- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

customize

-

Power:

-

61kw

-

Dimension(L*W*H):

-

9000*2250*2200mm

-

Weight (KG):

-

11000

-

After-sales Service Provided:

-

Free spare parts

-

moisture sensor:

-

weighing system

-

dewatering:

-

one button control technology wood dryer machine

-

cooling in tank:

-

condensation system

-

Product name:

-

wood dryer machine

-

type:

-

PLC control system

-

cooling type:

-

stainless steel water-ring vacuum pump

-

controller:

-

PLC program

-

Keywords:

-

vacuum

-

Certification:

-

CE

Quick Details

-

Type:

-

Vacuum Drying Equipment

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SAGA

-

Voltage:

-

customize

-

Power:

-

61kw

-

Dimension(L*W*H):

-

9000*2250*2200mm

-

Weight (KG):

-

11000

-

After-sales Service Provided:

-

Free spare parts

-

moisture sensor:

-

weighing system

-

dewatering:

-

one button control technology wood dryer machine

-

cooling in tank:

-

condensation system

-

Product name:

-

wood dryer machine

-

type:

-

PLC control system

-

cooling type:

-

stainless steel water-ring vacuum pump

-

controller:

-

PLC program

-

Keywords:

-

vacuum

-

Certification:

-

CE

Product Application

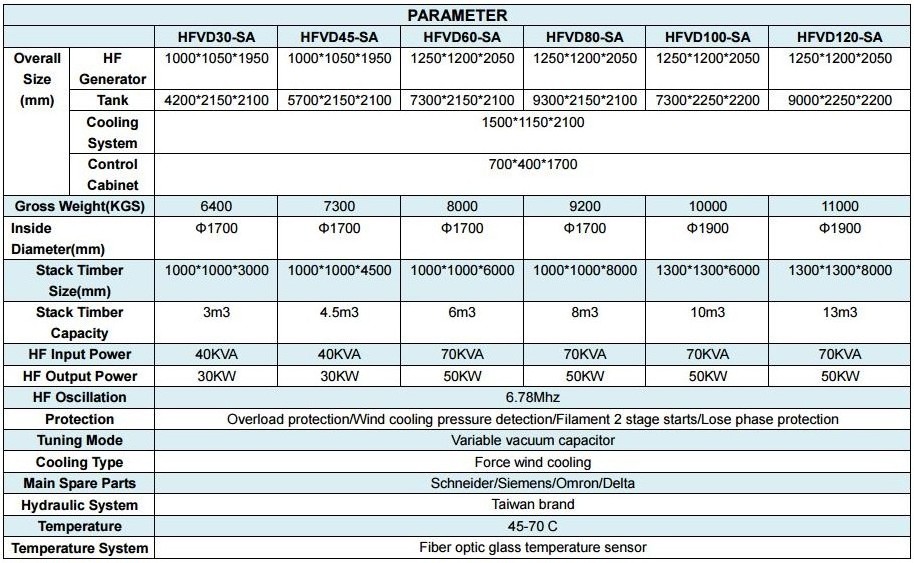

High frequency vacuum wood dryer is small capacity but rapid with low temperature drying machine, suitable for drying all kinds of wood, from veneer/ lamella/ wood board to thick lumber, second time balance humidity, even large dimension heavy timber for wooden house.

* For thin pieces, like veneer or floor lamella, HF vacuum drying technology not only offers short cycle solution, but also eliminates curved or shrink problem.

* For thick and hard wood, HF vacuum dryer brings good quality with uniform humidity, free of split or spark both on surface and core, short drying cycle will help a lot to meet demand or production.

Principle of HF vacuum wood drying

High frequency vacuum drying technology constitutes a combination of two special methods: heating by high frequency current and drying in vacuum where the boiling point of water is decreased with decreasing pressure.

1. High frequency heating:

High frequency power acts on the moisture in wood, it penetrates the wood, where there is water of moisture, there is high frequency power, so it can dry rapidly and uniformly.

