- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Warehouse

-

Place of Origin:

-

China

-

Product name:

-

Steel Structure Buildings

-

Drawing design:

-

SAP2000/AutoCAD /PKPM /3D3S/TEKLA

-

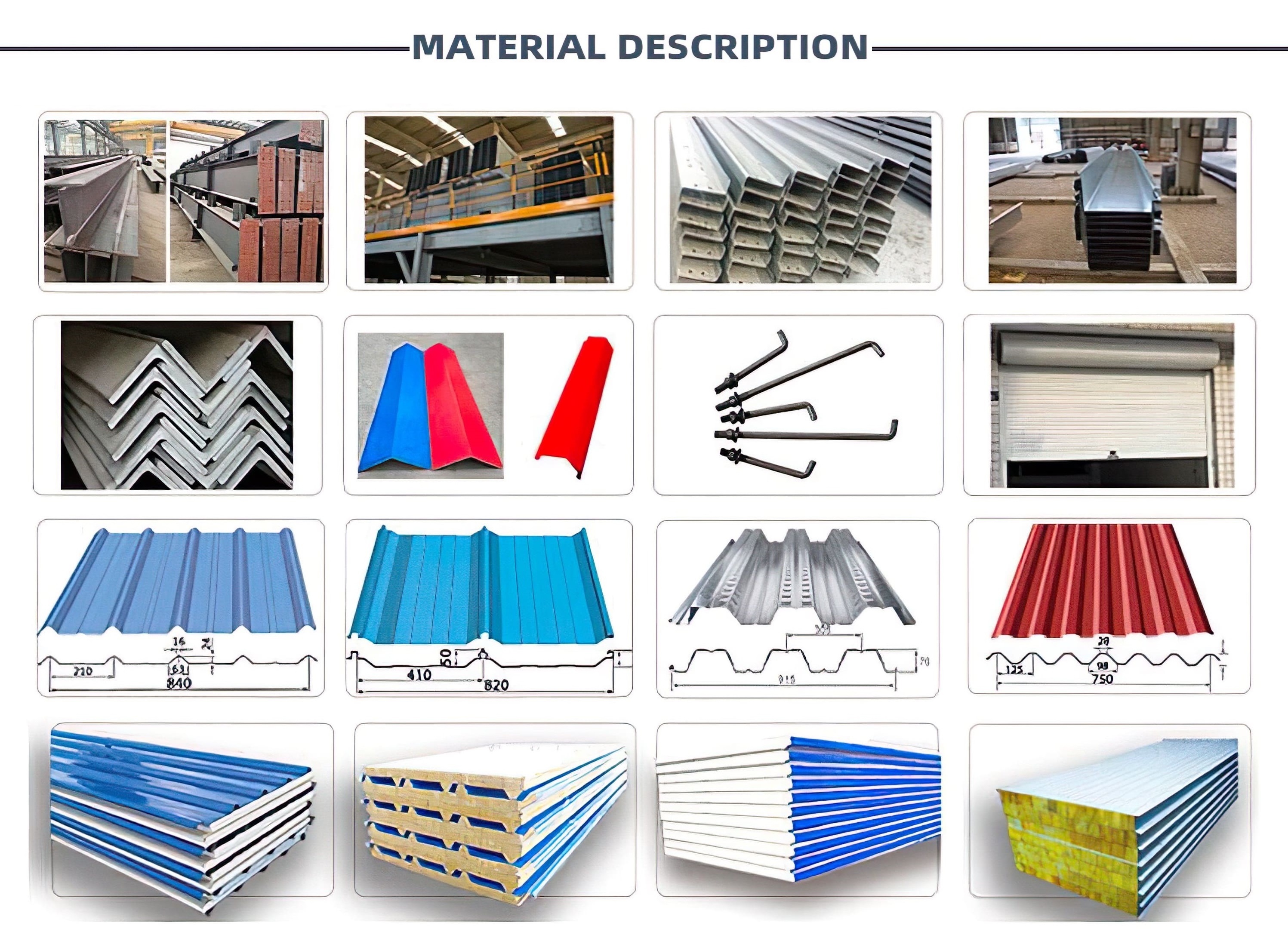

Main Material:

-

Q235/Q345/S275jr/S355/A36/A572

-

Surface treatment:

-

Sandblasting+Paint/Galvanize

-

Cladding:

