- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Clients Local Standard

-

Dimension(L*W*H):

-

Diffrent Model

-

Weight:

-

1100 KG

-

Application:

-

Gold recovery

-

Installation:

-

Under Guidance

-

Feeding size:

-

0.075-2cm

-

Color:

-

Customers' Requirements

-

Material:

-

Carbon Steel

-

Capacity:

-

0.5-2 Tons/hour

-

Market:

-

Africa, Mexico

-

Usage:

-

Mining Separatoion

-

Keywords:

-

Hot sale ore beneficiation spiral chute with low consumption for sale

-

Name:

-

ore beneficiation spiral chute

Quick Details

-

Production Capacity:

-

above 98%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Voltage:

-

Clients Local Standard

-

Dimension(L*W*H):

-

Diffrent Model

-

Weight:

-

1100 KG

-

Application:

-

Gold recovery

-

Installation:

-

Under Guidance

-

Feeding size:

-

0.075-2cm

-

Color:

-

Customers' Requirements

-

Material:

-

Carbon Steel

-

Capacity:

-

0.5-2 Tons/hour

-

Market:

-

Africa, Mexico

-

Usage:

-

Mining Separatoion

-

Keywords:

-

Hot sale ore beneficiation spiral chute with low consumption for sale

-

Name:

-

ore beneficiation spiral chute

|

Describe: |

|

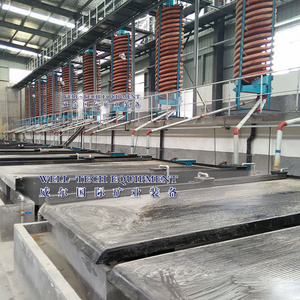

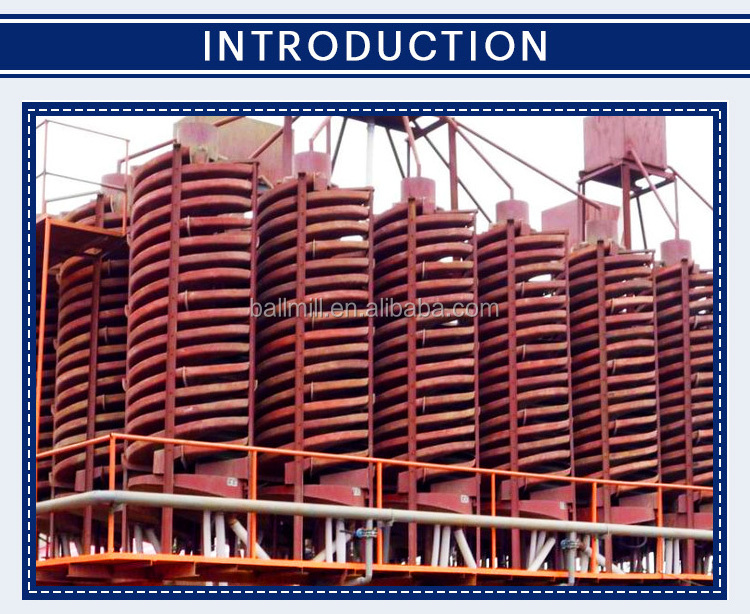

The spiral chute is a new type of mining and mineral processing equipment developed by combining the advantages of spiral concentrator, shaking table and centrifugal concentrator. It is especially suitable for sand mining.

|

|

Advantage: |

|

1. The spiral chute sorting process is stable and easy to control. 2. No power, large processing capacity, small investment and quick effect. 3. Simple structure, small floor space, easy installation and easy operation. 4. The allowable variation range of ore concentration is large, the enrichment ratio is high, and the recovery rate is high.

5. Low water consumption, low power consumption and low total production cost.

|

|

Note: |

|

The spiral chute is suitable for sorting iron ore, ilmenite, chromite, pyrite, zirconium, rutile, monazite, phosphorite, tungsten ore, tin ore, tantalum ore, niobium ore with fine particle size of 0.3-0.02mm and other non-ferrous metal, rare metal and non-metallic ore objects with specific gravity difference. |

|

Model |

LL2000 |

LL1500 |

LL1200 |

LL900 |

|

Outside diameter (mm) |

2000 |

1500 |

1200 |

900 |

|

Inside diameter (mm) |

360 |

250 |

220 |

180 |

|

Spiral distance (mm) |

1200 |

900/675 |

720/540 |

5540/360 |

|

Angle of inclination (°) |

9° |

9° |

9° |

9° |

|

Spiral number |

2-4 |

2-4 |

2-4 |

2-4 |

|

Cylinder number |

3.5 |

4 |

4/5 |

4/5 |

|

Feeding size (mm) |

0.4-1 |

0.03-1 |

0.03-0.3 |

0.03-0.3 |

|

Pulp concentration |

20-45 |

30-45 |

30-50 |

30-50 |

|

Capacity (t/h) |

15-40 |

8-16 |

4-6 |

2-3 |

|

Floor area (m 2 ) |

5.7 |

3.3 |

2 |

1.2 |

|

Height |

6.6-8 |

5.5 |

5.23 |

3.2 |

|

Working principle: |

|

Will spiral chute stand, calibration of vertical line, with metal or wood fixed in place, a sand pump will ore to screw on the top two inlet, to join the replenish water, adjust the pulp density, pulp natural swirl, down from a high in the rotating velocity can produce a kind of inertial centrifugal force, with the proportion of ore, the difference of particle size, shape, through the effect of gravity and centrifugal force cyclone, separate mines with sand, concentrate into a pipe with pipe joint, backfilling pipeline receives sand pool, backfilling materials flow into the bucket with sand pump discharge, to complete the whole process of ore dressing. |

|

Packaging detail: |

|

Standard containers, bare main machine, motors and small parts are packed in wooden cases. |

|

Delivery port: |

|

Within 45 days Qingdao,Shanghai,Tianjin and other ports. |