2. Vacuum condition:

In vacuum condition, the water is vapored at very low temperature, it eliminates sparking or splitting problem for hard wood, especially extremely hardwood likely to spark if drying temperature is high.

Further more, vacuum condition creates a minus pressure in the dryer, the movement of water molecule through wood increases leading to shorter drying time then can be achieved at atmospheric pressure, minus pressure sucks water or moisture out of wood quickly.

Character of SAGA high frequency vacuum wood dryer

1. SAGA offers ONE BUTTON CONTROL technology

Full automatic drying program within PLC control system for different wood, the operator does not need to have much knowledge about wood drying to cook the wood perfect.

2. Precise and reliable monitoring system

High precise and stable monitoring spare parts will always guide on machine both for warranty of good drying quality or safety of personal and machine.

3. Well selected spare parts

High grade stable spare parts are chose which is tested for long time for machine and make sure stable running and problem free.

4. Logical and safe design

With more than 20 years of experienced engineer, customers can expect a more logical and humanistic machine that is easy to use, run stably and help a lot in production.

Advantage of HF vacuum wood dryer

1. Short drying time: according to different timber, drying speed is 1~5 times than conventional wood kiln.

2. Good drying result: uniform humidity, stress elimination, no cracking/ bending/ shrink/ deformation problem, more stable and less waste.

3. Easy operation: using Saga smart control system, no need much knowledge of wood and drying experience. Only set all data into PLC touch screen, one button starts, and stop automatically, no need to adjust and guide in day and night.