-

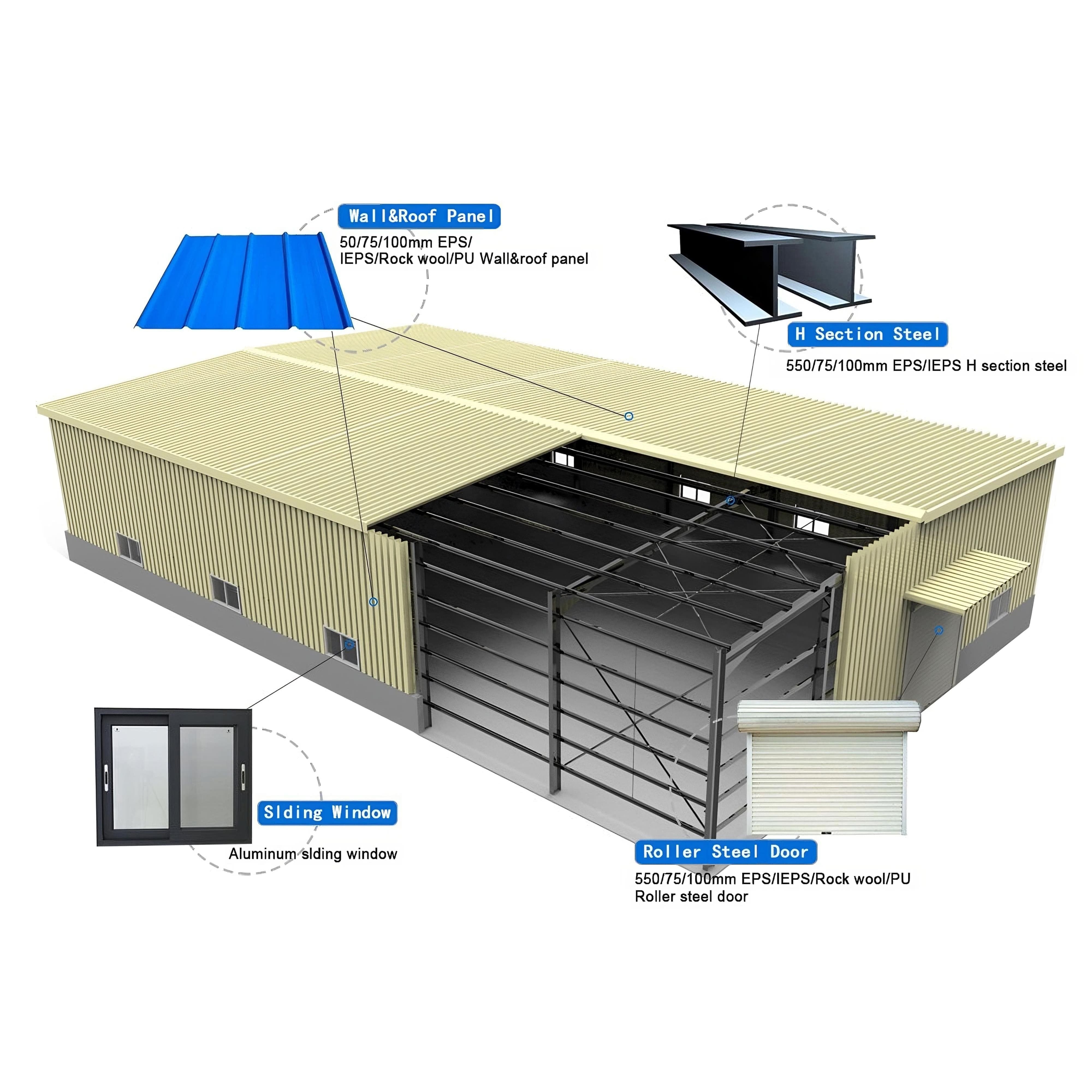

EPS/PIR/PU/Rock Wool Sandwich Panel

-

Purlin:

-

C/Z Galvanized steel channel

-

Installation:

-

Installation Drawing/Video Support/Onsite Support

-

Wind load:

-

Max 200 Km/h

-

Life span:

-

70 years

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Warehouse

-

Place of Origin:

-

China

-

Product name:

-

Steel Structure Buildings

-

Drawing design:

-

SAP2000/AutoCAD /PKPM /3D3S/TEKLA

-

Main Material:

