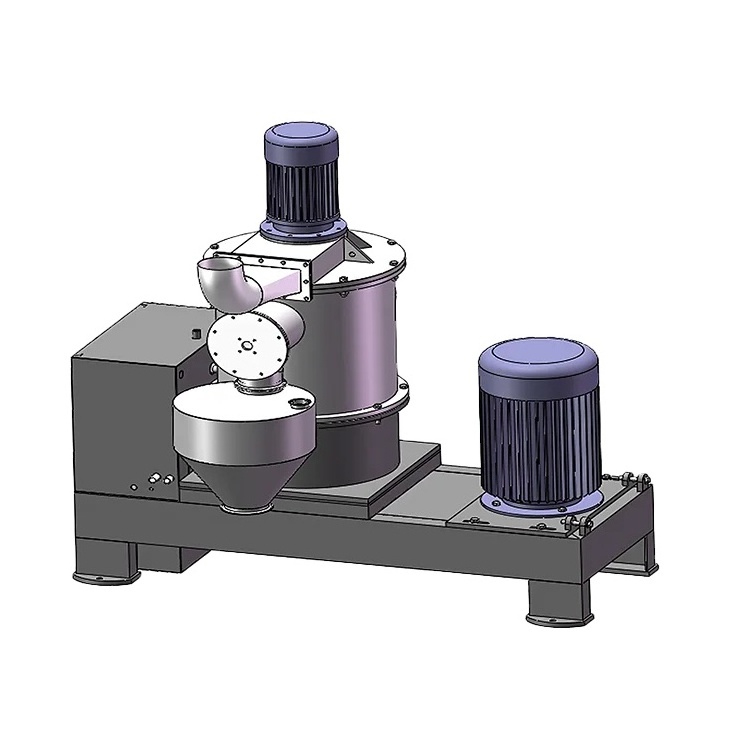

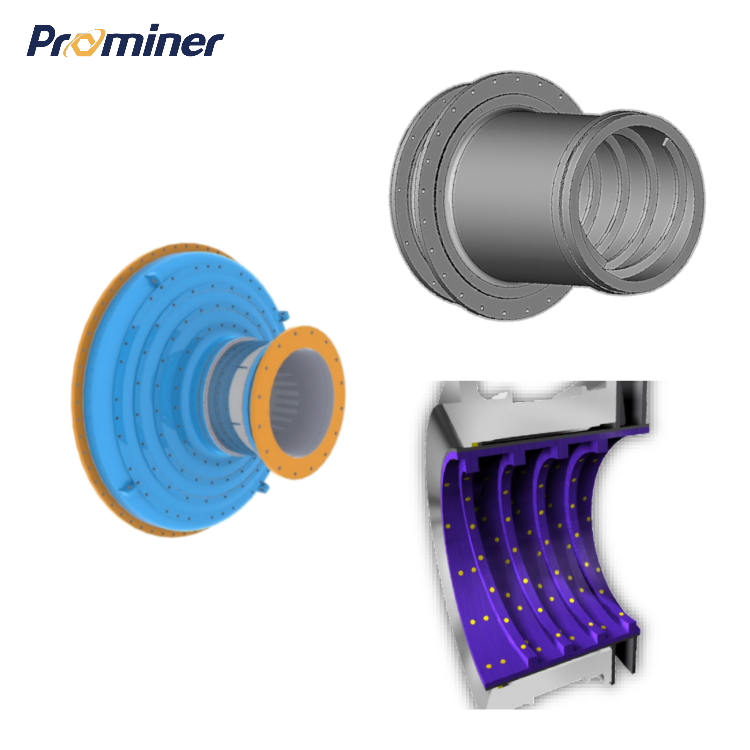

Capacity: 5-6000 kgs/h

Output Size: 5-100μm

Service:

Physical property analysis

Lab and pilot test

Complete grinding solution

On-site erection & commissioning and training.

Customization service by following the drawing from client

Application:

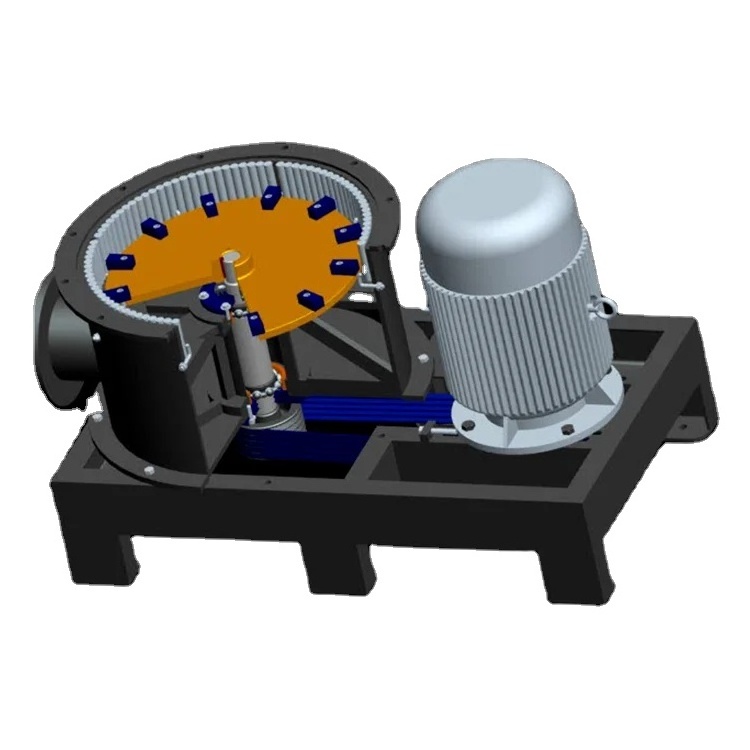

Making the sphercial graphite for anode material by grinding the green petroleum coke (GPC coke), green needle coke, calcined petroleum coke (CPC coke), calcined needle coke, coating pitch, natrual graphite. Grinding desulfurization agent and denitrification agent for boiler in cement factory and power station.

And carbon black, polyacrylamide,urea,sulphur etc.