4. Less space: can be installed in workshop.

5. Environmental: the power is electricity, no need boiler or other heating source, no pollution.

6. Saving labor: no need operator to guide all the time, no sticks between wood boards, saving labor and time.

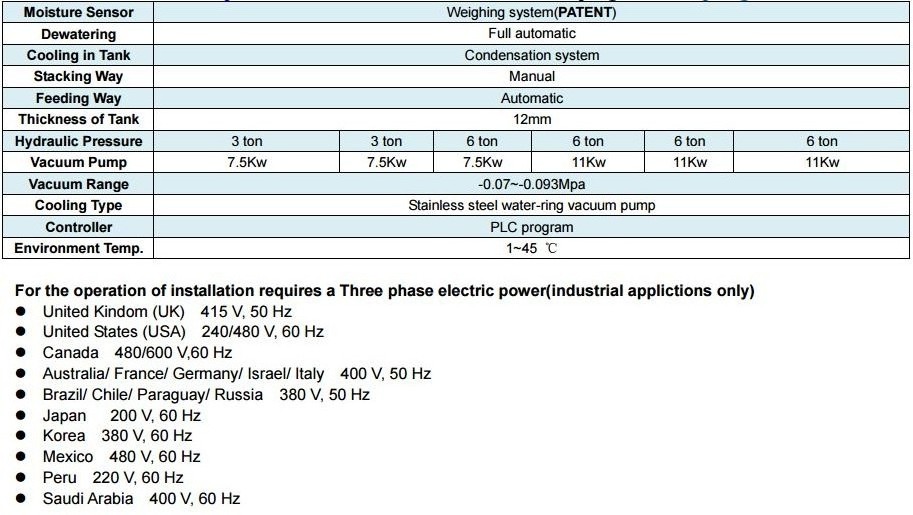

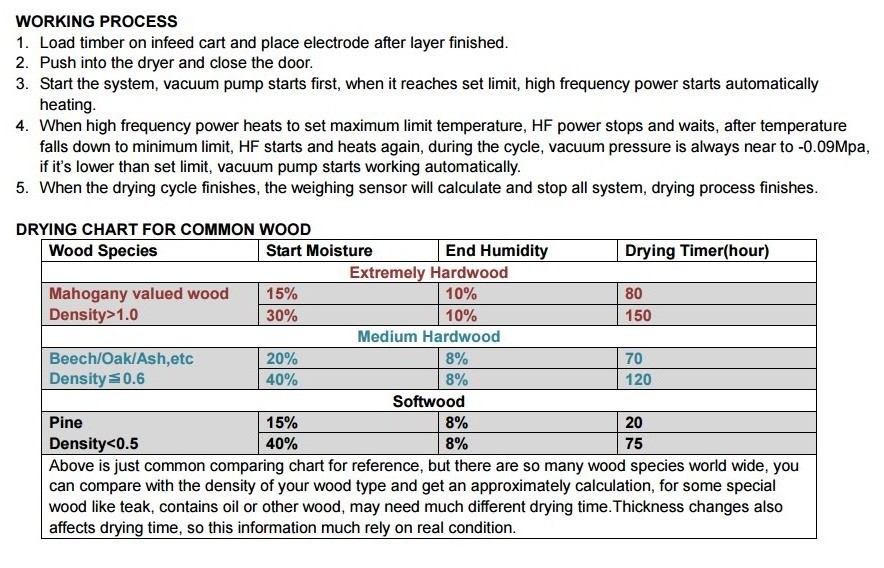

Real time humidity detection, based wood moisture calculating formula

Principle of moisture detecting is calculating by water evaporation. Set start moisture into PLC touch screen, the program calculates how much water should be dried out, when the moisture gets to goal end humidity, HF vacuum dryer stops automatically.

> Normal metal temperature sensor is effected by high frequency power and only can check moisture in one piece.

> It cannot be reference if only weight the water out of drying machine, it is not precise, because moisture cannot be collected.

> If don't put weighing sensors under the dryer, have to pull out to measure the weight of wood, it cannot detect the present moisture in drying process.

Calculating present moisture by weighing system is our patent, it can check the weight of moisture and water out of wood, Saga full automatic system can calculate the moisture precisely. We use knuckle bearing with weighing sensor to make sure the accurate weight.

SAGA smart high frequency vacuum drying technology

Saga Machinery Co., Ltd is first one who has designed and developed full automatic HF vacuum drying technology in China, we have nearly 10 years experience and already got an easy operating drying process, it can instead of experienced person, no need to guide. There are 40 different wood drying experience in Saga full-auto drying program.

Doing Research in BIO BIO University in Chile.

Control Panel with Program

BLE Infeet and Outlet Cart - saving space

Cooling System- stainless steel power, vacuum pump, water pump

High Frequency Edge Gluer

91.8% Response Rate

HF Curved Plywood Press

91.8% Response Rate

HF Universal Smart Framer

91.8% Response Rate

Straight Line Rip Saw MJ163

91.8% Response Rate

CNC Door Frame Milling Machine

91.8% Response Rate

Straight Line Rip Saw MJ153F

91.8% Response Rate

1.What is your price term and payment term?

We offer FOB, CIF, CNF EXW price, we accept TT/LC or other negotiate.

In stock:

100% payment;

Not in stock:

30-40% deposit for confirm the order, rest is paid before shipment, some customized machine may need 50% deposit.

2.How long for delivery?

Some standard machine or commercial machine, always in stock, for high value machine or customized machine, may takes

30-40 days production.

3.After sale and warranty?

Most machine got 1 year warranty except some consumption spare, all spare within warranty period is free for change, in the condition that machine is running according to the manual book(saga got rights for explain).

4.Installation for complex machine.

We have 20 years of experience for installation all over the world for big and complex machine, customer response for food and living as well as transport, some area may be served by our agent. For commercial machine, we will do our best to offer installation guiding video.

5.Free spare parts for change.

Most of our machine use international standard, especially electric spare parts, if not, we offer free spare parts to avoid any urgent condition to minimize risk of downtime.

6.Safety for the machine and packing.

We have mature experience for sea transport packing, for some irregular shape machine, we will do special fix and tight on container to avoid any risk of any broken.