, coil OD:1400mm, Loading:2000kg

b.Frequency conversion automatic uncoiling

c.Power:2.2KW

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sussman

-

Voltage:

-

380V, 50Hz, 3 phase (can be customized)

-

Power:

-

7.5kw

-

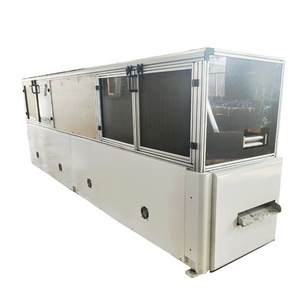

Dimension(L*W*H):

-

4.5m*0.8m*1.0m

-

Weight:

-

3000 kg

-

Rolling thinckness:

-

0.6-1.2mm G350-G550MPa

-

Feeding width:

-

142 mm ,220mm or customized

-

Roller material:

-

45#steel Chrome Plated

-

Main power:

-

7.5KW servo motor

-

Hydraulic motor:

-

7.5KW

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller station:

-

11 stations

-

Control system:

-

Fully Automatic Computer Control

-

Product Keywords:

-

light steel framing machine

-

Design software:

-

Vertex BD Software

Quick Details

-

Marketing Type:

-

cheaper price

-

Work Pressure:

-

15KW

-

Production Capacity:

-

15-30m/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sussman

-

Voltage:

-

380V, 50Hz, 3 phase (can be customized)

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

4.5m*0.8m*1.0m

-

Weight:

-

3000 kg

-

Rolling thinckness:

-

0.6-1.2mm G350-G550MPa

-

Feeding width:

-

142 mm ,220mm or customized

-

Roller material:

-

45#steel Chrome Plated

-

Main power:

-

7.5KW servo motor

-

Hydraulic motor:

-

7.5KW

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Roller station:

-

11 stations

-

Control system:

-

Fully Automatic Computer Control

-

Product Keywords:

-

light steel framing machine

-

Design software:

-

Vertex BD Software

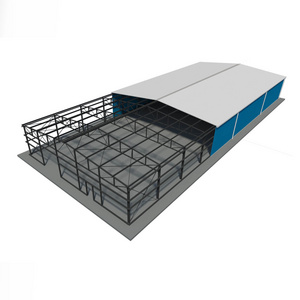

Light gauge steel framing is a construction method that cold formed steel sections to create a structural framework for buildings, which at its simplest is an assembly of columns and beams.

Cold formed steel sections include steel studs, tracks and joists that are assembled together to form the load bearing skeletal structure. However It can also be used to create interior partitions and non-load bearing walls, or curtain walls.

|

Thickness

|

0.7-1.2mm(G300-G550Galvanzied coils and Aluzinc )