-

Q235/Q345/S275jr/S355/A36/A572

-

Surface treatment:

-

Sandblasting+Paint/Galvanize

-

Cladding:

-

EPS/PIR/PU/Rock Wool Sandwich Panel

-

Purlin:

-

C/Z Galvanized steel channel

-

Installation:

-

Installation Drawing/Video Support/Onsite Support

-

Wind load:

-

Max 200 Km/h

-

Life span:

-

70 years

Click this button to contact our engineers to get a free 3D model of your project

Specification

|

Product

|

Steel structure processing

|

|

Type

|

Light

|

|

Tolerance

|

≤ ±1%

|

|

Processing Service

|

Bending, Welding, Cutting

|

|

Delivery Time

|

22-30 days

|

|

Application

|

Steel Structure Workshop Warehouse Commercial buildings Sheds

|

|

Drawing design

|

SAP2000/AutoCAD /PKPM /3D3S/TEKLA

|

|

Main frame

|

Steel Q355B Q235B /S275 S355/A36 A572

|

|

Surface treatment

|

Sandblasting+Paint/Galvanized

|

|

Cladding

|

EPS/PU/Rock Wool Sandwich panel

|

|

Color

|

Customized Color

|

|

Purlin

|

C/Z Galvanized steel channel

|

|

Installation

|

Installation Drawings/Video Support/Onsite Support

|

|

Life span

|

30-50 Years

|

Product Description

Technical Research

Professional Team

We has a design department and a research and development department, and has established independent and comprehensive steel structure engineering design, optimization, and deepening design control.

Informatization Support

We centralized dynamic control of the entire process of order design, production, and installation, and established a management and control integration model of "supervision, management, and control", and achieved full traceability of product component cycles.

Intelligent Manufacturing

Fire Flame Cutting Machine

CNC automatic cutting, no error except a small amount of thermal deformation

Laser Cutting Machine

CNC automatic cutting,no error no deformation

Assembly Machine

Semi-Automatic

Gantry Welding

Semi-Automatic Welding H-beam

Sandblasting

Meet Chinese and international standards

Painting Station

Environmental protection and high efficiency

Project Cases

Packing & Delivery

Professional packaging and loading processes, as well as guidance on loading and unloading, to ensure safe delivery and protection of products.

Logistics system: A comprehensive global logistics partner system.

Logistics services: Provide a complete set of logistics services.

Welded H-beam frames are used to package steel structure components, ensuring stability. Each container utilizes a steel frame weighing about 2 tons.

If you lack experience in unloading, we will provide guidance through illustrations and videos.

Customer Photos

Weifang Jinshang trading Co.,Ltd.

We are a wholly-owned subsidiary of Weifang Changda construction group.The group's prefabricated construction industry development is prominent, including Changda Construction Technology Industrial Park, Changda Green Technology Industrial Park, Jinshang Processing Workshop, and Machines & Facilities Company Workshop, forming four prefabricated industry bases. The group has carried out extensive international cooperation and has undertaken a large number of overseas construction tasks. Its construction footprint spans Asia, Africa, Oceania, and Latin America.

Certifications

FAQ

1. who are we?

We are a wholly-owned subsidiary of Weifang Changda Construction Group, which is the largest construction company in Weifang.

Since 2009, we have specialized in designing, processing, and installing steel structure projects.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Container house,Light section steel structure,Heavy steel structure,steel structure building,steel structure processing

4. why should you buy from us not from other suppliers?

Our company stands as the leading construction group locally, boasting top-tier quality in foreign trade. Although new to this sector, we are dedicated to pursuing modest profits to broaden our reach into the international market.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: Cash,Escrow;

Language Spoken:English,Chinese,Arabic,Russian

We are a wholly-owned subsidiary of Weifang Changda Construction Group, which is the largest construction company in Weifang.

Since 2009, we have specialized in designing, processing, and installing steel structure projects.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Container house,Light section steel structure,Heavy steel structure,steel structure building,steel structure processing

4. why should you buy from us not from other suppliers?

Our company stands as the leading construction group locally, boasting top-tier quality in foreign trade. Although new to this sector, we are dedicated to pursuing modest profits to broaden our reach into the international market.

5. what services can we provide?

Accepted Delivery Terms: FOB;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: Cash,Escrow;

Language Spoken:English,Chinese,Arabic,Russian

Hot Searches