|

|

Feeding width

|

About 182mm

|

|

Standard Producing speed

|

About 300-700m/h

|

|

Max producing speed

|

About 1500m/h

|

|

Main motor

|

7.5kw Servo motor

|

|

Power supplier

|

220V 60Hz 3phases according to your request

|

|

Hydraulic station

|

7.5kw Motor

|

|

Hydraulic tank capacity

|

About 100L

|

|

Hydraulic cooling

|

Fan cooling with Accumulator

|

|

Hydraulic pressure

|

Manually set

|

|

Host cordless remote control

|

Standard

|

|

Frame and punching dies

|

Screw hole, chamfer, web hole, flange cut, pipe hole, suspension, cutting,

|

|

Product accuracy+-

|

0.5mm

|

|

CNC inkjet-printer

|

Inter jet printer Video jet

|

|

Size

|

About 4700*950*1200mm

|

|

Weight

|

About 3500kg

|

|

Color

|

Standard or according to your request

|

|

De-colier

|

Bearing 2 tonne, automatically decoiler

|

|

PLC

|

Panasonic brand

|

|

Electrical parts

|

Schneider brand, encoder:Omron

|

Automatic decoiler

main roll forming machine

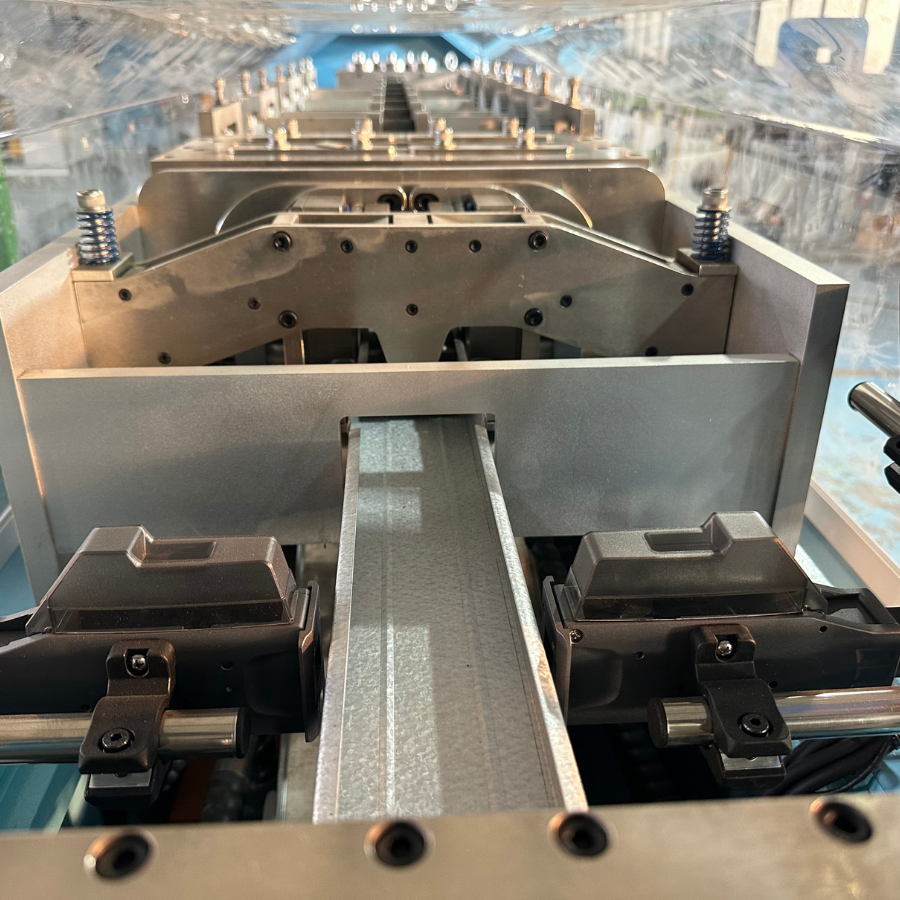

1). Frame: Using steel plate welding, the overall annealing to stress treatment, to ensure long-term use without deformation; and CNC machining center processing to ensure dimensional accuracy.

2). Rolling mould: Cr12mov die steel, after vacuum hardened HRC60-62 ° to refine the hole and the end of the face, CNC lathe

finishing the roller surface.

3). Drive system: Servo motor and reducer linkage, between the wheel with precision hard tooth gear oil immersion operation, to

ensure that the use of long time without wear.

4). Punching mould

Die model material are used S45C tool steel, mold insert with D2 or SKD11 high-quality steel, mold parts with Japan's rice

products.

2). Rolling mould: Cr12mov die steel, after vacuum hardened HRC60-62 ° to refine the hole and the end of the face, CNC lathe

finishing the roller surface.

3). Drive system: Servo motor and reducer linkage, between the wheel with precision hard tooth gear oil immersion operation, to

ensure that the use of long time without wear.

4). Punching mould

Die model material are used S45C tool steel, mold insert with D2 or SKD11 high-quality steel, mold parts with Japan's rice

products.

control system

Control Device:One laptop, a control box inside of based frames of the machine

Design Software: Vertex BD from AU

Printing Device: USA Printing Device for spray logo and installation number

Remote-control Device:Wireless remote-controller controls machine to go forward or back or stop

Main brand: PLC(Delta),Relay(Schneider),Proximity switch(Schneider),Encode(Omron) Servo Motor

LGS framing is commonly used for commercial and multifamily residential buildings, and it is seeing a rise in single family residential applications as well.

To prevent fire damage, steel is coated with zinc or a combination of zinc and aluminum, also referred to as “galvanized” steel. This protective coating safeguards the steel from corrosion. The thickness of the coating depends on the intended environment of use. For instance, steel pieces intended for humid settings require a thicker coating, while those in drier regions can have a thinner coating.

Key features of Light Gauge Steel Framing include:

Cold-Formed Steel Sections: The steel used in light gauge steel framing is typically in the form of coils or strips, often galvanized for corrosion resistance. These steel sections are then cold-formed into various shapes, such as studs, tracks, channels, and joists, through a series of rolling and shaping processes.

Lightweight and High Strength: Light gauge steel members are thinner and lighter compared to traditional hot-rolled steel sections. Despite their lightweight nature, they offer high strength and structural integrity, making them suitable for various construction applications.

Versatility in Design: Light gauge steel framing allows for flexible and innovative design options. The material's strength-to-weight ratio enables the creation of open and spacious interiors without the need for excessive support columns.

Precision and Consistency: The cold-forming process ensures precise dimensions and consistent quality of the steel sections. This precision contributes to accurate assembly and construction.

Rapid Construction: Light gauge steel framing is known for its speed of construction. Components are typically pre-engineered and can be manufactured off-site, leading to faster assembly and reduced construction timelines.

Fire Resistance: Steel is inherently fire-resistant, and light gauge steel framing can contribute to the fire safety of a building. Additionally, gypsum-based board materials are often used with LGSF to enhance fire resistance.

Resistance to Pests and Rot: Unlike wood framing, light gauge steel is not susceptible to pests, such as termites, and does not rot. This feature contributes to the durability and longevity of structures built with light gauge steel framing.

Hot Searches